Very nice print, iNF.

Shapr3D is a CAD App specifically designed to work on an iPad or a computer. I have been using it for a few months, and it seems very good, although I have only used 2D TurboCAD before and none of the others available.

3D printing is just brilliant. I can wake up with an idea in my head, then CAD it and set it printing to be ready that afternoon or the next morning. Even silly little things, such as A replacement lid for our bird feeder; Brackets to repair the clothes drying horse; A jockey wheel for a child's toy caravan, A holder for a set of specialised plumbing tool sockets which have a round profile but a large flat on one side, New plastic soft jaws for my crab clamp….The list goes on, and be warned; it gets addictive !

To make those in a machine shop would require a workshop and thousands of pounds worth of lathes, mills and tooling, plus I don't have the skills, experience or accuracy to work in metal. I don't know how you would even begin to cut the shapes for the plumbing sockets.

When you have a moment I would be interested in the advanced settings employed in your Cura if that's what you are using to slice:

Outer wall wipe distance, (0.3mm)

Infill wipe distance, (0.15 mm)

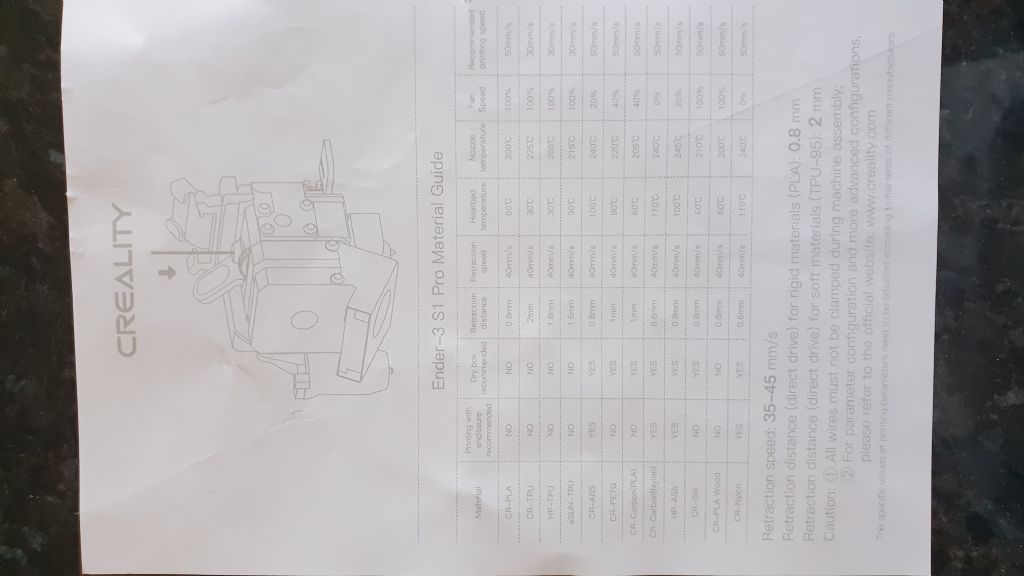

Retraction distance, (7.00mm)

Retraction speed, (25.0mm/s)

Retraction retract speed, (25.0mm/s)

Retraction minimum travel, (1.5mm)

My settings in brackets, for PLA filament.

With PLA I am getting a lot of stringing where the nozzle moves between elements on my prints, which require a lot of post print finishing, and I would like to reduce this.

I have not used ABS yet, but had trouble with PETG detaching, until I put the bed temperature up to 80°C.

Nylon was difficult, and really needs an enclosed print space apparently.

Justin Thyme.