Well, I was hoping for some ideas, but didn't expect this response!

Thanks guys for all the suggestions

Quick answers:

Martin,

I certainly won't be taking her out in winter, what with our salt laden roads, but it goes against the grain to see such bearings in the all-together.

I like your suggestions, so will be mulling them over and playing with bits of card whilst I do the bodywork.

Gordon,

I do have a tin of waterproof grease I intend using on exposed parts, but thanks for the suggestion nevertheless.

Nick,

That shaft only moves a few degrees, as it has all sorts of gubbins and levers secured to it, details in Phil P photos 6 & 7, and as mentioned by SB5, the airings need to accommodate the chassis flexing.

I have no idea what was designed to rotate in what, but hopefully Phil will be able to enlighten me/us.

Phil W,

Thanks.

Been thinking along those lines.

Can grease come into contact with the leather without damaging it?

BobH,

Petrol/diesel cars will no doubt be museum pieces in 80 years, but as usual I am no doubt going over the top in trying to protect those bearings, but that's me. Get it from my parents who where perfectionists.

Bl@@dy annoying this trait at times when inappropriate.

Zinc has been mentioned on the Friends Forum, so just going on what I read. Open to correction of course.

James,

Thanks for the link.

Phil,

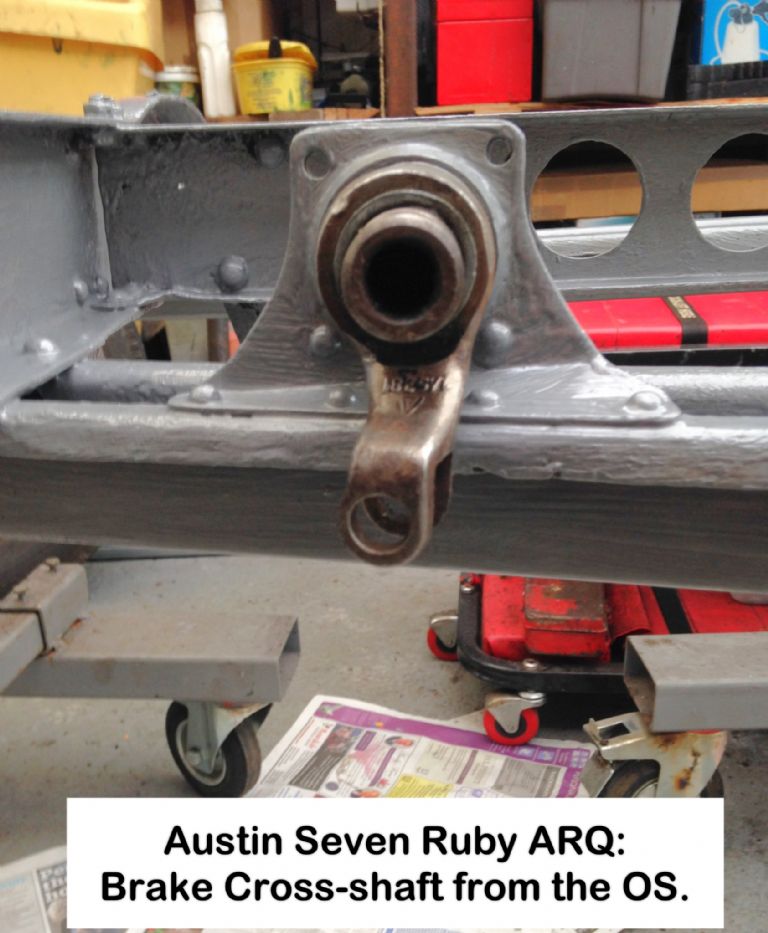

The big diameter OS tube on my shaft will not come off as yours has.

It appears to be pinned to the long inner one.

Have read everything I can find on these shafts and there is conflicting info as some say the shafts are welded to form one solid ones, then some saying the outer tube is free to rotate slightly, so I am totally confused.

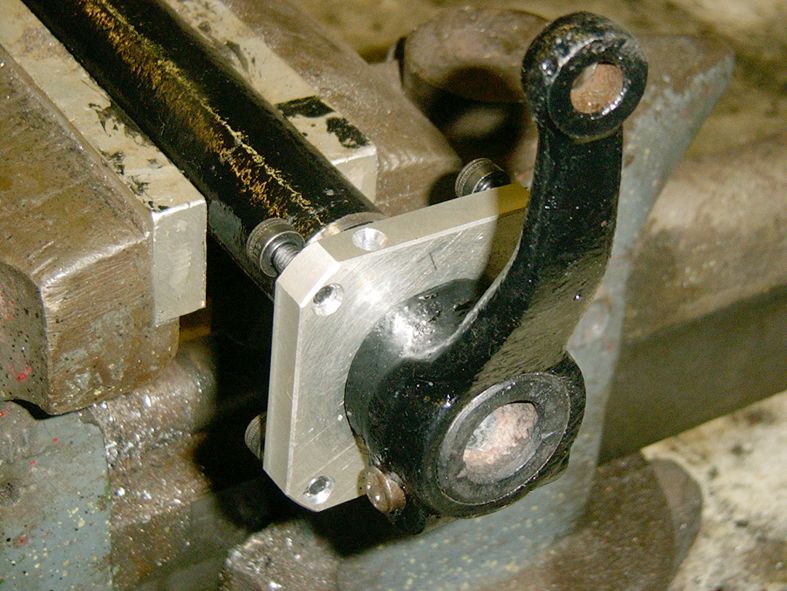

Nice mod to the shaft, but are you still using the double cone bearings?

I do like the way you have set-up the drums for skimming, so something to copy.

Photo of the tubes that make up my Ruby's Cross-shaft, there being a pin spanning the tube/s and possible outer ends visible on the outside, so mine appears to be locked solid.

As can be seen, the OS tube has been turned down to slide over the middle one, itself being turned down as well.

Confused as I said, so nothing new then.

Geoff – I could go on forever about iOS9 but won't bore everyone from now on.

Howard Lewis.

.

.