Posted by Aston Manning on 23/05/2023 22:02:49:

Hi all,

thanks for the replies.

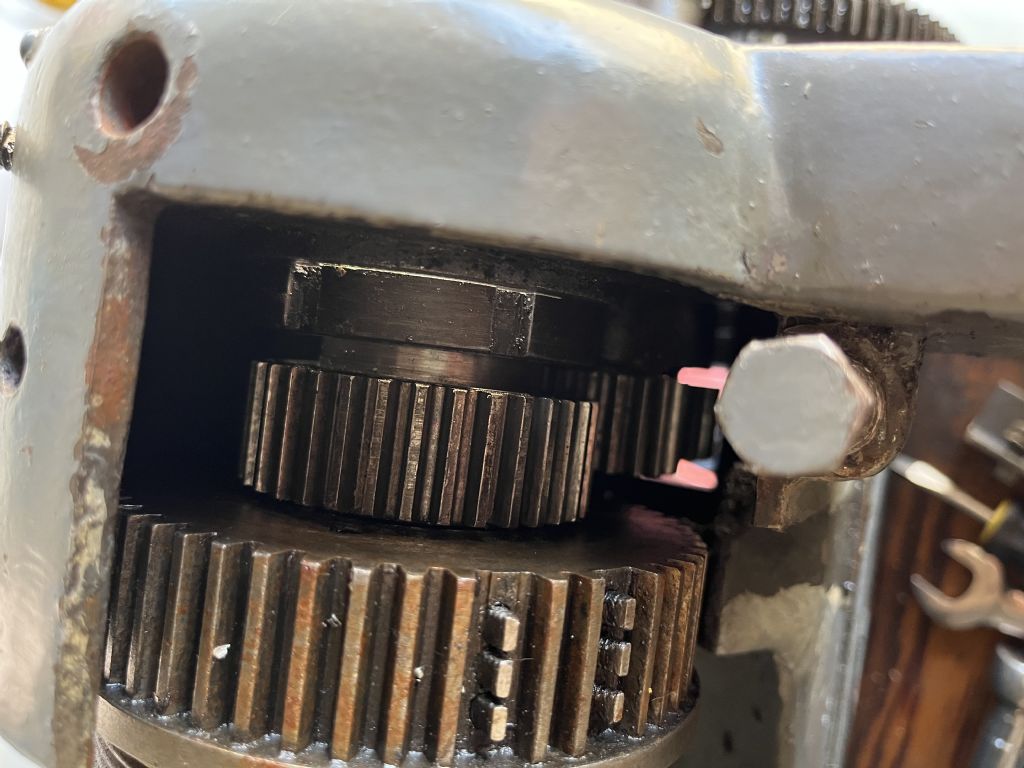

yes it has slotted ring nuts one which screws in to a bronze bearing sleeve furthest from the chuck and two closer to the chuck.I will get some better pictures tomorrow. I'm unable to remove the gear that is for the change wheels it is too close to the back gear to put anything in to prise it and I cant fit a removal tool in I think I have to remove that gear and the rest should come off of the spindle.

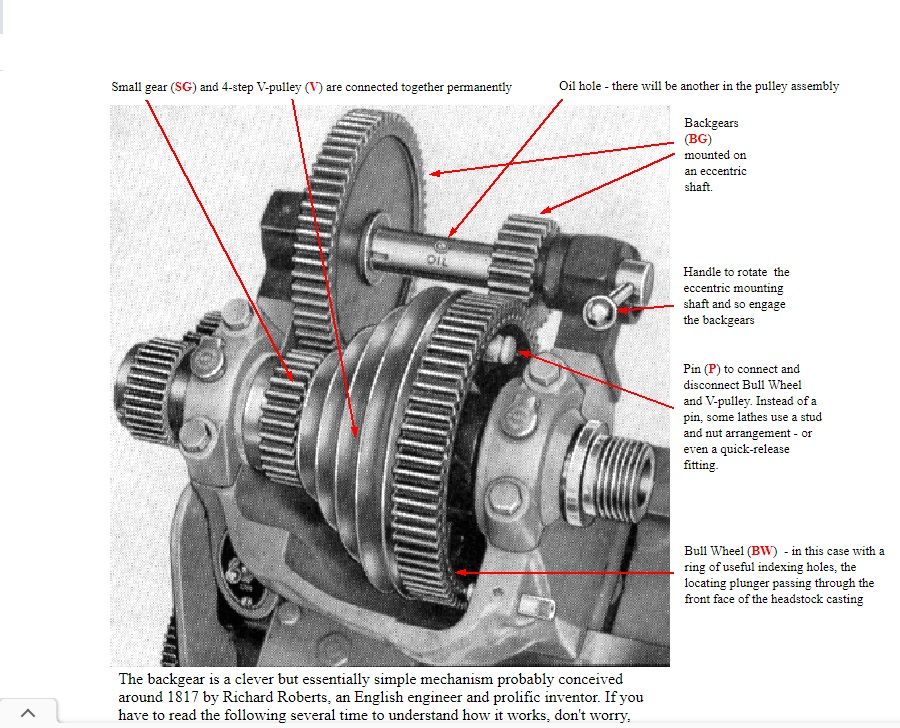

It's a similar set up to the picture below

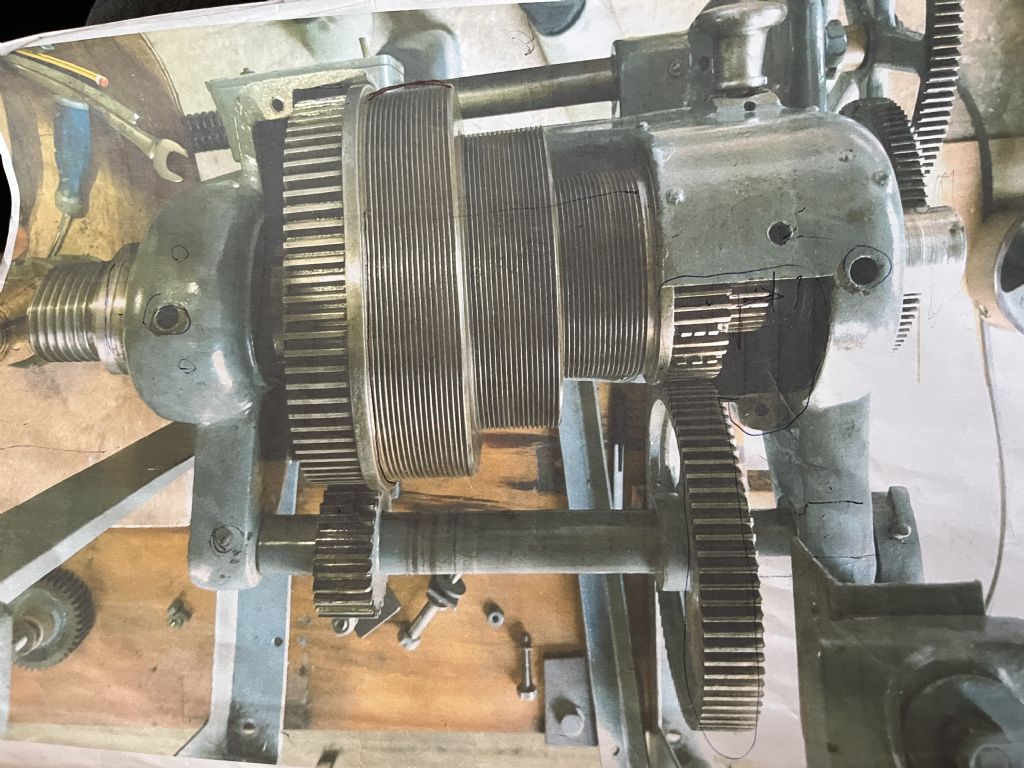

Judging by the pictures of your lathe the photo above is not at all similar as regards the headstock and spindle construction.

The link that Dave Halford gave (a few posts back) is much more relevant. It may not be identical as it does not have the back gear but if its the same make of lathe then the manufacturer will probably have used the same general design and there are enough clues in the drawing that will enable you to proceed.

It looks a really nice lathe and I suggest taking care and not rushing disassembly, hopefully there is a flat or dimple where the grubscrew sits so that any burr does not damage the front bearing (spindle must come out from the front)

Ian P

Aston Manning.