Posted by Nicholas Farr on 26/07/2023 11:20:53:

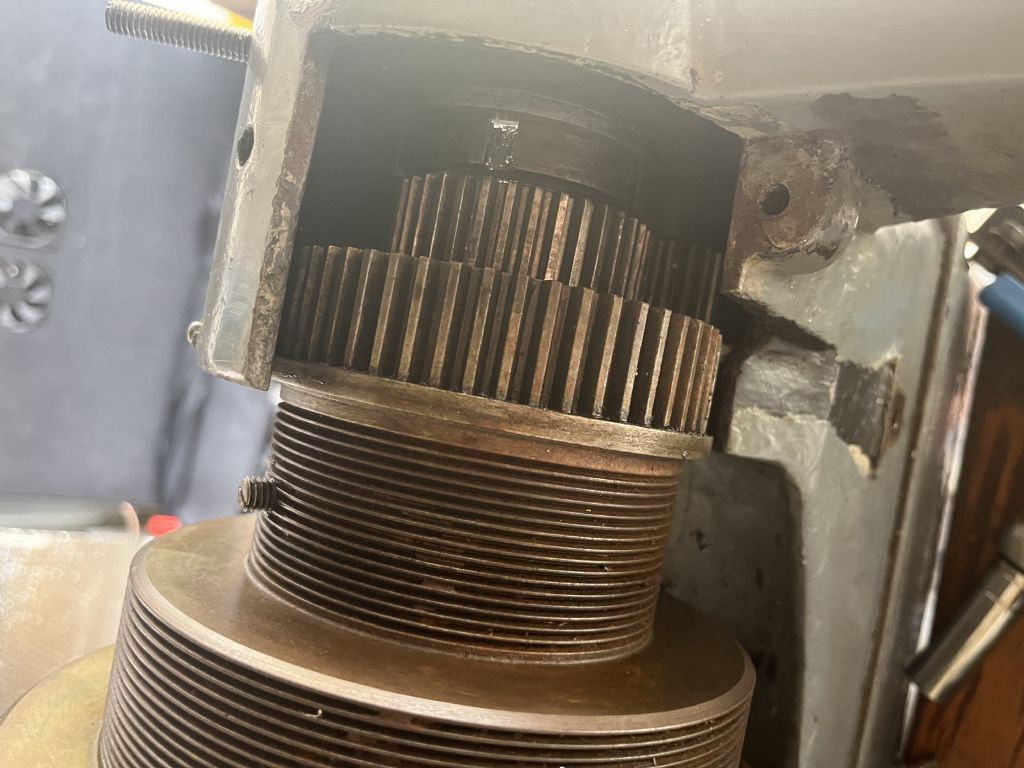

Hi Aston, shouldn't do any harm drilling it out, try one that fits in the hole first, but you need to get some idea as to how deep to drill it, as it's probably in a dimple, and you may need a solid carbide or cobalt drill bit if it's a hardened grub screw.

Regards Nick.

The hole shown in the picture appears to be in the headstock casting (bearing housing) so more likely to be a lubrication hole. I cannot imagine it would have a grubscrew in it.

Almost 100% the spindle should be removed from the chuck end.

Is there any movement endfloat at all in the spindle?

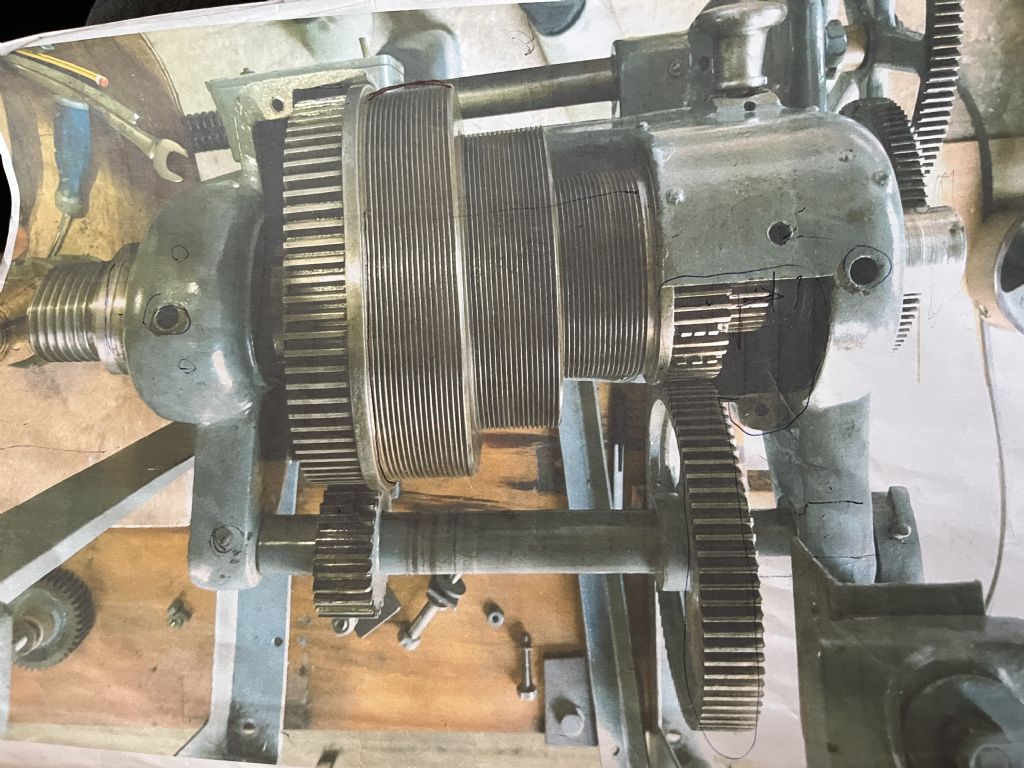

What is under the cover at the right hand end of the spindle?

Does the pulley revolve freely relative to the spindle?

A picture showing more of the headstock arrangement (not a close up) might help.

Ian P

Just noticed there are two hols in the last picture, one being in the bull wheel. More likely a pin than a grubscrew if its in the bull wheel as it has to transmit a lot of torque.

Edited By Ian P on 26/07/2023 11:33:10

Aston Manning.