Of the GSD5 variants, only the GSD5-240-10N4-V looks to have a Jumper, so probably not that. I can't see any indication in the manual that 120/240vac isn't automatic.

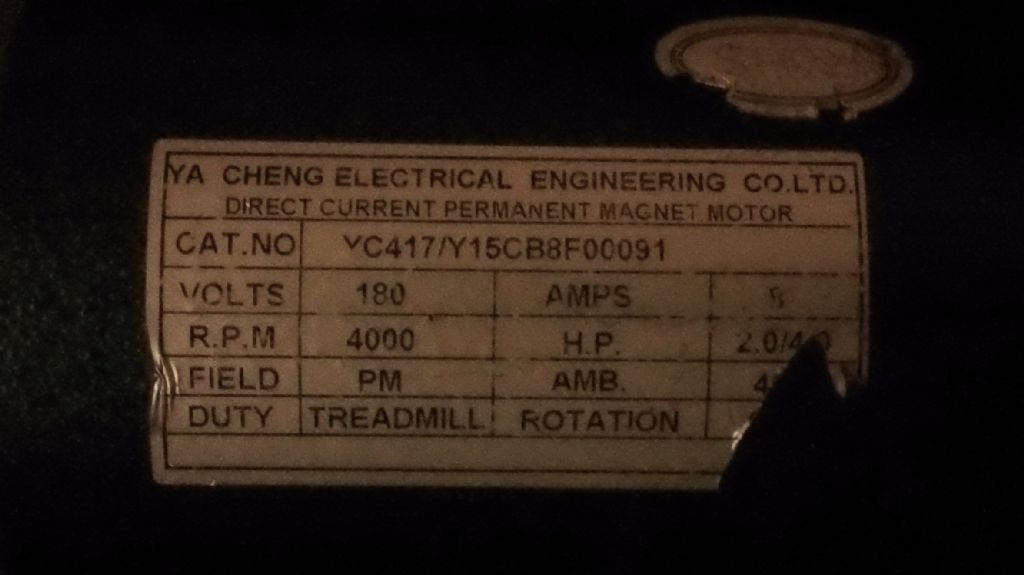

I fear Peter Cook is right, and the Treadmill motor is damaged with a shorted Armature winding. It explains the lumpy running and the fuse blowing and the controller working OK on another motor.

The Manual says:

Fusing

The GSD5 has an internal fuse in AC line 1 (P1-11), and this fuse is sized to open in the event of a shorted armature or if an armature line is shorted to earth ground.

Sorry, but my money is on the motor being faulty. Running rough and blowing fuses is highly suggestive of a shorted armature. Can be tested as Peter described by measuring the resistance of the motor whilst turning the axle. A £10 multimeter as sold by most car factors or Amazon will do the job.

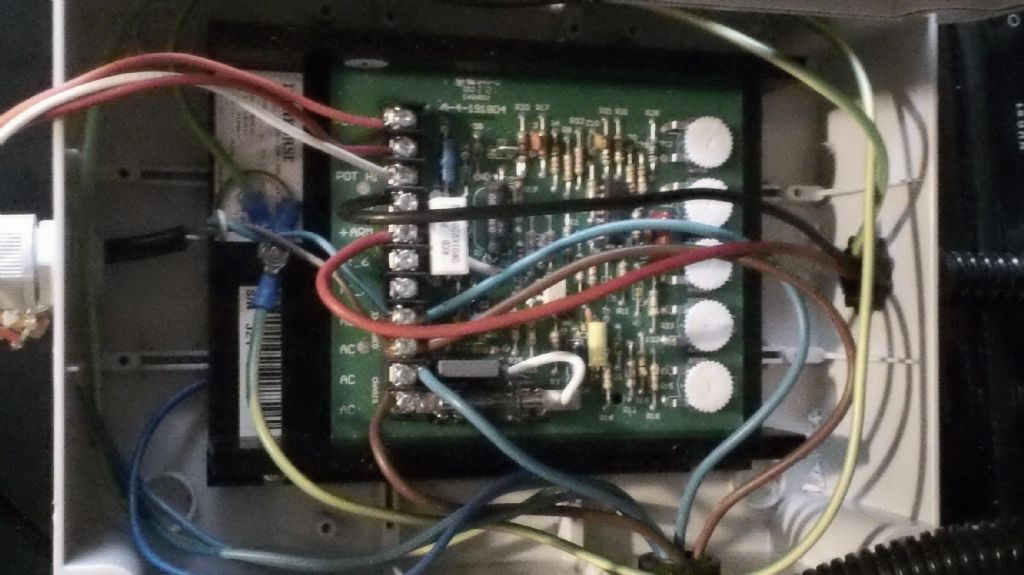

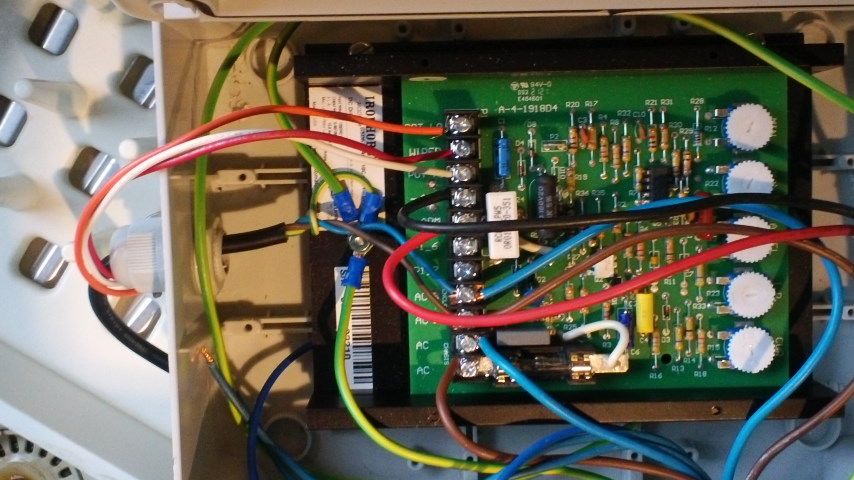

However, can you post photographs of the wiring? Connections to the motor, controller terminals, etc. Be good to find from a photo that it's not a faulty motor.

The motor is 2HP. That isn't a fixed upper limit, it's how much power the motor can deliver without overheating. As it's OK to overload electric motors in short bursts, the 4HP is probably the maximum burst output. It's allowed for a few seconds provided the motor is allowed plenty of time to cool off after. When an electric motor is overloaded for too long the windings get hot enough to damage their insulation, and the motor shorts out. Once magic smoke emerges the windings are scrap. Usually cheaper to replace a small motor than have it rewound.

Dave

Andrew Cressey.