Morning Gentlemen,

I'm John DeArmond, Chief Engineer at Fluxeon.com, a company that manufactures induction heaters.

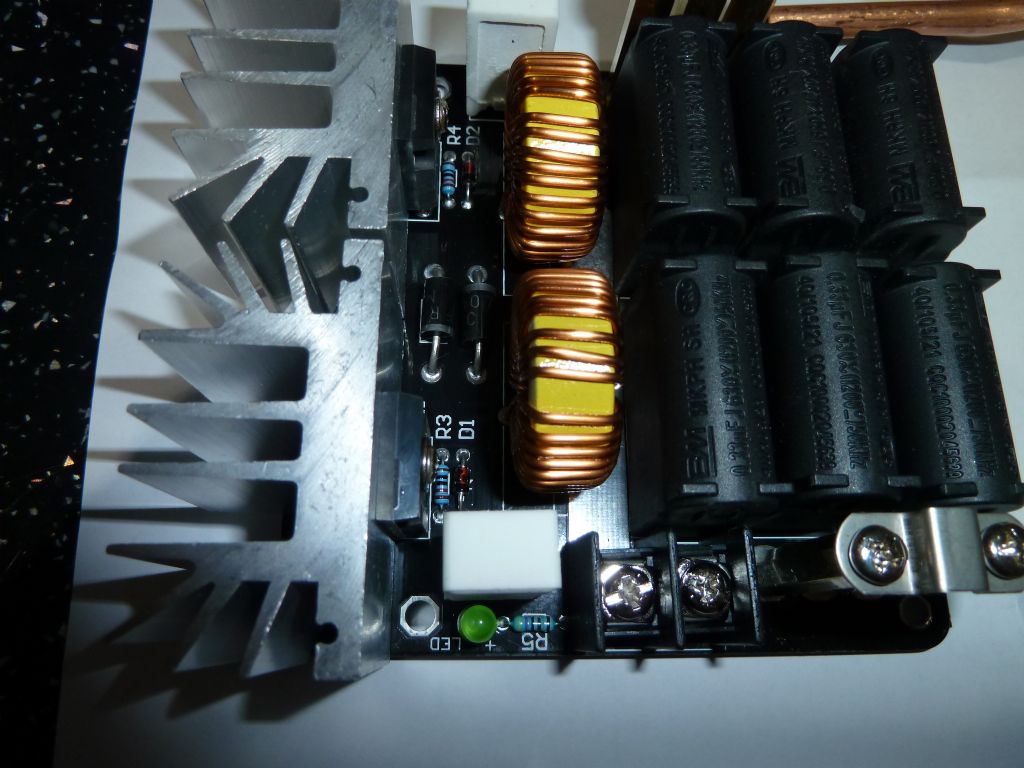

I have one of these heaters. We buy such heaters to do competitive analyses on. It turned out to be what I thought – a knockoff of one of my very earliest open source designs from back when induction heating was a hobby.

It works – sorta. It requires an odd voltage and current that not many folks have around. Something like 50 volts at 20 amps. The reason that the voltage is odd is that it derives gate drive for the FETs directly from the source of the opposite side. By the time the voltage reaches about 50 volts, the dropping resistor to get the gate voltage down to the required 15 volts is high enough that the switching becomes slow enough to overheat and burn out the transistors.

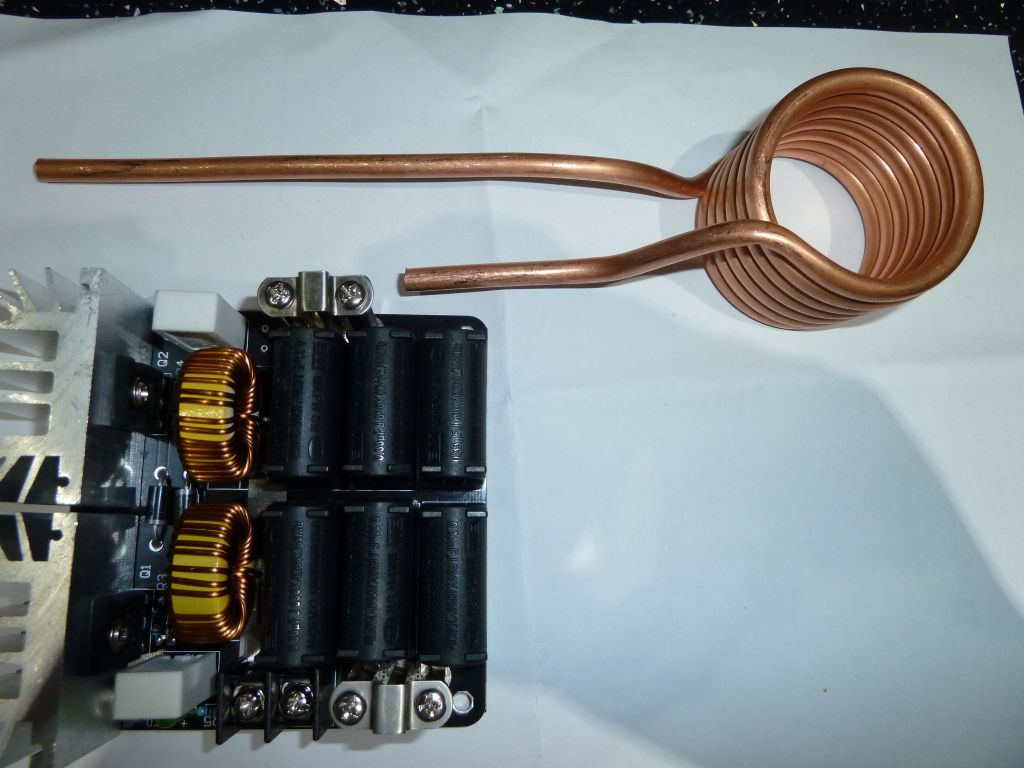

The other main problem is that the coil is at the DC supply voltage. No, the coils do not touch. That is a superbly made work coil, probably the best part of the unit.

That design taught me that I had to separate gate drive from the coil voltage. This is the resulting design.

http://www.neon-john.com/Induction/Roy/Roy.htm

This design separates the switching and the gate drive and prevents simultaneous gate turn-on by using a simple flip-flop. This unit will run from US mains voltage (120). because the voltage appearing across the IGBT collectors is 3X the DC supply, I haven't yet found an affordable transistor to work at 230 volts.

This page is a bit outdated but I'll be doing a revision real soon now  Our current main product, the Roy portable induction heater uses this basic architecture. I found a faster transistor so it can run at higher frequencies and my gate driver includes integral desaturation protection and Miller clamping. The next revision of the open source unit will reflect these changes.

Our current main product, the Roy portable induction heater uses this basic architecture. I found a faster transistor so it can run at higher frequencies and my gate driver includes integral desaturation protection and Miller clamping. The next revision of the open source unit will reflect these changes.

Officially our most powerful heater is 3kW. On the bench I have one running at 6kW, the only change being better heat sinking and a larger transformer. I use an output transformer for life safety considerations.

IF you want to experiment with induction heating, the transformer-coupled Royer is the easiest and least expensive way to go.

John

Edited By Neil Wyatt on 25/11/2015 17:13:16

Anonymous.

Our current main product, the Roy portable induction heater uses this basic architecture. I found a faster transistor so it can run at higher frequencies and my gate driver includes integral desaturation protection and Miller clamping. The next revision of the open source unit will reflect these changes.

Our current main product, the Roy portable induction heater uses this basic architecture. I found a faster transistor so it can run at higher frequencies and my gate driver includes integral desaturation protection and Miller clamping. The next revision of the open source unit will reflect these changes.