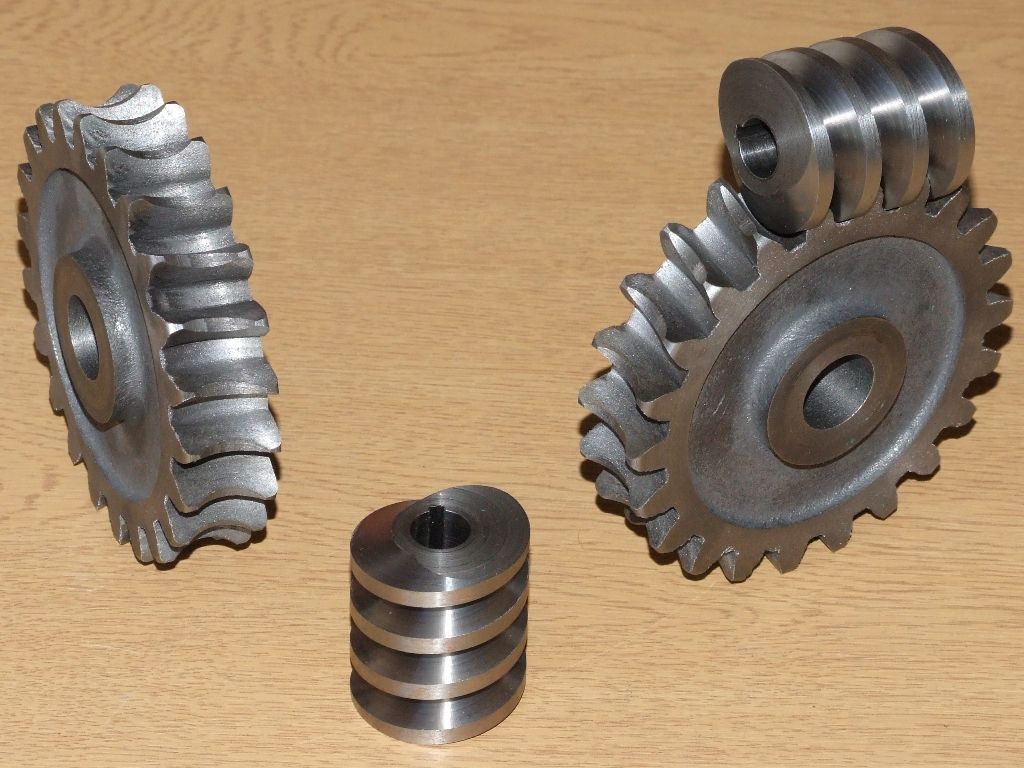

Yesterday, while the CNC mill was whirring away cutting the teeth on a bevel gear, I gashed and free hobbed the real worm wheels for my traction engine steering gear. To save space I haven't posted pictures of the gashing and hobbing processes, as they're not much different to the earlier tests; minus the coolant though as the real parts are cast iron. Here are the machined worms and worm wheels:

I made a few changes from the procedure used to make the test worm wheel. When gashing I didn't cut quite so deep, 9mm instead of 9.5mm, the idea being that the hob would give a better looking result if it had to remove a little more from the bottom of the tooth spaces. I also took more care to centralise the hob before cutting. The main change was after hobbing to full depth; I upp'd the spindle speed, to 117rpm, and wound the cross axis over about 1/2" in small steps in an attempt to get rid of the faceting on the worm wheel teeth due to the straight flutes on the hob. Here's a close up of the worm wheel teeth, warts and all:

The picture was taken straight after machining, I need to do a bit of deburring and cleaning up. The finish isn't quite as bad as the picture suggests, but importantly the faceting seen on the test worm wheel has disappeared.

The parts are not perfect  , but I've learnt a lot, had some fun, and it's now time to move onto other items.

, but I've learnt a lot, had some fun, and it's now time to move onto other items.

Regards,

Andrew