There's always something to trip you up…

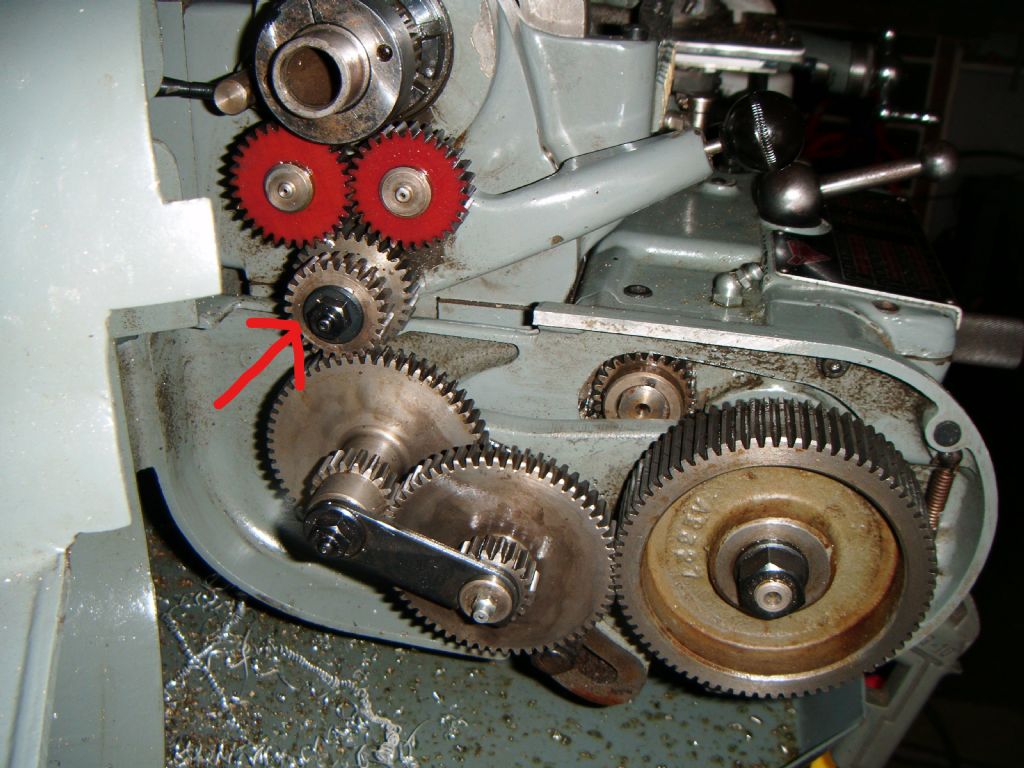

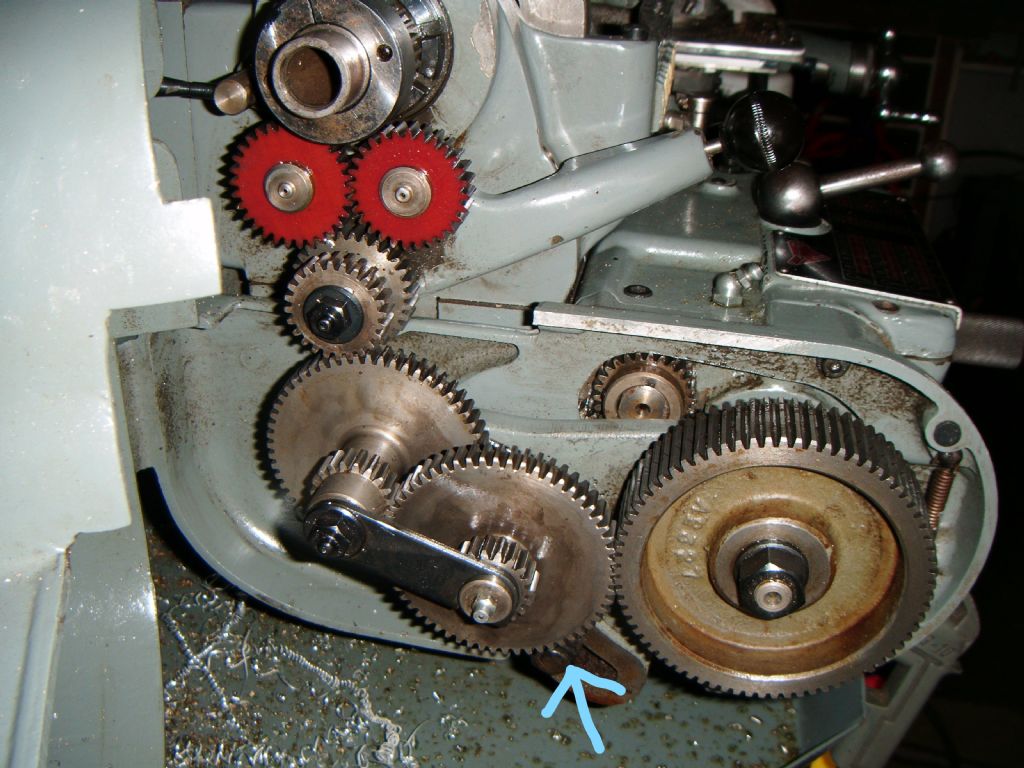

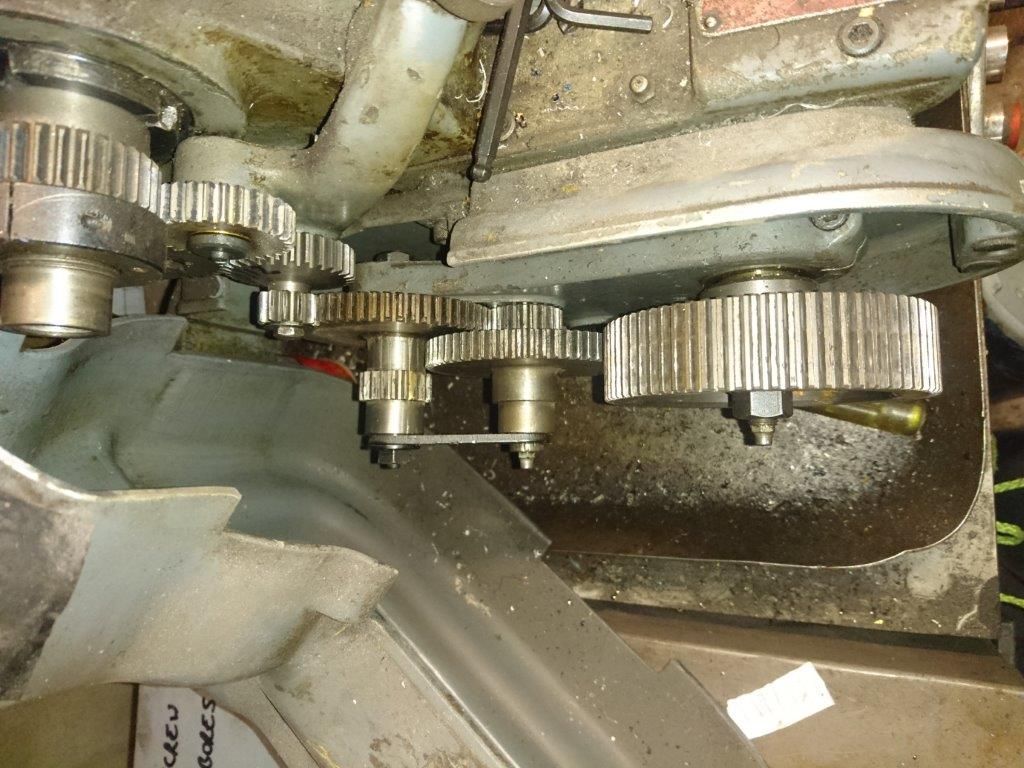

I've spent a while over the last few days making a 33 and a 34 T gear, also a 24 and a 26. Gone to play with cutting metric threads with then this morning, and fallen foul of the fact that the gear A on my S7 is a 30/12 couple. Uh?

Of course the answer in in the archive. I quote (from a thread dated 27.2.2012 called "Myford Quick Change Gearbox":-

Mike,

You are not getting the full story. So before you get in too deep……

In no particular order:

1. The last gearbox of the type you have was Serial No. QC (for Quick Change) 2500. QC2501 was the first "modern" one.

2. It is thought that many early gearboxes were retrofitted in the factory with hardened cogs, but no records were kept. Also quite possibly from some point before QC1950, hardened cogs were fitted as standard.

3. The leadscrew on your none-gearboxed machine has quite probably got a different plain diameter at the headstock end, as in smaller than what you require.

It must fit the hole in the gearbox casting closely for obvious reasons.

4. It is somewhat trickier to align the gearbox with the leadscrew, but it must be done and done carefully or the hole in the casting for the leadscrew becomes worn. The "modern" box is almost self aligning as it goes right through, but it still needs doing.

5. To align the gearbox properly, you need a spacer strip between the gearbox and the top two fixing screws along the bed shear. It is just a flat strip with two holes in, but I have no idea what the thickness is. That is a left over from the earlier ML7 fitting.

6. Your gearbox runs at half the speed of the "modern box" to cut the same thread. That is to say, your output gearing at the right hand end is 1:1, whereas the modern box is 2:1 at the left hand end. There is no chance of you altering the principle to be the same as a modern one as you won't make it fit!

7. A consequence of this that you also need a 12/30T FINE FEED TUMBLER GEAR A1974A/1 as it is termed on the Myford/RDG website to drive the standard fixed quadrant geartrain. The modern box uses 24T/30T and hence does not have to be a combo cog.

8. Do not try and use the Myford modern screw cutting details as in a later manual as you will end up with a times 2 factor as above, but you can do far better none imperial threads than the earlier Myford tables.

9. The guts of the boxes are identical and interchangeable apart from the shaft differences of course

Think that's it.

You have some way to go to get going.

Dennis

And I do indeed have the older gearbox on a S7 of the same vintage.

So, I have discovered that the banjo won't drop far enough to allow me to fit my new 33 and 34 gears, I'll have to modify the banjo slot to do so. Is this opening another can of worms?

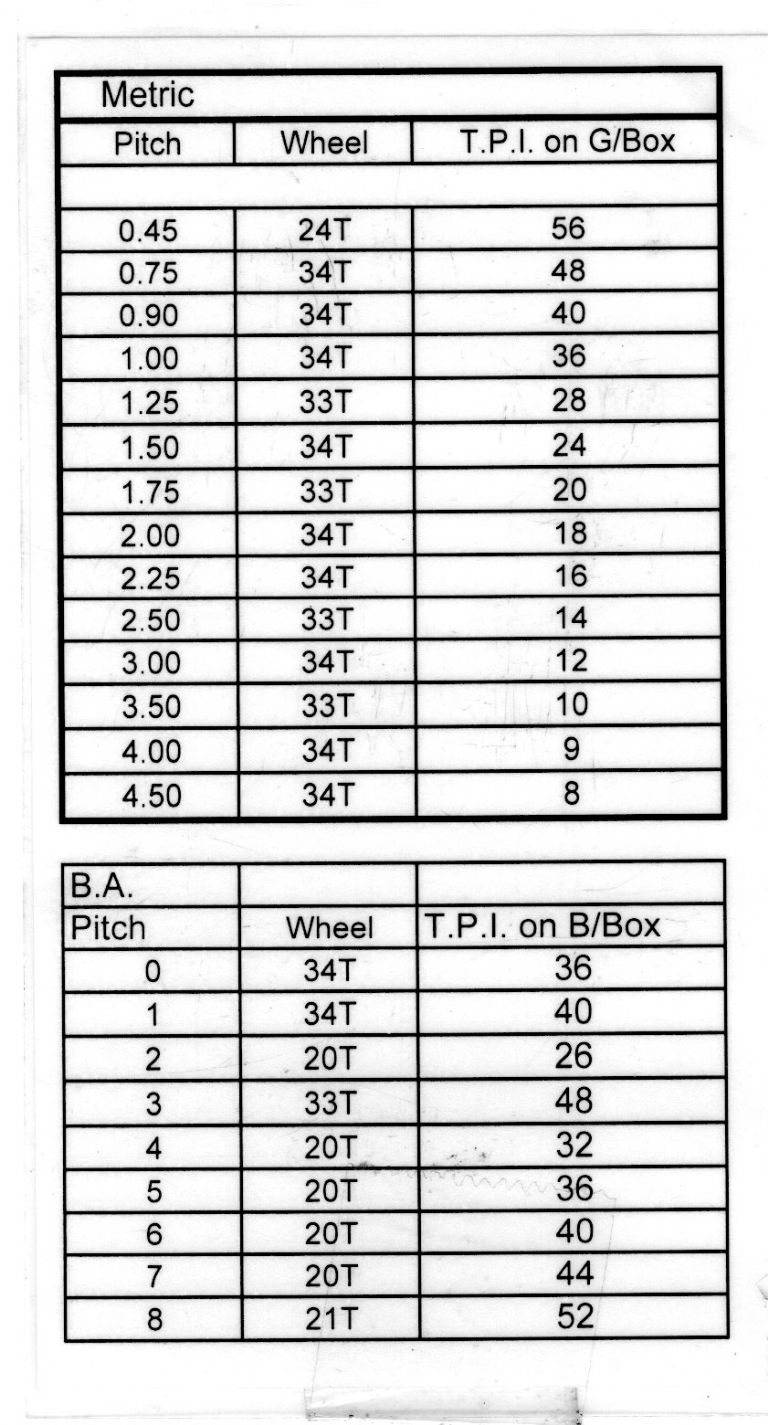

Having got the gears to mesh, I can in principle adjust the top lever and side lever selections to choose half the TPI the table above indicates, as my gearbox will be running at twice speed. I've yet to think this through, but I doubt I'm the first – does this work?

Rgds as ever to all, and thanks for the help.

Simon

edited to remove a yellow winky face I didn't ask for….

Edited By Simon Williams 3 on 18/03/2017 13:08:11

Steviegtr.

Steviegtr.