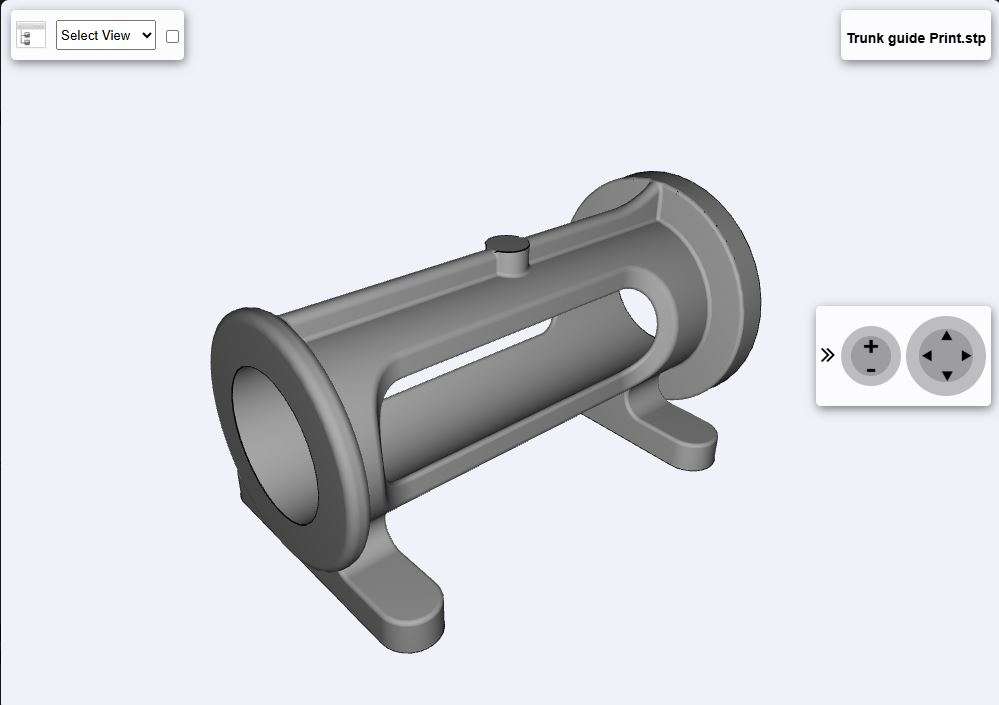

I’ve been waiting a while for a suitable part to come up that I could get 3D metal printed just to see how it would turn out. The trunk guide for my next engine seemed to fit the bill so an STL file was created from my Alibre 3D CAD model and uploaded to a few online printing sites to see what the costings and options were.

I have seen mention of Craftcloud on a couple of other ME forums and ended up going with them. Stainless Steel 316L along with Aluminium seem to be the most common and cost effective materials and Craftcloud offer several prices for both, they also offer DMLS which is said to have smaller layer height than SLM which most other sites do so I went with a 316L DMLS part, basic sandblasted finish.

Production was quoted as 3-4 days and a further 3 for delivery and that is what it took. Several update emails to tell me of progress and good tracking all the way via Fedex.

I’m quite happy with how it turned out, better than most sand castings and as good as many lost wax. There was a tiny depression on the flange but as I had allowed 1mm machining allowance on that, the feet and the bore it was not an issue. I can’t see any layer lines and there is just a hint of a bit of remaining support in a couple of places. For an idea of scale it is 61mm long.

Milling (carbide) and boring (HSS) were fine, just a bit more pressure needed when drilling the holes (HSS) so no problems with machining which some of the earlier sintered 3D prints gave problems with.

Cost wise it was a bit expensive compared with what I could have fabricated it for or even cut from solid on the CNC. It was a fairly even split between the minimum job cost and postage costing just over £50. However having later looked at the Fedex shipping that postage cost would have covered anything upto 1kg and I could have got more prints done and still been within the minimum so could actually have gotten seven printed for the same cost bringing the individual cost to about £7.50. If using again I would group a few parts together so that they were all covered by the one off job cost as that would be far more economical.

M-Machine have just delivered the other “raw castings” so can you guess what it is yet?

jimmy b.

jimmy b.