We have received payment for the content in this article. Learn more.

Anime and manga trendy play – hand puppets

Part size: 219178145mm

Introduction: As a high-end consumer product, the anime doll has always received the majority of anime fans, in addition to IP licensing fees and limited nature, a large number of manual processing processes make the manufacturing costs of the doll remain high. 3D printing’s high degree of restoration and high detail can allow the artist’s creativity to be quickly realized at the same time, but also to meet the demand for limited edition goods. PCBWay provides long-term and stable services for many IP manufacturers and design studios, exploring and summarizing the production process standards in line with the anime hand-me-down industry, with hand-painting and hand-painting coloring technology, gradually reaching consumer-grade tactile requirements in terms of detail display.

Material selection: Uf-S3000, Uf-H130, red wax

Process points: hand-painted hand-painted coloring

Industrial Electronics – Router Housing

Part size: 10010022mm

Introduction: A large e-commerce platform customized products, the precision of each batch of products, material performance and other high consistency requirements, requiring the overall shell can be formed in one go, each snap tightly. Its toughness and strength can meet the natural fall from 1-1.5 meters without breaking. Fiber optic jack part not only requires accurate opening accuracy, but also must have excellent toughness and strength, and the fiber optic connector can be stuck stably and not broken when inserted.

Delivery time: 24 hours

Material selection: Uf-S3100, Somos® Ledo, Somos® Taurus

Process points: External coating process Internal support structure design High performance material process

Medical Applications – Orthodontics

Part size: 98.24911.5mm

Introduction: Made by DLP industrial equipment, the molding accuracy can reach 0.02mm. using the latest intraoral scanning equipment to accurately obtain the patient’s intraoral data, which is more accurate than traditional impressions and plaster molds, facilitating medical personnel to develop suitable medical solutions. UCLI keeps cooperation with first-line dental institutes and technical institutes, 5 minutes docking, 2 hours production, each product is provided with scanning and testing report, same day delivery in the same city, S.F. express delivery in different places.

Delivery time: 2 days

Material selection: Uf-H130, Uf-S3100

Process points: precision tuning process batching testing capability

Precision casting – Aviation magazine

Part size: 683498466mm

Introduction: 3D printing process in the field of investment casting has the advantages of high molding accuracy, free modeling, fast delivery cycle, low cost, less material waste, safety and environmental protection.

Delivery time: 4 days

Material selection: Somos® 11122, Somos® Element, Uf-Casting

Process points: High precision process, wall thickness parameters, internal topology, splicing process

Sculpture beauty – Dragon sculpture

Part size: 1936498576mm

Introduction: Printed by 2m1 large SLA equipment integrated printing molding, no splicing detail performance excellent. Compared with the traditional production of clay mold, wooden mold, greatly save the production time, high detail reproduction, a molding. Combined with the high hardness material, it can meet the strength requirements of all kinds of surface post-treatment and mould turning and demoulding at a later stage. Since its establishment, UCLI has cooperated with major domestic sculpture enterprises and a large number of design studios to meet their various needs such as design verification, mold turning and final part production.

Delivery time: 6 days

Material selection: Uf-H130, Uf-S3100

Process points: Large size printing process External coating process Internal support structure design

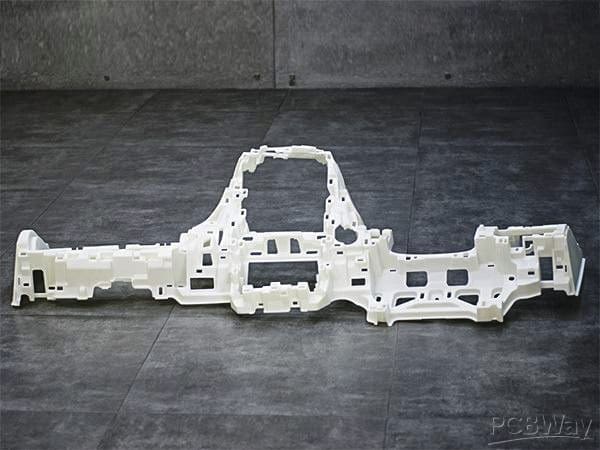

Automotive Manufacturing – Automotive Instrument Panel

Part size: 1632638576mm

Introduction: Printed in one piece by 1m8 large SLA equipment, no splicing, no scaling, the original assembly test and wind tunnel test of the real car were carried out, the parts are precisely sized, fitted together, the holes correspond one to another, and various structural and functional tests were completed in the water. PCBWay and domestic mainstream OEMs and OEMs maintain a year-round relationship, PCBWay has been in the hand board, modification, work tools, engineering plastic parts and other application scenarios for the automotive industry to provide tens of thousands of parts.

Material selection: Somos® Ledo, Somos® Taurus, Uf-H130, Uf-T8200

Process Highlights: Dimensional accuracy process High performance material process Large size printing process

Architectural sand table – Micro home sand table

Part size: Splicing

Introduction: The micro home sandbox has a total of 3926 parts, 90% using 3D printing technology, the whole production process took 6 days, including 6 sets of model homes overall home decoration display, including lighting, liquid nitrogen and other special devices. The use of 3D printing technology can quickly obtain a scaled architectural model with complete replication of details and smooth and fine surfaces to assist designers in perfecting their initial design plans. The produced model can be easily displayed to customers, and the surface of the model can be painted and colored, and the interior can be installed with lamps, liquid nitrogen and other facilities according to the actual design needs.

Material selection: Uf-H130, Uf-S3100

Process points: external coloring process, internal display facilities internal support structure

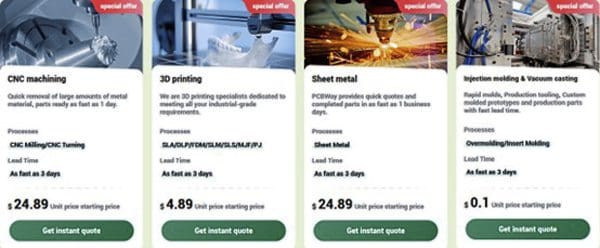

How can you order CNC or 3D printing services?

Ordering CNC or 3D printing services has never been easier! PCBWay makes a wide range of industrial-grade prototyping services accessible to everyone. For CNC services, you can select from various materials and finishes to meet your project requirements. Simply visit their website, where you can easily upload your design files and choose your preferred service with just a few clicks. The user-friendly interface allows you to specify parameters such as material type, thickness, and tolerances for CNC machining. If you’re looking for 3D printing services, go to the quote form, select the necessary parameters, and upload your CAD files. You can choose from a variety of printing materials and technologies, ensuring that your prototypes meet your specific needs. This is a fantastic opportunity to take advantage of their excellent services at a lower cost. Whether you’re working on a small project or a larger production run, PCBWay is here to help you bring your ideas to life with their CNC and 3D printing solutions.