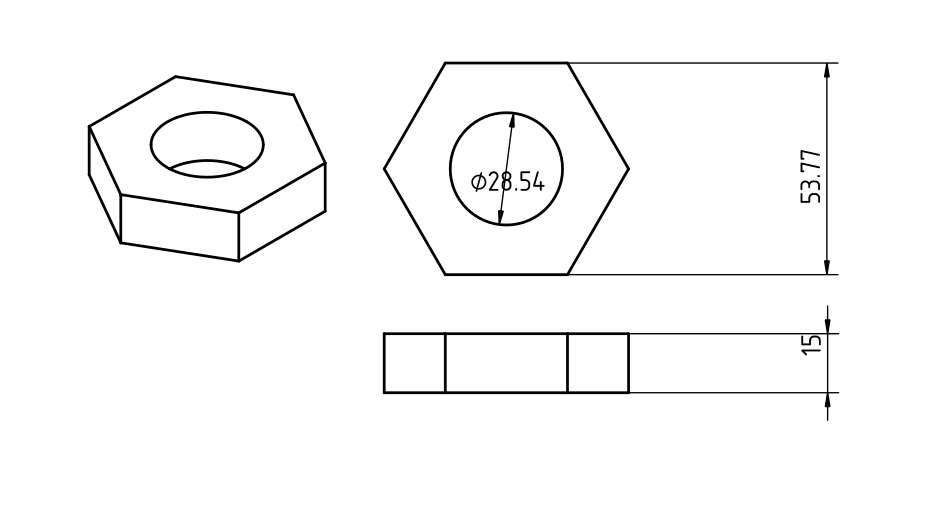

If the nut shown is 1/2″ M E, that is a BIG Compass. Presumably for a sea going merchantman?

Is it intended to act as a locknut, to introduce friction, so that the compass, once inclined, stays at that angle?

Model Engineer threads are Whitworth form, so there should be a little rounding. This will make the bolt thread OD a little less than 1/2″. by 0.16P, or 0.005″, to give an OD of 0.495″

According to Tubak Cain’s “Model Engineer’s Handbook”, the standard pitch for a 1/2″ Model Engineer thread is 32 tpi; so these are “special” at 40 tpi.

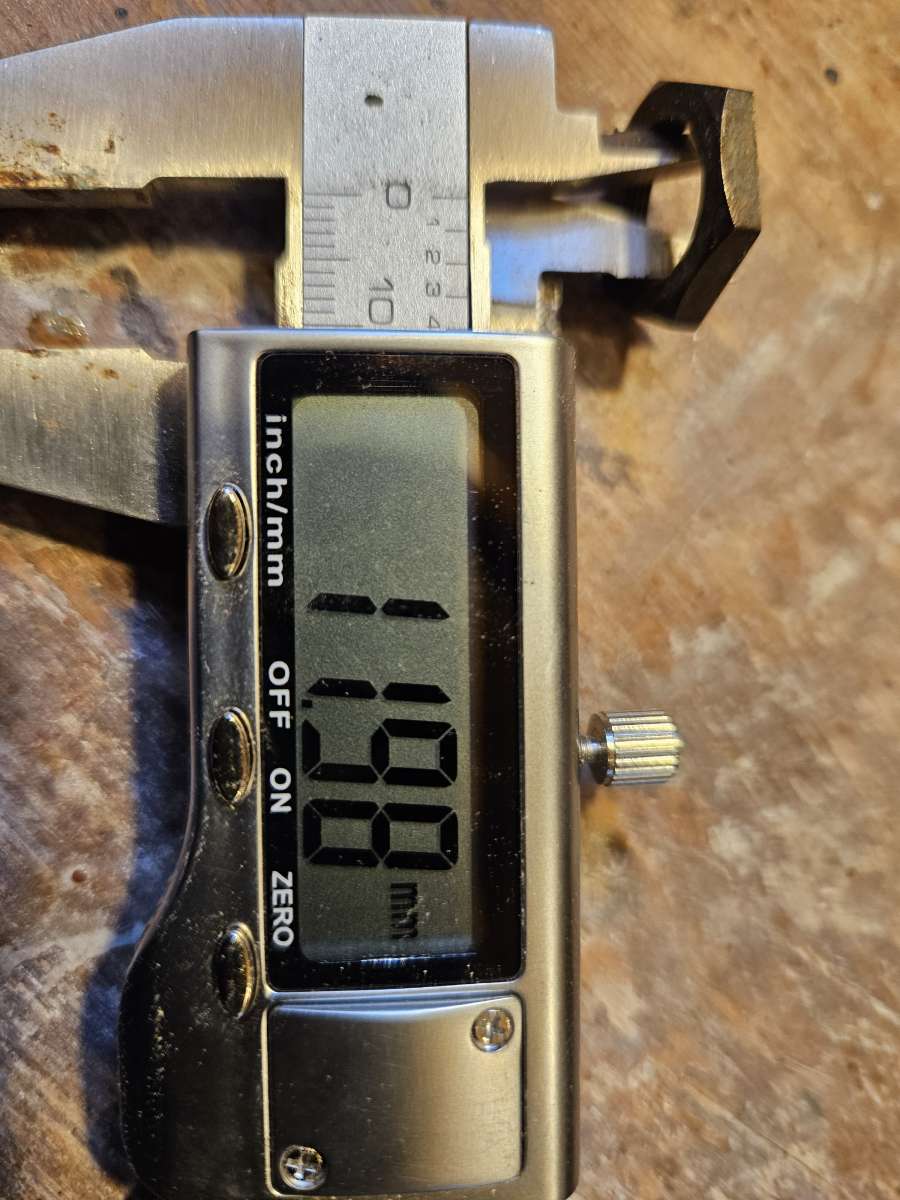

The depth of 40 tpi M E thread is 0.016″, so theoretucally the Tapping Drill should be 31/32″ (12.192 mm) The nut is likely to have a measurement over the rounded crests of 0.473″, so a 12.2mm drill should isuffice

Without wishing to be rude, it is posible that the OP lacks the facilities, if mot the skill, to make the required nut, and is indirectly asking if someone will make it for him.

But more information is required, as to the thickness of the mut; AND what size hexagon does he want? The standard for a 1/2 BSW or BSF hexagon should be 0.820″ ACROSS FLATS, although with a shallower thread this could be reduced.

And, where is he located? Shipping a nut to the antipodes , or to somewhere in Asia, might be an expensive and complicated procedure.

For a marine environment, steel is not likely to be the best material, unless stainless (which may bring its own manufacturing problems) rather brass or even phosphor bronze.

Howard

Nealeb.