If I’m clamping something down direct to the table I give her a scientifically judged bit of welly – actually I’m quite careful not to distort it, (by using a cut down spanner) and only 3 points of contact.

But my point was that if you are using sheet metal covers, and as was intimated, one might be clamping onto such a thing, then to get a vice to sit flat to engineering limits, yes you’d have to use a torque wrench, since all things are elastic. That is something that is a bit overmuch trouble for me.

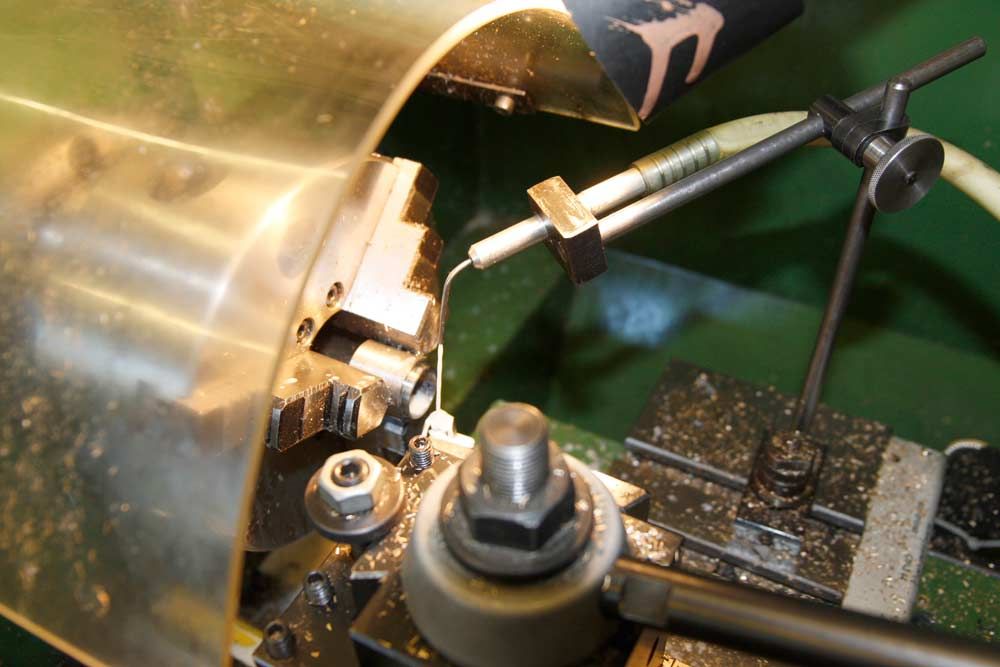

I’m not against covers – most of my kit is covered when not in use – and I have some ply thingys to put on the lathe bed when changing chucks to make sure the bed doesn’t get damaged. I made sure I spent a fair bit of time an dosh coverng DRO scales. But with the greatest respect to those who feel covers are useful on a milling table – damned if I can see it.

Sheet over the machine at the end of the day – sure. But to leave plates on the bed, under which some coolant will sit, ready to promote bacteriological staining , or to try to keep swarf out of slots which will collect some anyway?

Not for me.

Mowever, I like the magnet/polycarbonate idea for a vertical splash screen Using tips under a good coolant flow, with 2″ facing cutters the overspray can be a bit broad!!!

duncan webster 1.

, but thick brown “Kraft” paper makes an excellent mill table cover. It can go under the vice quite easily and will cover the tee slots effectively. One big advantage, at this time of year, is that by soaking the paper in oil, rust can be kept to a minimum. Another advantage over a tin tray , on smaller mills, is that paper is not rigid and will not get in the way at all.

, but thick brown “Kraft” paper makes an excellent mill table cover. It can go under the vice quite easily and will cover the tee slots effectively. One big advantage, at this time of year, is that by soaking the paper in oil, rust can be kept to a minimum. Another advantage over a tin tray , on smaller mills, is that paper is not rigid and will not get in the way at all. Sorry Mr “C” , but I could not resist a slight, but good humoured dig.

Sorry Mr “C” , but I could not resist a slight, but good humoured dig.