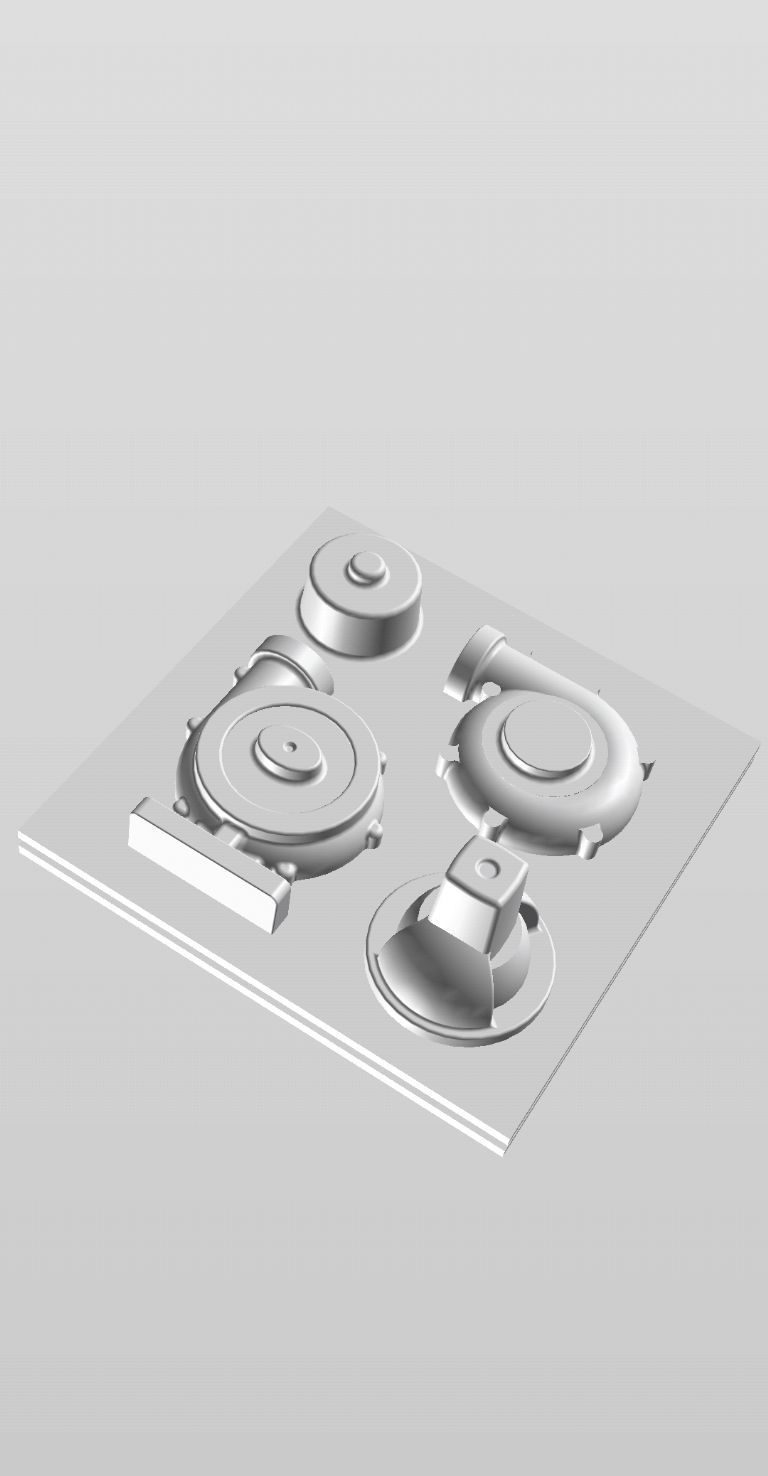

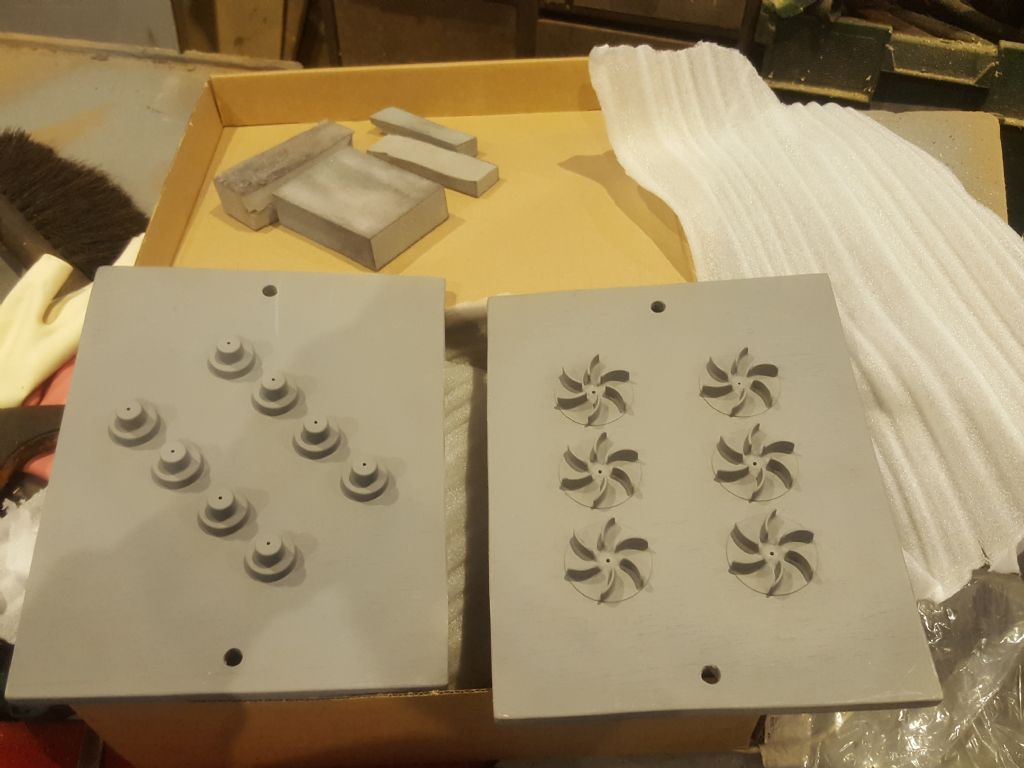

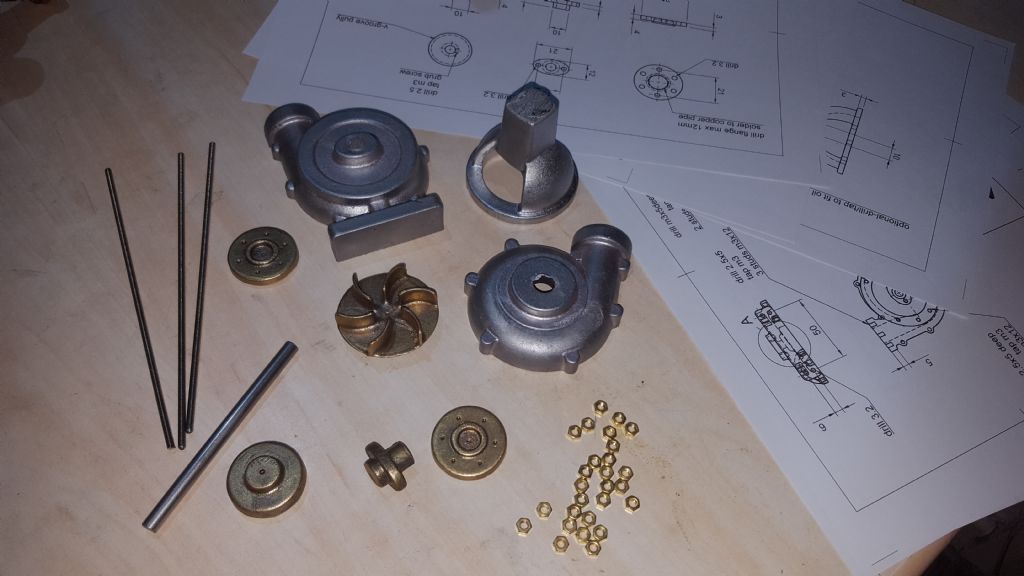

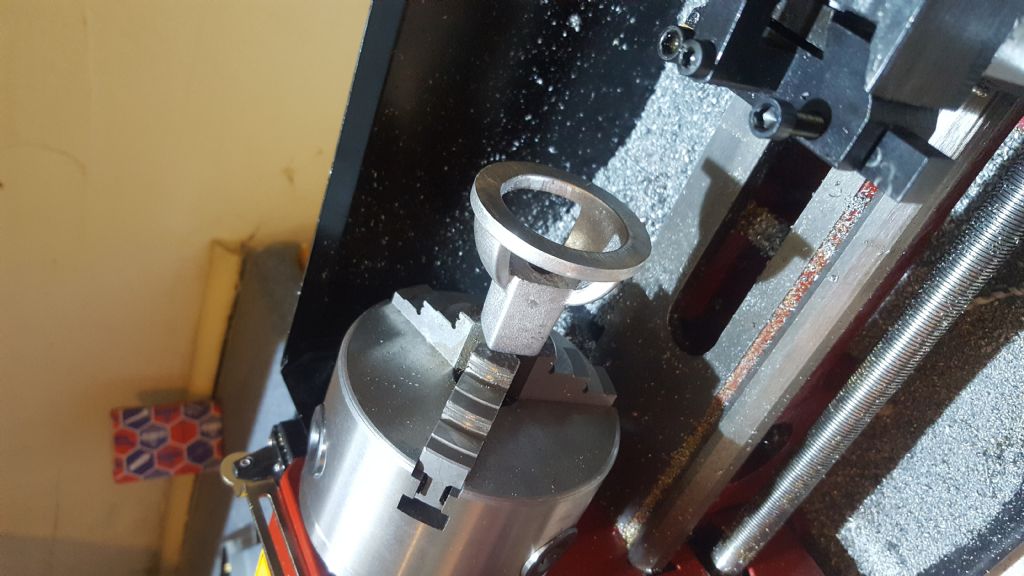

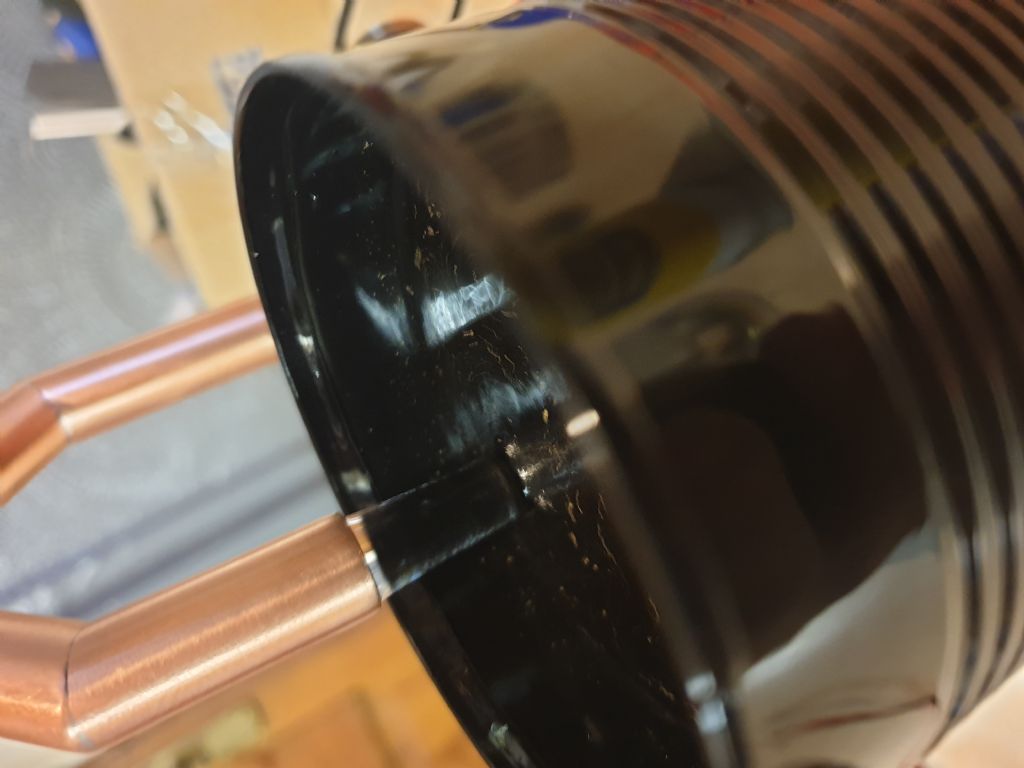

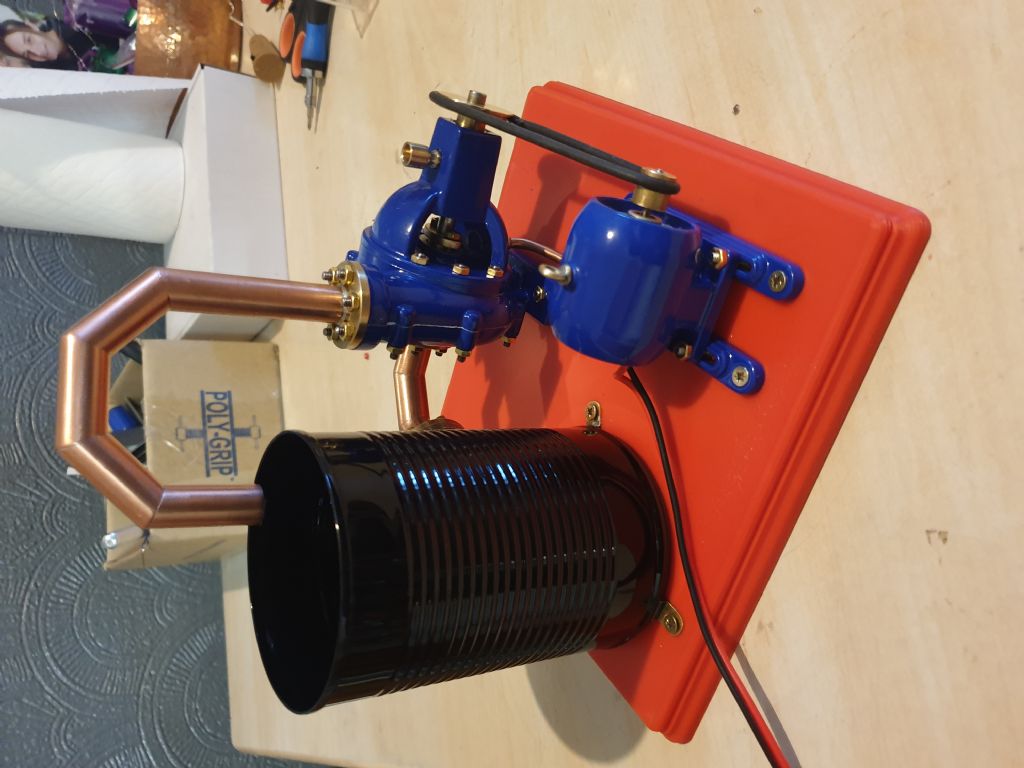

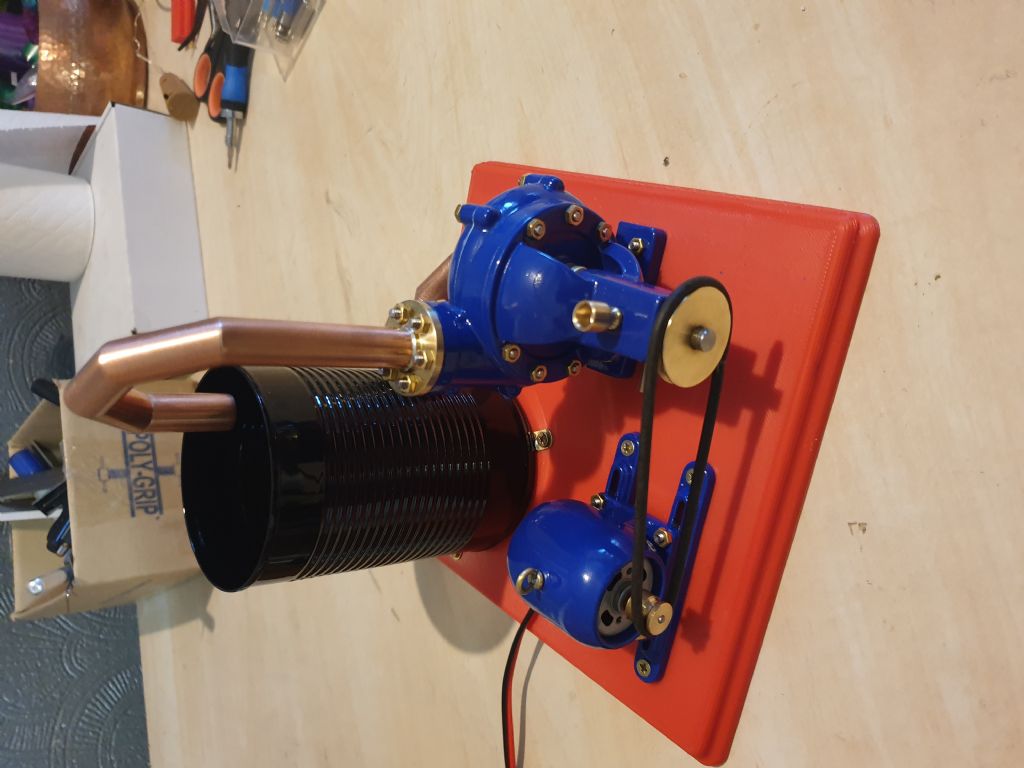

Centfugal pump build

Centfugal pump build

- This topic has 16 replies, 1 voice, and was last updated 13 May 2019 at 19:52 by

Cringle,model,engineering.

Viewing 17 posts - 1 through 17 (of 17 total)

Viewing 17 posts - 1 through 17 (of 17 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Which type of single phase motors are best for constant use – power hacksaw

- Stripped aluminum threads. Now what?

- Problem getting the right parameters on a VFD

- Supply company catalogues

- Flattening brass plates

- Damp proofing concrete floors

- Machinery Handbook

- Chester DB10LB Lathe – Not starting

- Measuring increments on boring head

- Elliott Omnimill Quill Clamp