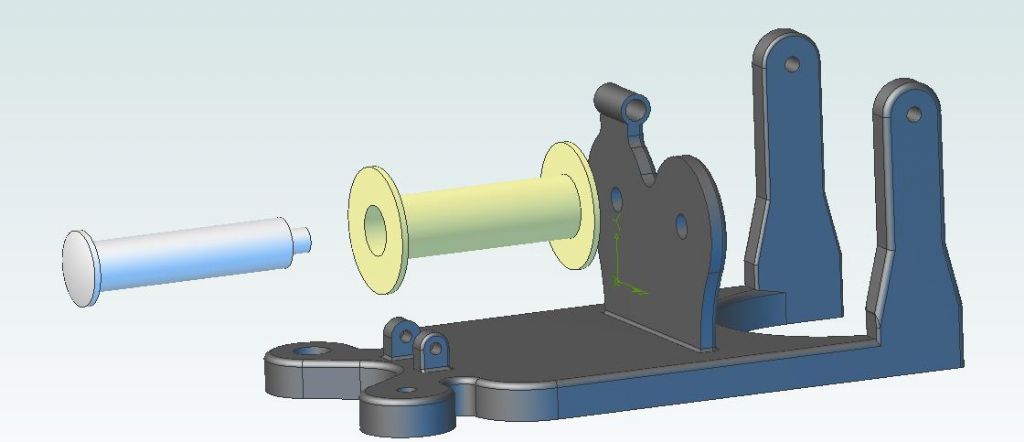

Isn't making the core more difficult than authentic looking wire?

Motor cores were first made of soft iron, but soon switched to Silicon Steel. To reduce eddy losses the core should be laminated, which is usually done by stamping because Silicon Steel is hard to machine. You could probably get round that problem except Silicon Steel sheet doesn't seem to be sold in small quantities – minimum order 5 metric tons! Nor is soft iron easy to find. The laminations out of a transformer are the wrong shape, and reusing an existing motor core is, well, just a rewind, not a model.

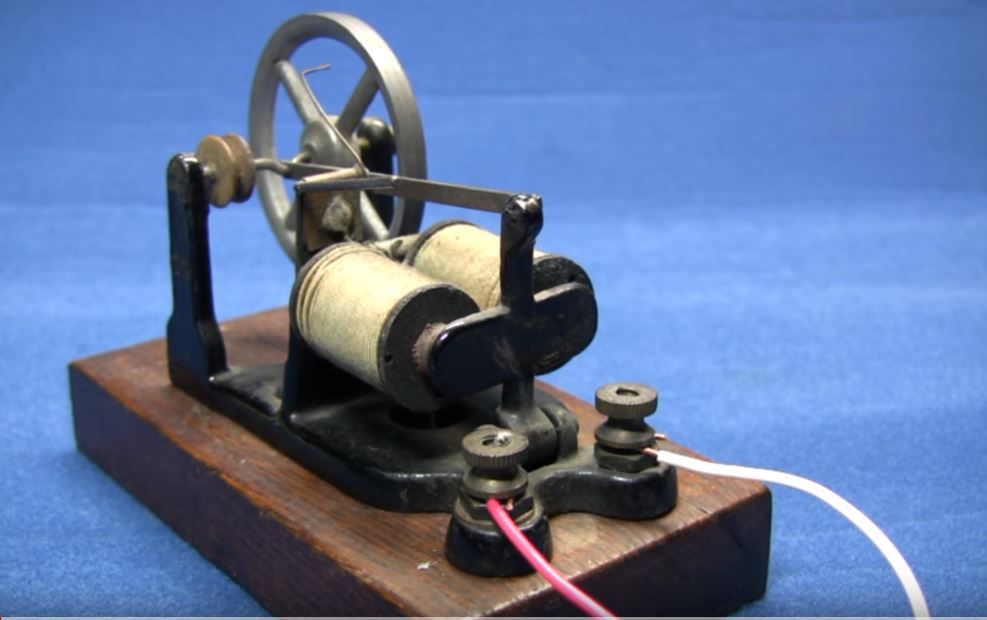

On the subject of producing authentic cotton or silk insulated wire, a braiding machine would make an interesting model too. I've often thought it strange that model engineers tend to concentrate on engines when spinning, weaving, printers, Pascal calculators, Enigma machines and many other mechanical marvels are equally rewarding.

Dave

Edited By SillyOldDuffer on 07/11/2018 18:12:13

JasonB.

JasonB.