Graham,

Welcome to the Forum.

Yes, ask questions and answers will soon appear. IF folk understand what you are asking.

What do you mean by the "Primary gear"?

If the lathe has back gear, under normal circumstances the drive pulley is secured to the Bull wheel in some way.e (On the big sister, ML 7, IF I remember from 20 years ago, there is a "key" which locks the pulley to the Bull wheel (The big gear not far behind the chuck ). The capscew is slackened and the "key" can then slide to and fro, radially to lock the Pulley to the Bull wheel, or to disengage it..

If back gear is to be used, the "key" needs to be moved inwards, to disengage the pulley from the Bull wheel.so that when Back gear is engaged you are not trying to drive the spindle at two different speeds mat the same time. If you do, everything locks up!

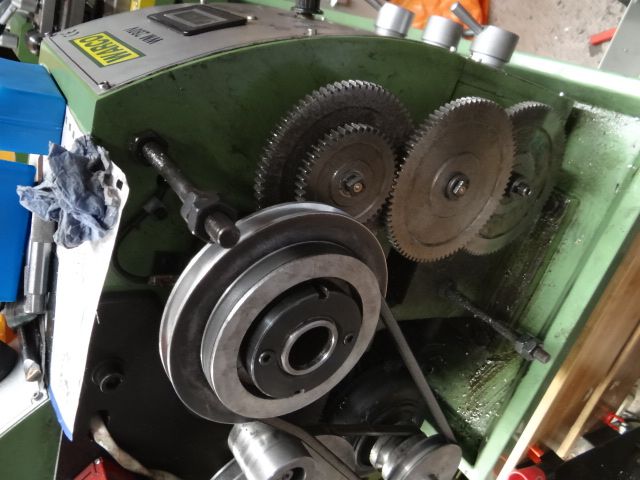

(Normally, to engage back Gear, the shaft carrying two gears,can be moved so that they mesh with a gear on the Spindle and the Bull Wheel, to provide a two stage reduction in speed.

My present lathe has a spring loaded dowel which locks the Bull wheel to the pulley so that when the Back Gear cluster is brought into mesh, the dowel is disengaged, so the drive is via the two stage reduction, This runs the Spindle at a lower speed and provides more torque. (Often about a 5 or 6 times speed reduction ).

The drive comes in via the pulley, the small gear drives the large gear on the Back Gear shaft, and the small ,gear on the shaft drives the Bull wheel which is fixed to the Spindle. .

It would be a good idea if you bought a book, such as L H Sparery, "The Amateurs Lathe", or Ian Bradley's "The Amateurs Workshop", or one of the other books on lathework.

These books answer a lot of your questions, and give a lot of other useful information, to enable you to make better use of your lathe, and avoid difficulties.

FWIW my advice is to get to know then lathe and how to use its features by making small tools, before trying to make anything complicated.

Making simple tools will allow you to gain experience, and confidence, and leave you with a few tools which will be useful for along time. come.

For a start, I would suggest making a Centre Height Gauge. This involves just simple turning, some drilling and tapping, and you will have a tool which simplifies setting tools to correct height so that they cut properly.

Then you can progress to things like Tap Wrenches, or a Tailstock Sliding Holder for Dies (This will ease cutting external threads )

There are designs for these sorts of things in books, by such people as G H Thomas, or from time to time in magazines such as Model Engineers' Workshop. If you look through Albums, you will see pictures of small tools such as these, made by various posters on this Forum.

Far better to make mistakes, you will, we all do, on a bit of mild steel, rather than an expensive casting from a kit!

Eventually, having gained more experience, confidence and skill, you might then want to make a Tailstock Sliding Tap Holder…

HTH

Howard

Edited By Howard Lewis on 10/07/2022 02:19:19

Graham Baron.