A fine find!

I concur entirely with all the advice above but will answer your question directly, as far as I can from just that photo:

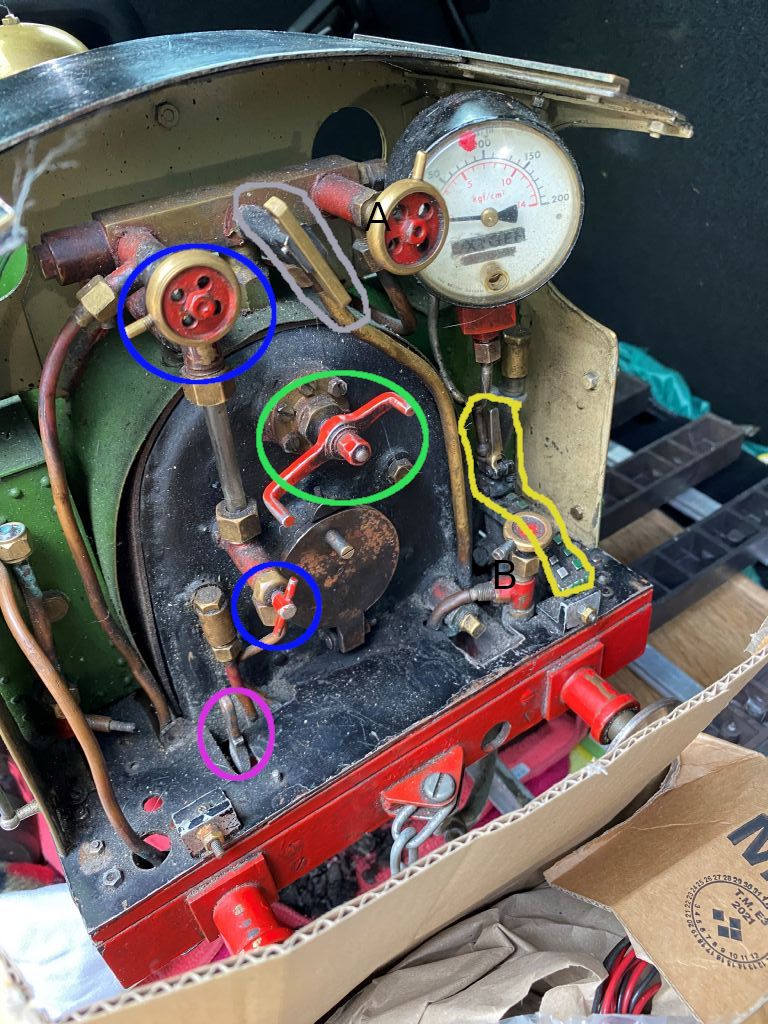

Some landmarks first –

The black-painted panel: the Backhead, the outer back-plate of the boiler, with the Fire-hole and its door. The door is normally be kept closed except when actually adding coal.

The bronze object across the top of the backhead is the Turret or Manifold, supplying steam to various fittings via the valves on it.

Touring the cab clockwise:

1) Lower left corner, possibly a valve (hand-wheel missing?), to control the boiler feed from an axle-driven pump.

2) Lwr L, on backhead: Clack or Check valve, 1-way, passing feed-water to the boiler.

2) Glass tube – the Gauge-glass shows the water level in the boiler. That level must never be allowed to drop below the visible bottom of glass when the locomotive is in steam. If the water drops too low it risks drying the top of the firebox, which can rapidly ruin the boiler and possibly risk it bursting. Most model locomotives have a means to drop the fire quickly if necessary.

Nor above the glass: a bit less serious but risks "priming", throwing water into the cylinders where it can cause damage by hydraulically locking the pistons in place. (And gives you and passengers a hot, oily, sooty shower.)

The little valve on the gauge-glass is for ensuring the gauge works, and for flushing it with a quick burst of steam.

3) Red handle in the middle: the Regulator. One of the main driving-controls, analogous to a car's accelerator but closes completely. Steam engines don't have "idling" settings.

NB: do not try to operate the regulator dry, as that can score its valve faces, especially if there is any scale on it.

4) On the manifold left to right: probably the Blower Valve, certainly the Whistle Valve (central) and probably Injector Steam Valve. I say probably because not knowing the specific engine, I am using other clues.

– Blower. A steam-jet below the base of the chimney, to draw a draught through the fire to keep it alight. When the locomotive is running steadily the blower is usually closed, as the exhaust-steam blasts induce the draught.

– Whistle. Obvious enough! The valve is spring-loaded closed.

– Injector steam. What makes me think that, for this loco, is the:

Vertical valve, RH side of the footplate. This may feed water to an Injector below the footplate on that side of the loco. The Injector resembles a connection between three pipes and a fourth open to thin air; but is a box of clever Physics using a jet of steam to push water into the boiler.

What else?

5) Pressure-gauge: the red dot is probably the required mark at which the safety-valves lift to limit the boiler's Working Pressure to specification. Good technique keeps the pressure to a touch below that red mark, as much as possible.

6) Right-hand side floor, partially obscured, lever in a notched quadrant is the Reverser – setting the travelling direction. Its intermediate settings control the steam flow into the cylinders for more economical steaming once the locomotive is moving steadily.

The Reverser has a neutral, Mid-Gear. Always park the locomotive in mid-gear when in steam, so if the regulator leaks it won't move.

8). Usually hidden below the footplate, should be a Blow-down Valve for draining and flushing the boiler; typically operated by spanner, not handwheel.

Finally, 9) the cab itself:

The two blocks at the back, and the channel in the edge of the roof (mirrored opposite) hold the cab panels removed for driving access, fitted for static exhibition.

'

As the others say, your best bet is to join a model-engineering society. Give the loco a good cleaning and see if anything looks amiss by simple engineering principles – e.g. signs of missing screws or split-pins, oddly-loose components, heavy wear. I'd expect some wear on what appears to have been a much-used engine; but do seek advice.

I'd suggest when you find a club ask if someone can go through the boiler-testing process and the loco with you, so you know what to prepare the locomotive for. If you are new to live-steam the book will seem formidable and disheartening so don't try it alone: it's not an easy read even for the experienced, although the testing itself is quite straightforwards.

You might need supply an adaptor to connect the society's test-rig to your boiler. Unless the loco came with the boiler paperwork, you might be asked to present it with the cladding (lagging) off the boiler. It is best also to know the model's design, as a recognised, published one smooths certification.

The boiler examiner will expect all working order as far as possible, but the first test is a cold hydraulic one and it will proceed to test in steam only if it passes that. A sympathetic one of the species should tell you what if anything needs attention, and even offer advice.

Examine the boiler carefully for any identifying number, though if it was home-built it probably won't, as never required in the past.

Finally, don't reveal more, but what county are you in? That may elicit local help.

Edited By Nigel Graham 2 on 06/06/2022 16:05:14

Howard Lewis.