You sound as if if you are fairly new to Model Engineering, but that you have made a superb start with the lathe.

It looks to have been well looked after, and in good condition.

If you have the manual, for the machinme, study it.

And, if you do not already have, buy a set of Zeus Charts, and some books on using a lathe, by such authors as L H Sparey, Ian Bradley, Neil Wyatt, or Harold Hall. You can learn a great deal from them

A very useful reference book is Tubal Cain's "Model Engineers Handbook"

All the above will provide useful information, often answering your questions before you need to ask them.

With regard to locking things.

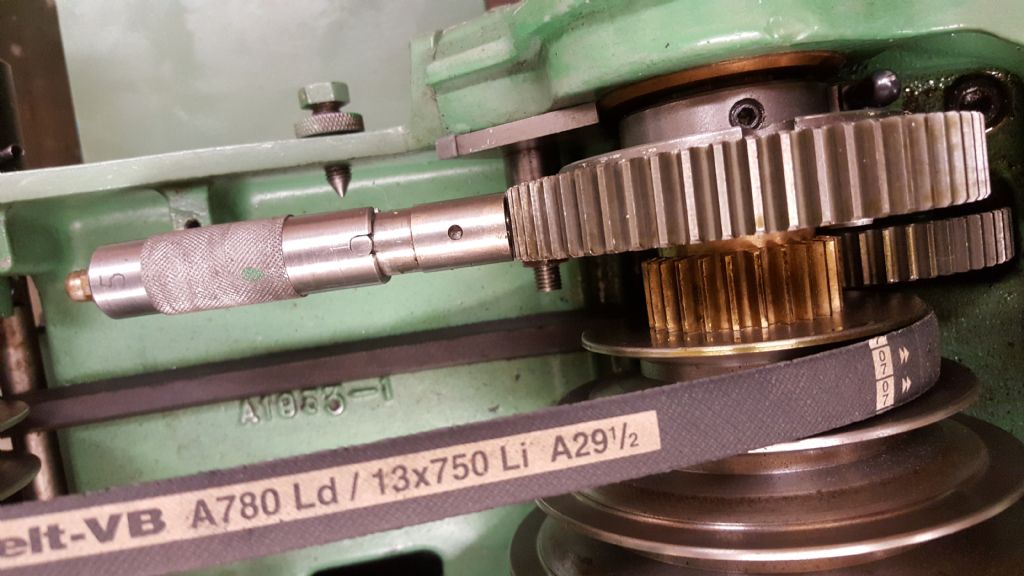

1 DON'T engage back gear as a means of removing a stuck chuck. Unless you want a second hobby or replacing gears with broken or missing teeth! There are less damaging ways of freeing a chuck, which folk mon here will tell you if you ask.

2 If you do want to use back gear, you must find and slacken or remove the grubscrew that locks the Bull wheel to the spindle. Otherwise everything will lock up because effectively you have engaged two different gear ratios to drive the same shaft. Which is impossible..

My firstb lathe was a ML7.

The replacement , and one of the reasons for buying it was the PCF.

Wouldn't be without it. Produces a far more consistent and better finish than In can.

If you wanted to, you could arrange the feed rate to produce a spiral, as if making a small self centering chuck.

You would have to be pretty skilled to be as consistent as that with manual feed.

Just my two penn'orth.

Howard

Howard Lewis.