Hello all! I’m a mechanical engineer in the US, and new to this forum.

As an introduction, about 45 years ago, I became interested in model steam engines and discovered and subscribed to Model Engineer for a few years. However with a family to support, and a house to take care of, there was no time for this hobby.

The solution? Purchase the Stuart No. 9 castings from Stuart, and the ME Beam castings from Reeves. And promise my wife that I would not start on them until retirement. Retirement has now arrived!

Many years ago I acquired a circa 1942 7-inch Rivett “speed” lathe – (no power feeds) but very solid and precise – and happily used it off and on for miscellaneous tasks. Also acquired a small Clausing milling machine. So I felt ready for a real project! I dug out the kits and looked them over.

In examining the kits, I saw that the Stuart has a 7-inch flywheel, and the beam engine a 91/4-inch flywheel. Advice on the web pointed to the beam engine as a better first model. So decided to start with it and worry about finding a way to handle the too-large flywheel later.

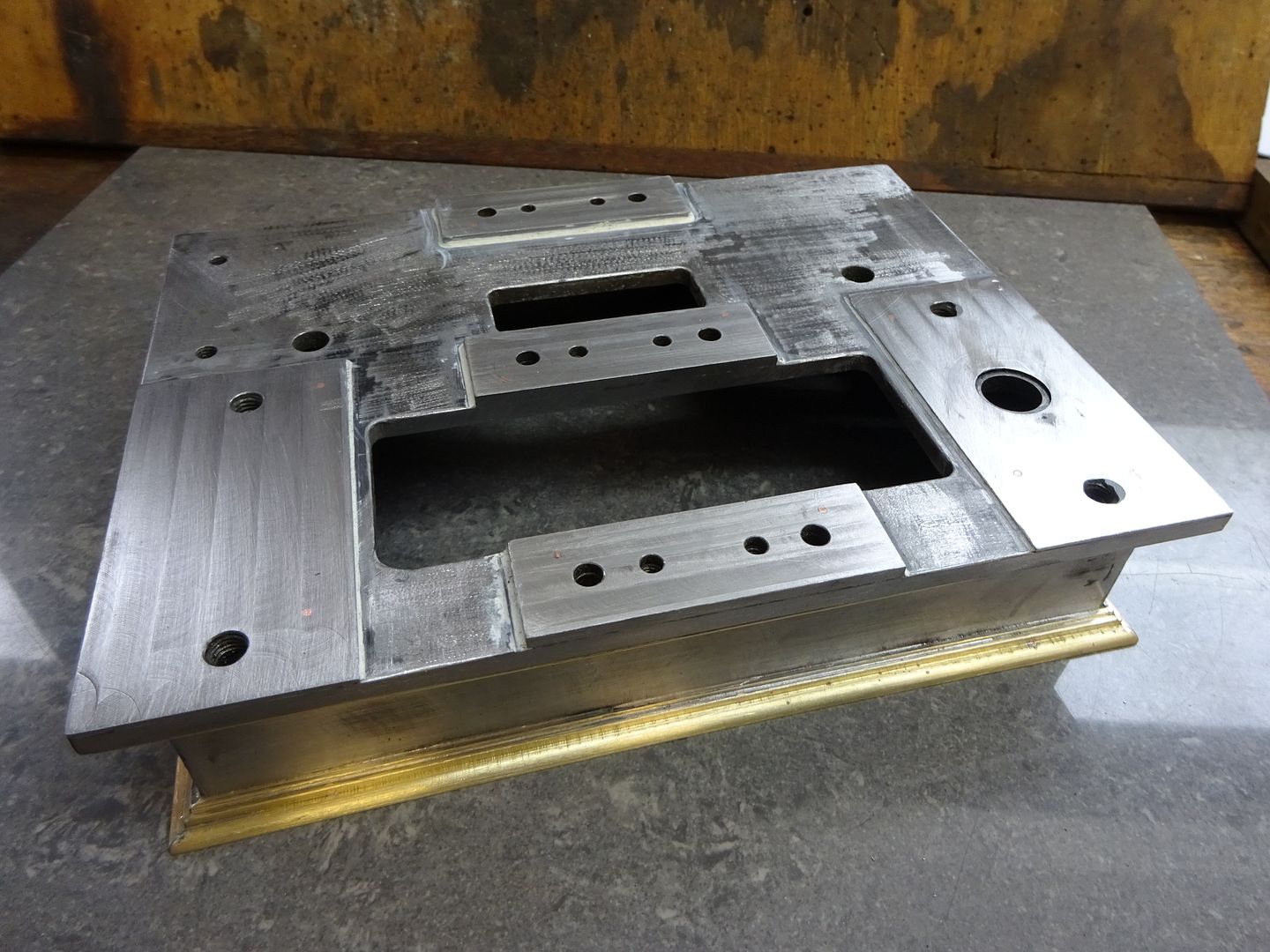

I then noticed that its cast aluminum (or aluminum alloy) bedplate is bowed upward about 1/8-inch along its length, like an inverted rocker of a rocking chair, with a slightly sharper bend upward near one end. Because the bottom flange is only about 1/8, machining it flat is not feasible.

Searching the web for ways to bend cast aluminum led to many contradictory opinions. Anneal to 400 degrees Fahrenheit, then bend while hot. Don’t bend while hot. Don’t heat at all. Use a hammer to rapidly reshape. Bend slowly. And: Don’t even try – it will crack.

So I emailed Reeves about this 45 year-old defective part. In response I was sent a current price list with the info that they were not the same company as the previous AJ Reeves. A new bedplate would cost close to or more than what I paid for the entire set of castings. And the 90 tooth gear which also had never shipped was much more expensive.

Similarly for the drawings, which never came with the kit. I asked about bending the casting, with the response that they had no technical department that could help.

So – should I try to flatten it? If so, how to approach the task. Should I purchase a new one, hoping it would arrive flat? Brunell offers castings, drawings and construction notes – are they all interchangeable with Reeves items? Do both companies provide the same drawings, or do I need the Reeves drawings to match their castings. Do they use different foundries? Is their quality and service comparable?

Should I assume a new bedplate might also be distorted, and I’d be better off fabricating one from one or two pieces of flat stock aluminum?

Not sure where to post this, but as a newbie, perhaps I can be excused as this also serves as an intro.

Les

not done it yet.