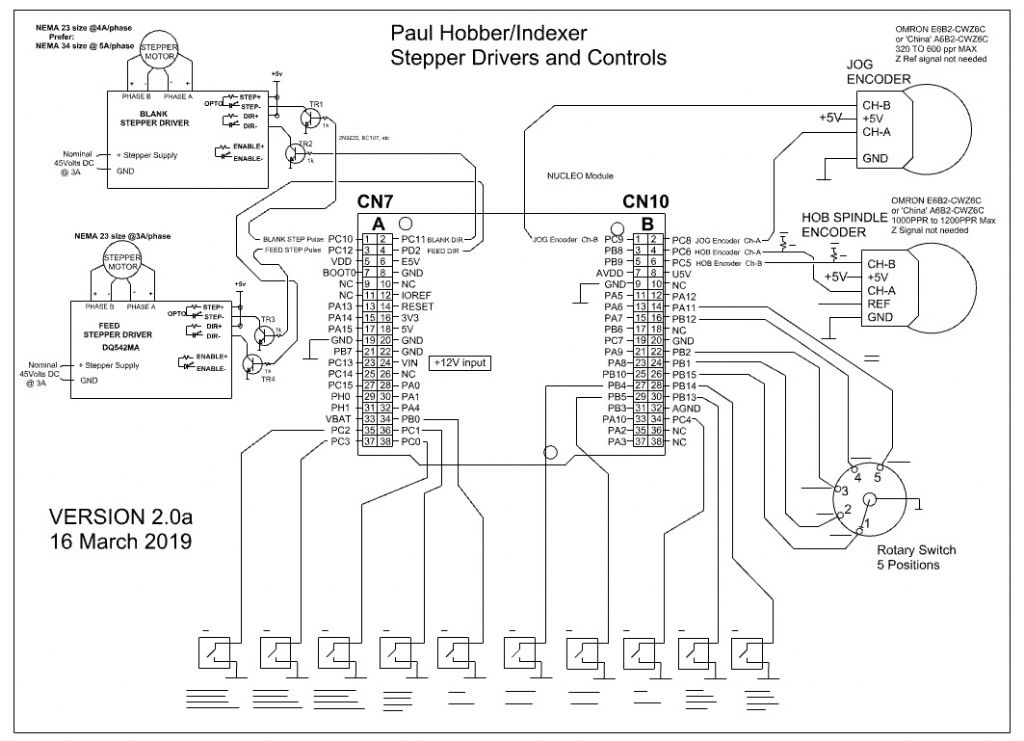

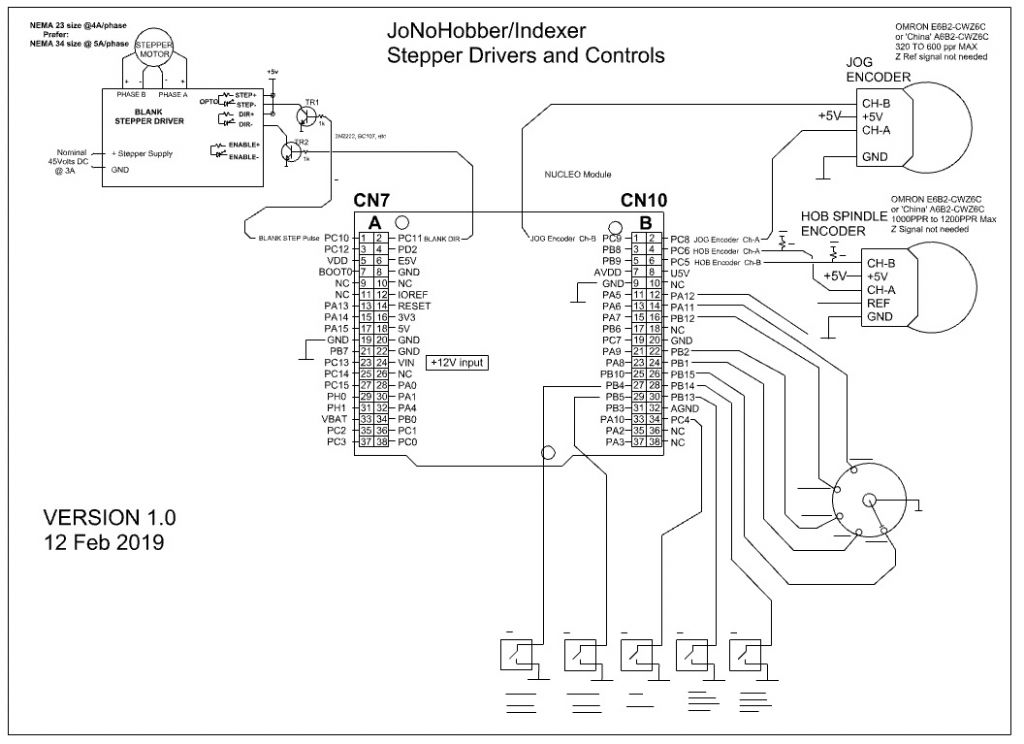

This describes basic operation of a hobber WITH AUTOFEED capability. It is easily understood from this which modes are not applicable to the non-AutoFeed mode type…

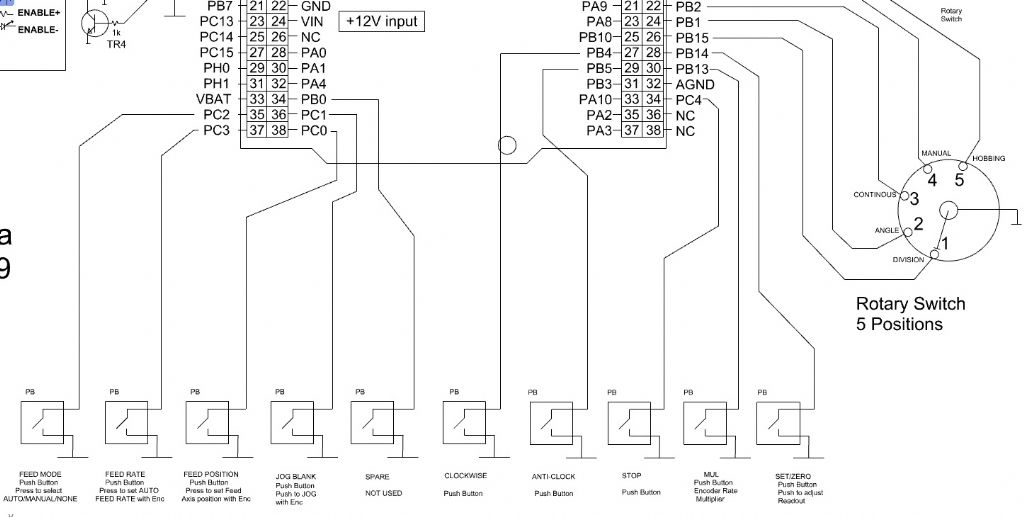

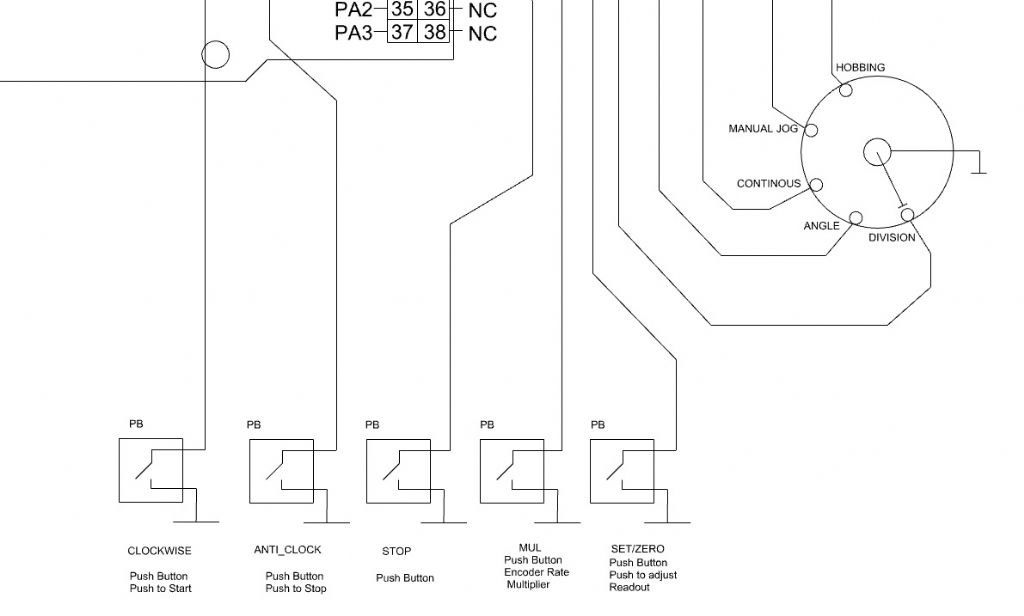

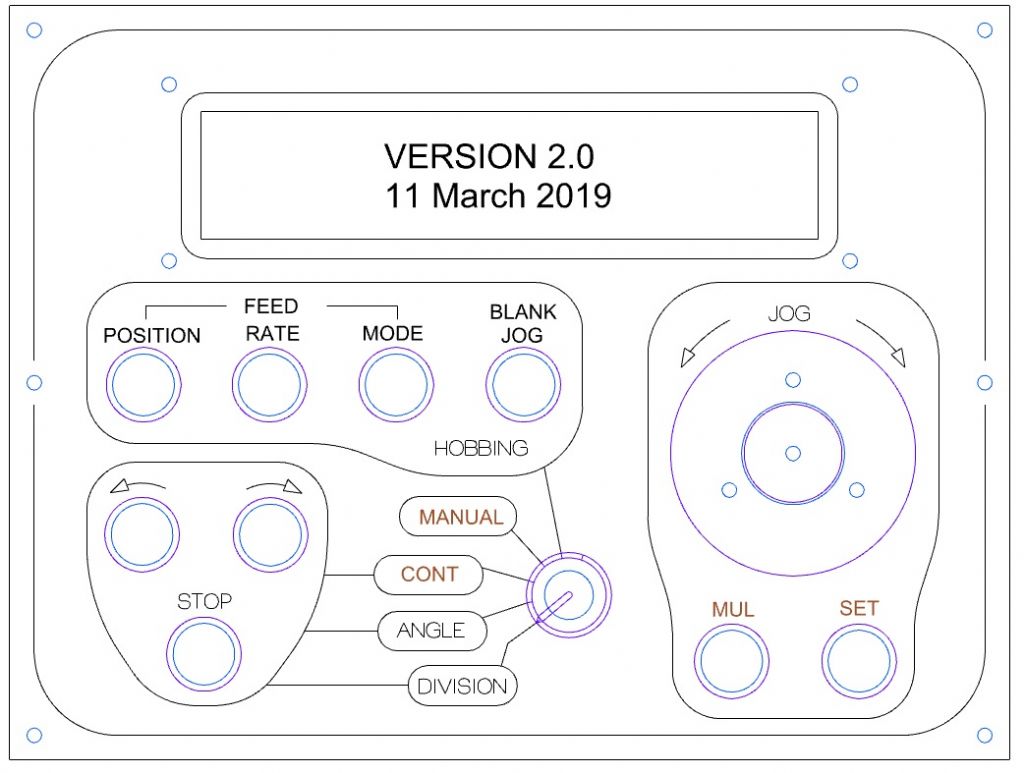

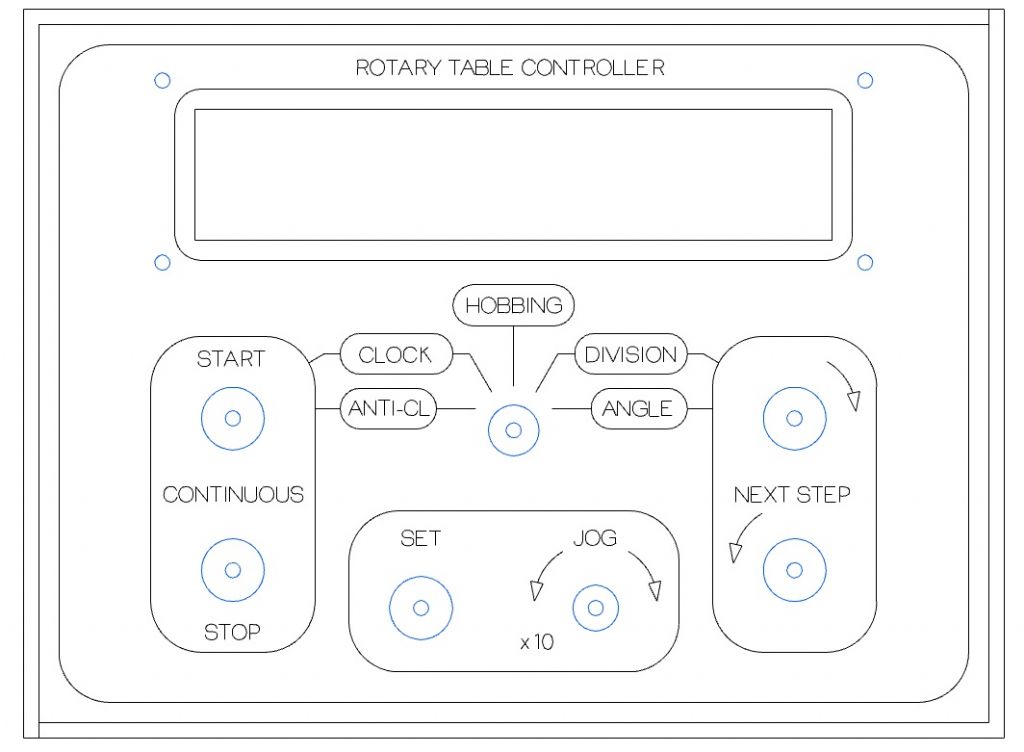

The Rotary Switch selects the various modes.

Each Mode may require the setup of some parameters, such as continuous rotation RPM, angular step size, No of divisions in the circle, No of teeth on the blank gear, etc.

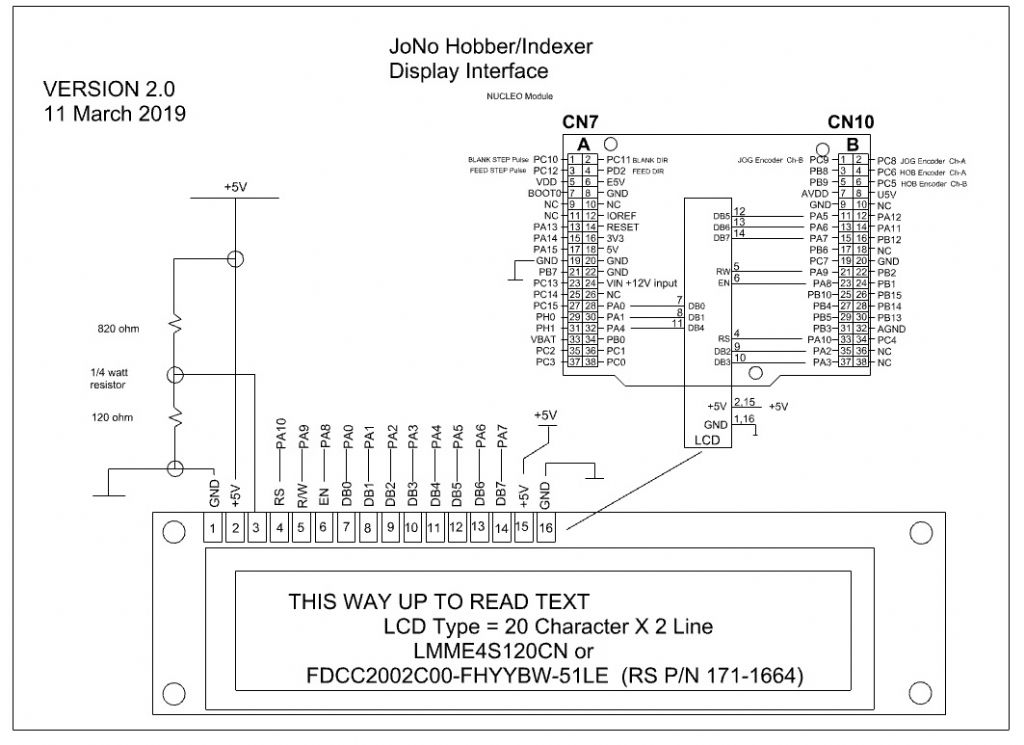

When a mode is selected, the JOG encoder is active and used to set the required parameter. The SET/ZERO switch enters the parameter as the active such as number of teeth in hobbing, angular step size, number of divisions to step, rotary table rotational RPM, etc

The JOG wheel increment size on the display can be increased by xN (N depends on your encoder PPM..) by pressing the MUL pushbutton and rotating the jog wheel. Useful when big increments are needed.

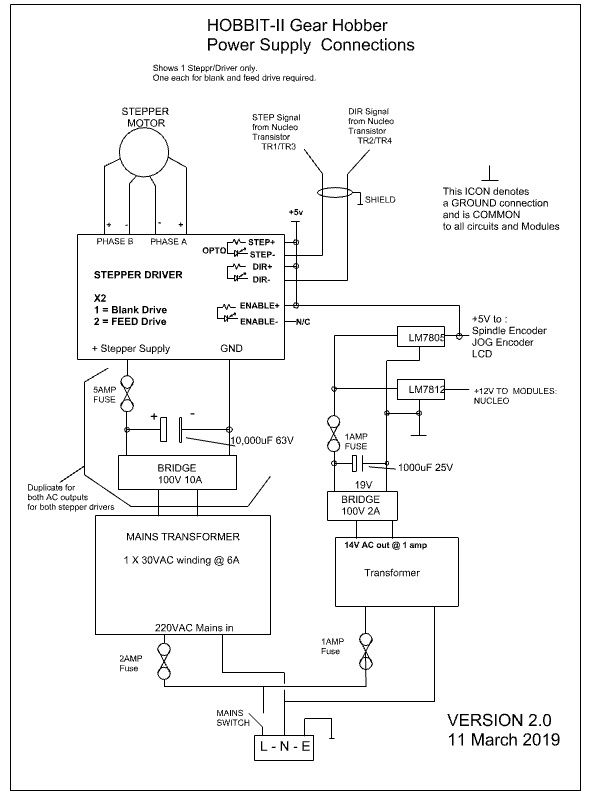

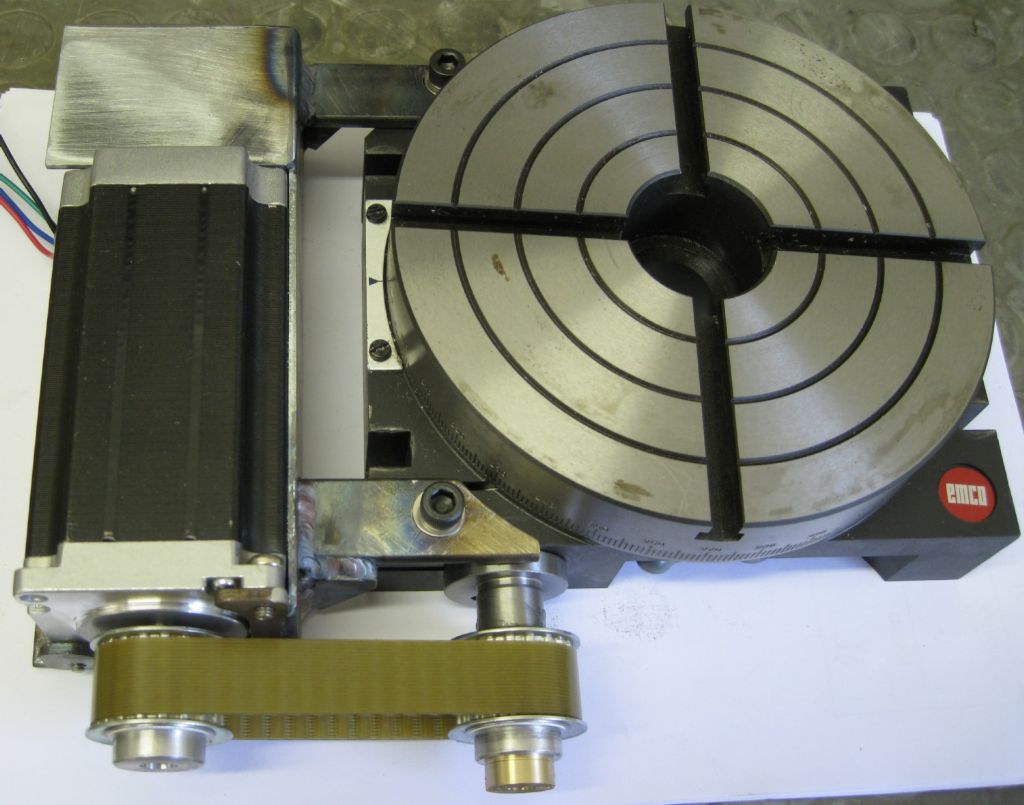

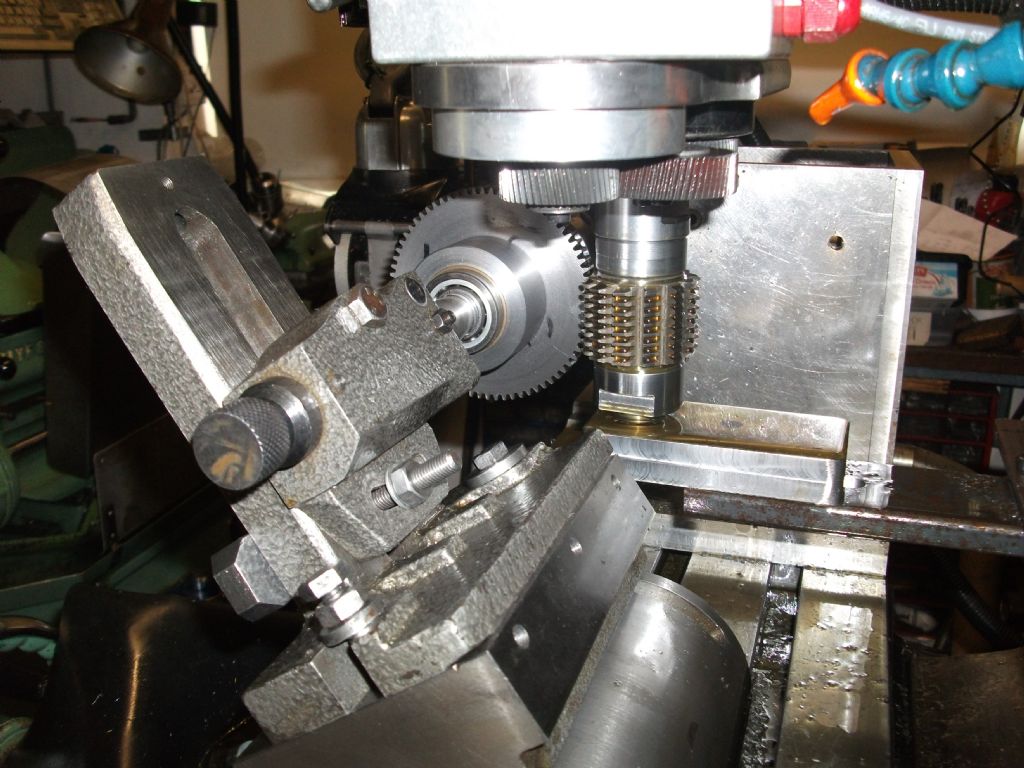

Your Hobber, rotary table, may have different gear ratios – these can be adjusted.

Rotary Switch selections:

DIVISION

The JOG wheel is used to set a division increment, eg, say 360deg divided into 20 segments, ie each segment = 18degrees. Press SET/ZERO while using the JOG wheel to set the division value. Release SET/ZERO when done. When the ‘>’ or ‘<’ PB is pressed ( either clock or anticlock), the table will turn in that direction by the set division, for each press. The table can be set to a specific start point by first using MANUAL mode, below. Then selecting DIVISION again and using the ‘<’, ‘>’ buttons , the process will step on from that point each time. The number of division steps selected is displayed, as is the current cumulative division step number.

ANGLE.

The JOG wheel is used to set an angular increment, eg, say 5deg. Press SET/ZERO while using the JOG wheel to set the angle value. Release SET/ZERO when done. When the ‘>’ or ‘<’ PB is pressed ( either clock or anticlock), the table will turn in that direction by the set angle, for each press. The table can be set to a specific start point by first using MANUAL mode, below. Then selecting ANGLE again and using the ‘<’, ‘>’ buttons , the process will step on from that point each time. The selected step angle is displayed, as is the current cumulative angle value.

CONTINOUS.

The JOG wheel is used to set an RPM at which the table will rotate. Press SET/ZERO while using the JOG wheel to set the angle value. When the ‘>’ or ‘<’ PB is pressed ( either clock or anticlock), the table will turn continuously in that direction at the set RPM. Press STOP to stop rotation.

MANUAL.

This will rotate the table as the JOG wheel is rotated – useful when milling a radius, setting the table to a specific mechanical reference point, etc. Pressing SET/ZERO at any point in this mode will reset the angle display to 0 degrees as the reference start point.

HOBBING.

When selected, first use the JOG wheel to select the number of teeth to be cut, by pressing SET/ZERO and rotating the jog wheel. Release SET/ZERO when done.

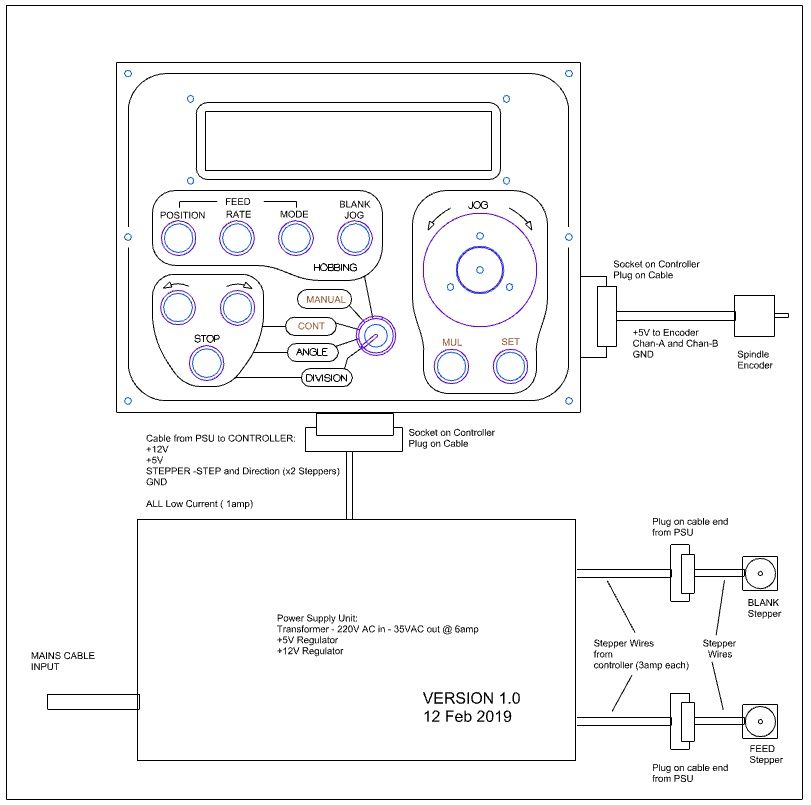

5.1 BLANK JOG

The BLANK can be positioned as required by pressing and holding BLANK JOG, while jogging the blank with the JOG wheel.

5.2 FEED MODES

Since there is the option of Auto-feed of the cutter advance, the feed mode also needs to be set up ( Position, rates, auto/manual)

5.2.1 POSITION:

To position the cutter in relation to the blank, ie, almost touching, ready to cut, press FEED POSITION and use the JOG wheel to move the blank and cutter into the correct relationship.

5.2.2 FEED RATE

To set the feed rates ( in mm per blank rotation) press FEED RATE and use the jog wheel to set the value.

5.2.3 FEED MODE

The feed mode can be AUTO or MANUAL or NONE. This is selected by repeated presses of the FEED MODE button and will show on the display.

5.2.3.1 AUTO MODE

The feed will proceed in the selected mm per blank rotation and starts when the hob spindle starts running.

Pressing ANY other HOBBING mode button, eg, BLANK JOG, FEED POSITION or FEED RATE will immediately CLEAR the feed rate to NONE and if in AUTO-FEED, FEED will STOP – no AUTO feed will take place and the JOG encoder will not cause manual feed. Use FEED MODE to re-select the desired feed mode.

The FEED Mode can be changed on the fly, with the machine running or not. This allows manual take-over of feed, or AUTO from manual, or change of feed rate, and then back into auto, etc.

5.2.3.2 MANUAL MODE

In this mode the JOG encoder will drive the FEED axis Stepper. The JOG wheel is disconnected from ALL other functions and only generates FEED increments. Pressing ANY other HOBBING mode button, eg, BLANK JOG, FEED POSITION or FEED RATE will immediately CLEAR the feed rate to NONE, and the JOG encoder will not cause manual feed.

The FEED Mode can be changed on the fly, with the machine running or not. This allows manual take-over of feed, or AUTO from manual, or change of feed rate, and then back into auto, etc.

Gear Ratio Selection.

This is effected by selecting MANUAL MODE and then pressing and holding the ‘<’ button. Each press of the ‘>’ button will then cycle through the gear ratio options for rotary table use. Selectable ratios are 40:1 and 72:1. The HOBBING mode defaults to 40:1 ratio. This can be changed in software to any ratio you wish..

For those still awake, and interested, let me know what else you may need – greater detail etc is probably best by PM or emails.

Joe

Gary Glenn.