Hi Andrew,

Apologies for the delay. The new arbors are due in around 22nd January 2020.

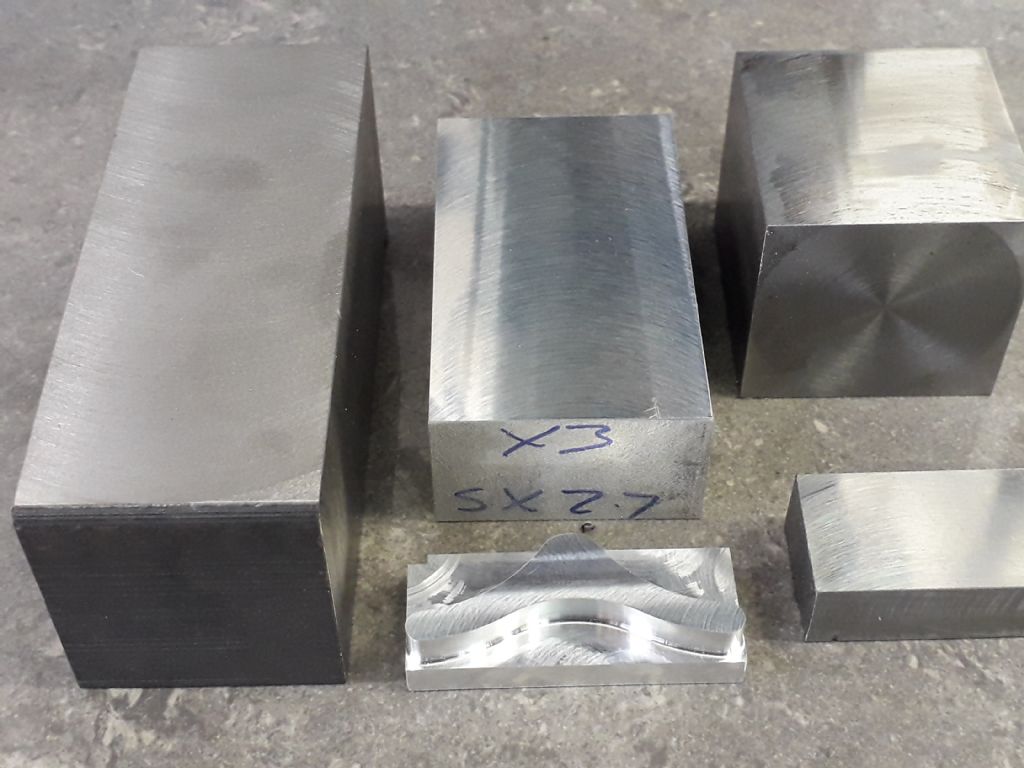

The main difference between the new and the 'reduce to clear' rage is that the reduced to clear range have specially made screws to secure the shell mills to the arbors, rather than socket cap head type screws being used on the new range. Please see link to the spare screws.

The arbors in the 'reduced to clear' range will fit the shell mills, but in certain cases, the flange type screw head may need to be turned down, or you can replace it with 'normal' socket cap head screws.

Generally, makers of the shell mills are totally different from makers of the arbors. Makers of arbors really have no idea about which type/maker of shell mill is going to be used with their arbor. Both items being generic in their own way… to a certain extent. So, most of the time, the locking screws are either the flange type or general socket cap head screws.

With the new range, we managed to make the new arbor making factory 'talk – discuss' with the shell mill maker. The idea being to try and match the arbor screw fit with the shell mill. Although this is a new product range for us, long term aim is to try and get consistency, so we also got the shell mill maker to 'work – discuss' with the factory from whom we buy the inserts.

Ketan at ARC.

JasonB.

JasonB.