Posted by duncan webster on 30/03/2019 00:36:01:

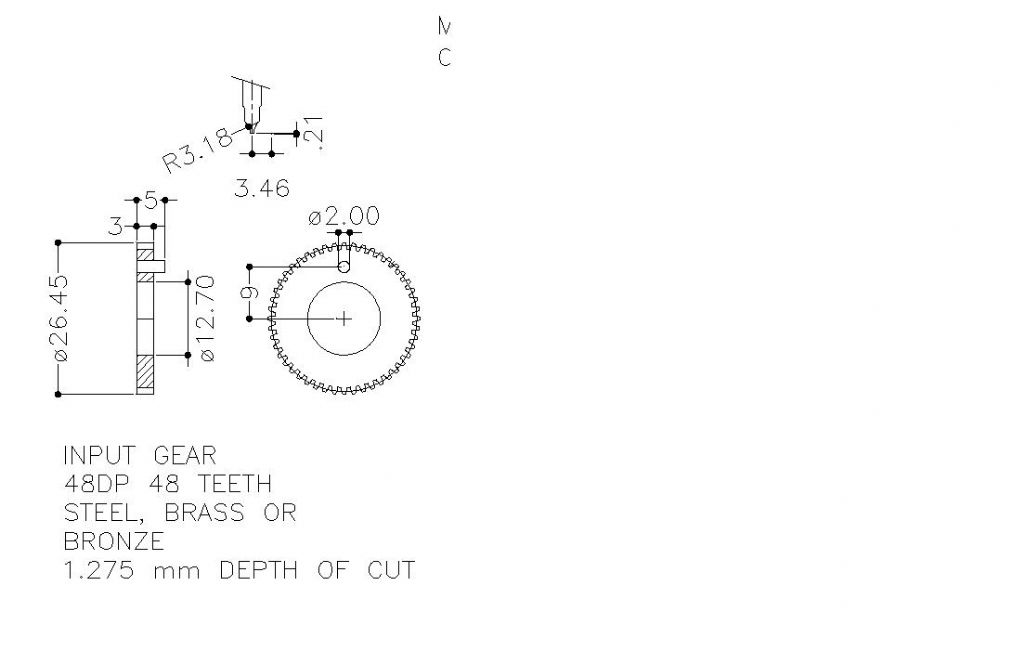

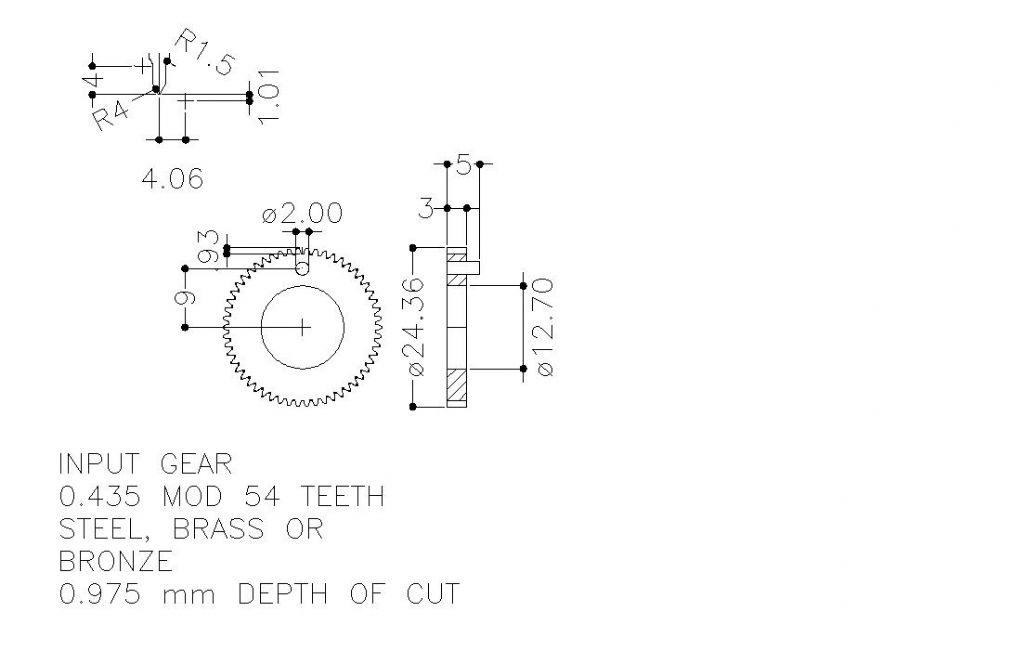

This sounds like yet another instance of ME/MEW taking contributors drawings, redrawing them and getting them wrong. Previous editors (not the present incumbents) have denied that they redraw anything, plainly not correct. Why not just publish what is sent in, then if it's wrong they can blame the contributor. Even I can convert a dwg to a jpg, which can then be treated just like a photo.

Hi Duncan,

There are a number of issues, chief of which is we need to be able to manipulate line weights and font sizes to suit the size at which the image is published, or move components around to fit the layout. Clearly there's no way way a contributor can anticipate these. very often drawings are provided as a single sheet that has to be split up.

Also, the standard of drawings varies hugely, not everyone is as experience a draughtsman as Graham!

DWGs are (in my experience) incredibly prone to losing lines or changing details on export; I have no idea how industry copes. A DWG done in one package isn't always even openable let alone accurate opened in another package (I got a DWG or DXF a couple of days ago that wouldn't open properly in either Alibre or Turbocad).

If converted to a jpeg we can't do anything to edit them, and they can lose definition and are almost impossible to change if there are any shortcomings.

The ideal is to send me PDFs as PDFs are what we need for publication, and they really are portable – everyone sees the same things, and we very rarely get errors introduced when they are adjusted because changing overall size, line weights, fonts or moving groups can be done without changing any relationships or text (usually).

In this case I think the problems came when I exported Graham's original drawing to pdf; it's by far the best if authors do the export themselves so they can check if any errors are appearing. Graham now produces his own PDFs and I recommend this approach to everyone.

Neil

Martin Kyte.