Posted by Lambton on 28/01/2019 09:32:19:

…

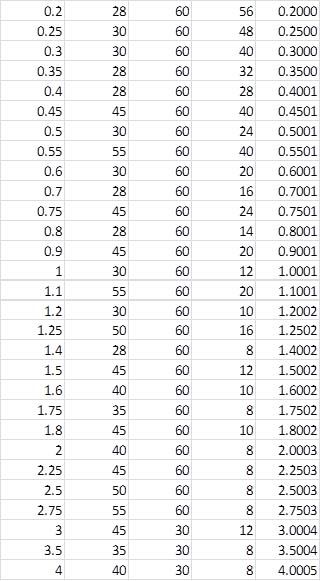

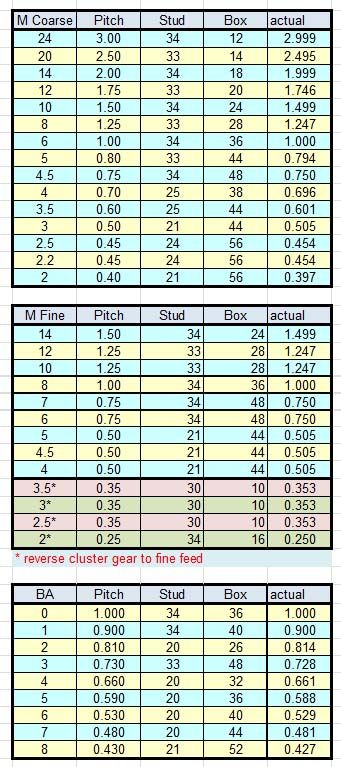

No lathe with an imperial lead screw can cut a truly accurate metric thread unless a 127 tooth gear is used. Despite this fact both the official Myford conversion set and the 33, 34 toothed input gear method are capable of producing metric threads accurate enough for all practical purposes.

…

Being in pedant mode this morning, I have to insist Eric's opening sentence should be 'No lathe can cut a truly accurate thread'. Never mind if it's imperial or metric.

The reason is, no matter how expensive and well-maintained, the way a lathe works causes unavoidable errors – they are imperfect machines. Making a lathe that can cut accurate to rather better than a thou isn't hard. Making a precision lathe to cut accurately to tenths is far more difficult, and the machine has to be maintained in top condition and operated with extreme care. Achieving accuracy surpassing tenths on a lathe is so difficult it's better to dump the lathe in favour of some other technique. Highly accurate threads are made by Grinding and Lapping, not by turning.

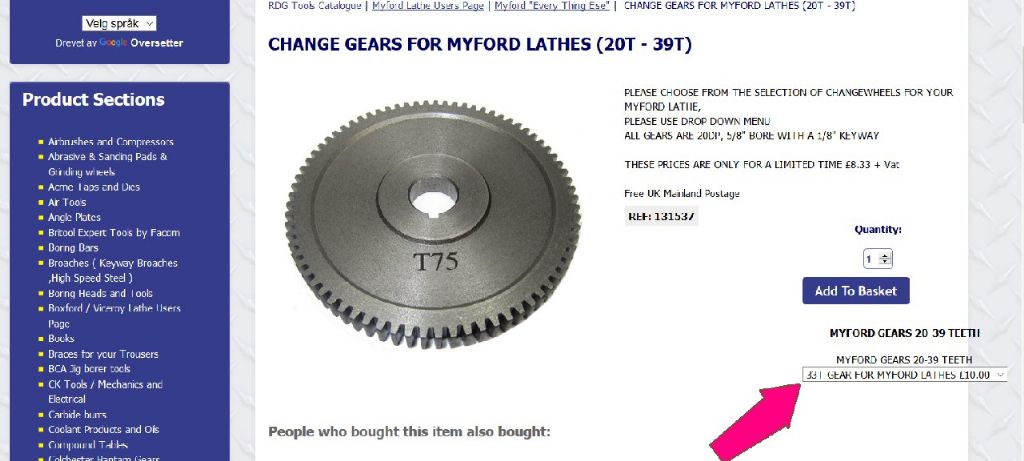

Also in pedant mode, I don't believe it's true that a 127 tooth gear is literally essential, though it's certainly by far the most straightforward way of producing suitable ratios. But there are many other combinations of gears that can produce metric pitches on an imperial lathe. However, it's a tad theoretical unless you like hard sums – it's easier to have a 127 toothed gear rather than dozens of other gears and a computer!

I completely agree with Eric's main point though – very often you can get 'close enough' by putting 63, 33, or 34 in the chain. Or some other combination! Although it's reasonable to strive for the best result possible, it does seem quite a few hobbyists lose their sense of proportion and put a lot effort into trying to do better than necessary. Cherry Hill makes top-quality models – I polish turds…

Dave

Chris Bradbury.