Straight cut gears can be meshed with a leadscrew or similar thread without offsetting to the helix angle. You just make either the gear teeth or the profile of the thread thinner to accommodate.

I did this with great success on my fabricated Versatile Dividing Head. I used a straight-cut Myford 60T change gear as the main "worm wheel" and turned the worm teeth to a thinner than normal profile so the worm shaft could be twisted from its natural angled position to one straight in line with the Myford gear. Yes, it gives point contact, which is sufficient for positioning only purposes like dividing heads and thread indicators.

I can't claim the idea as my own. Martin Cleeve in his book Screwcutting in the Lathe outlines the thinning of teeth/thread to achieve straight alignment between worm and and straight-cut gear.

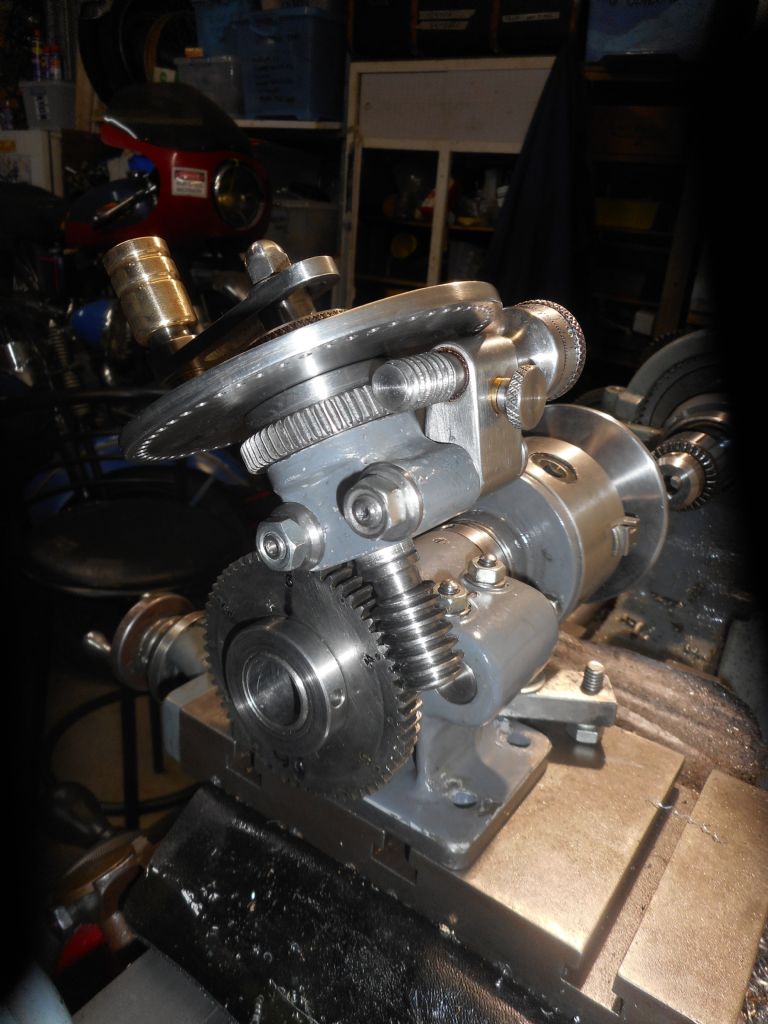

The pic below shows the straight-cut main gear with the worm mounted square to its axis, using the above method. The smaller "worm-wheel" was made at home with the teeth straight but skewed at the helix angle of the worm, just for the sake of it. When cutting the gear it was no extra bother to kick the vertical slide around to the helix angle and cut the teeth skewed.

So for a thread chaser dial, proper helical gears would be overkill in most cases. Skewed would work perfectly and straight could be made to work perfectly also, if you cut your own gear with thinner than normal teeth.

Neil has a nice article on file on this very topic so I expect it will appear in MEW one day with all the gory details.

Edited By Hopper on 10/08/2018 00:56:13

Edited By Hopper on 10/08/2018 00:59:41

Howard Lewis.