I can't believe I'm reading the confusion in this thread… The late, lamented George Thomas wrote pretty much all anyone could ever need to know about parting off (and many other topics) in his many comprehensive Model Engineer articles and his books. Perhaps it's time for a re-run?

Merryweather's article is BAD and MISLEADING (yes, I'm shouting!). It may not be his fault – perhaps it has been mangled by editing or production errors, but it doesn't belong in anything with aspirations to be an authoritative journal. As printed, his explanation is faulty. What determines in which direction a tool is deflected under cutting loads is the relationship of the direction of the resultant force on the tool to a line joining the cutting tip to the centre about which the tool and its holder, toolpost, etc. can rotate. (By rotate, I mean move by flexing. It will certainly flex – nothing is infinitely rigid, and Myfords certainly ain't!). A rear parting tool, inverted, with the lathe running in the 'normal' direction is successful at avoiding dig-ins because, as it is loaded, it tends to be deflected up and away from its point of contact, thereby relieving the forces upon it. Just think how it would move if its toolpost were hinged to the cross-slide. Similarly, but the opposite, for parting-off with a tool in the 'normal' toolpost.

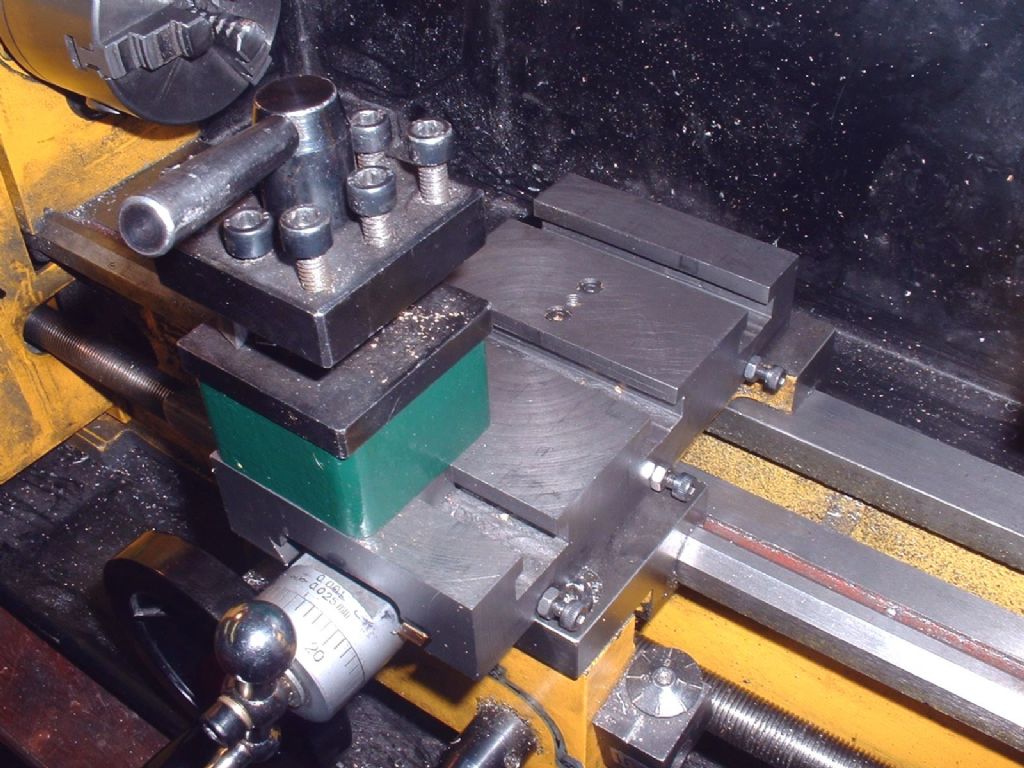

The article is not clear. Merryweather's Fig. 5 bears no relationship to the photos of his toolholder set-up. I THINK he must part off with his lathe running in reverse: there seems to be chip build-up on top of the tool (photo 3). This, of course, isn't a good idea for lathes with screw-on chucks… If this is correct, photo 3 suggests that the tool and holder will be deflected clockwise, pivoting about its mounting to the cross-slide, and therefore relieving the cut, as load is applied. If this is the case, the set-up could be reversed, with the tool-holder mounted 'in front' of the spindle, and the lathe run in the 'normal' direction. It is, in fact, more-or-less a re-invention of the 'spring tool' (look it up), although rather less springy….

Another reason given for the success of rear parting-off tool-holders, especially on non-rigid Myfords, is because the tool loads lift the cross-slide, minimizing dovetail clearance, and tighten-up the whole shebang, reducing chatter likelihood. This doesn't apply to inverted-vee beds, of course.

Mark C.

I do have a full tine of (old formula) yellow smoothrite that matches the lathe and one day I will do a full repaint!

I do have a full tine of (old formula) yellow smoothrite that matches the lathe and one day I will do a full repaint!