Hello all (specially Harold Hall’s grinding rest user)!

A while ago I build the Harold Hall’s grinding rest and then I ground some drills with it. However didn’t make a teste of my work as deep as I should. So, now, I find that the drills I grind with the grinding rest do not show the expected geometry I can see in the book (Tool and cutter sharpenning pages 120, 121, 122) and they don’t cut metal in a smooth way. One of the 8mm drills sharpened with grinding rest even cut steel (cold rolled steel) in chips instead of two spirals and the vibrations of the drilling machine were as if the drill were hammering the metal…

The cause may be because I have some doubts in reading and interpreting (my mother tongue is the Portuguese) the “Tool and cutter sharpening”.

In referred pages, Mr. Hall states the following steps:

1 – table tilted down 27 degrees

2 – table rotated about one degree so the grinding only takes place in front edge of the wheel

3 – put the drill in the vee support with the cutting edges parallel with jig’s base

4 – adjust the drill end stop

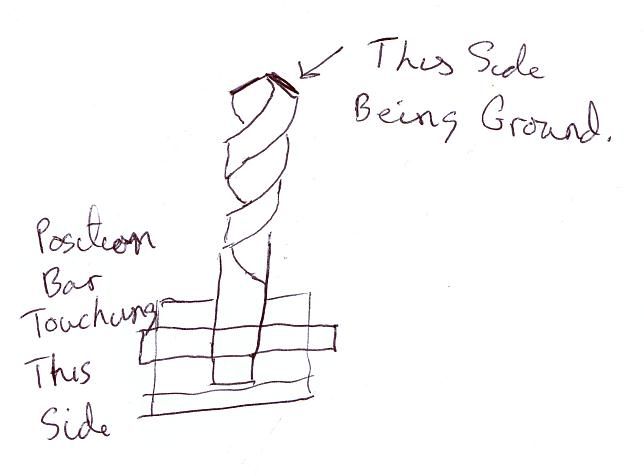

5 – with the positioning bar against the edge of the end stop base fasten it to the drill shank ensuring the two halves are parallel

I have a doubt about this step: which edge? The left or the right? Is the side irrelevant? There are two possible edges usable for the purpose.

6 – start grinding de first face using the fence as a guide

7 – rotate the drill 180 degrees in the jig for sharpening the second facet

8 – set the angle of the table to 10 degrees and grind the third and fourth facets until the chisel has changed to a point with all four facets meeting at the same spot.

I’ve been facing dificulties in producing facets with a geometry equal to the image in page 122 of the book.

Is there any advice You can give to me in order to obtain better results? Can You clear my doubt in point 5?

Thanks in advance

Dias Costa

dcosta.