I wonder what other members are making of this article?

I must admit to having been involved with turbomachinery design most of my working life, so I am finding the basic theory a bit laboured. That said, I hope the author is going to get on to the reality of designing miniature steam turbines. It seems to me the major problems are:

1) Selection of type – radial inflow, outflow, axial, impulse, tesla. It seems to me that with the low flows of steam available in miniature the choice really comes down to impulse or impulse. There was an article in the seventies about using a jet pump to entrain air and then running the mixture through a radial inflow unit, which has always fascinated me.

2) We are all agreed that the efficiency of small units is very low, but how does one get a reasonable estimate of how low? Without that number, you cannot even estimate a required steam flow, hence no idea of nozzle size hence no idea of blade height.

3) Most agree that bearings can be a problem due to high running speed, but also will there be any guidance on calculating bearing loadings – particularly axial load?

4) Will there be any guidance on blade design – row height, solidity, blade number? It looks as though we might get on to blade angles, but there has been no sign of a velocity triangle yet!

5) Blade manufacture – there have been a number of methods put forward over the years for something approximating impulse blades such as cut using a hole cutter approach, or profiled using a small end mill and cams – even including pen nibs as blades! There doesn't seem to be anything on using insterted blades with a proper fir tree root.

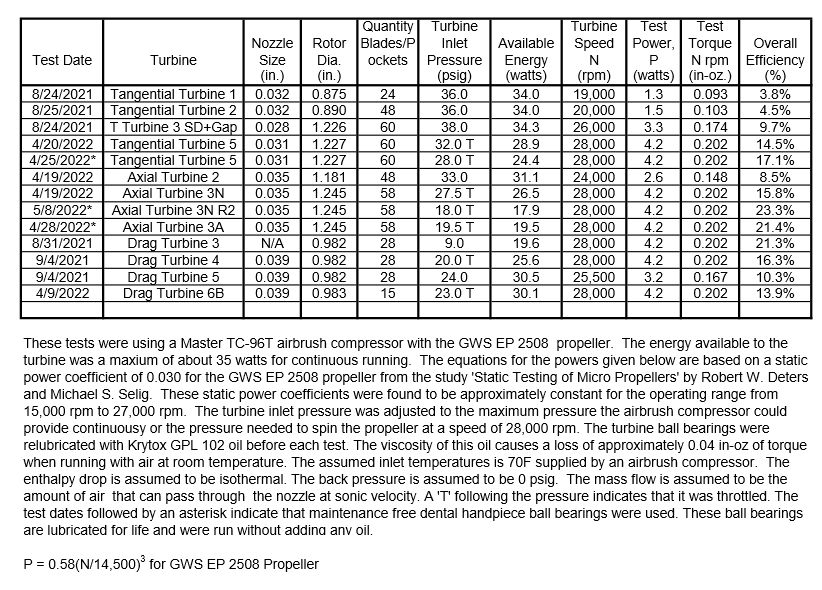

6) Tesla – I am glad the author is not blinded by the mumbo jumbo on that one. I agree that quantitative data on EFFICIENCY is as rare as hen's teeth.

I hope the articles will allow us to move forward from grossly inefficient windmills, but I am yet to be convinced.

Hope this generates a bit of discussion.

Martin

Turbine Guy.