16mm IDRIS

16mm IDRIS

- This topic has 182 replies, 13 voices, and was last updated 12 May 2016 at 20:15 by

John Rudd.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

saw would resolve this.

saw would resolve this. .

.

…….

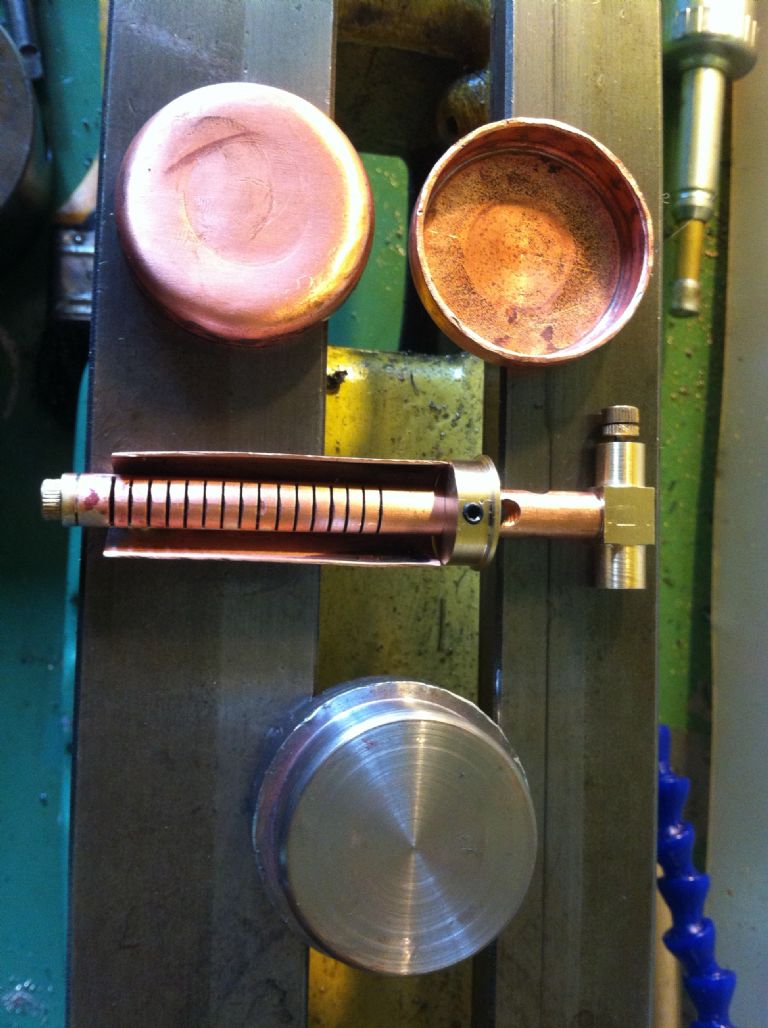

…….![img_0922[1].jpg img_0922[1].jpg](/wp-content/uploads/sites/4/images/member_albums/103995/595003.jpg)