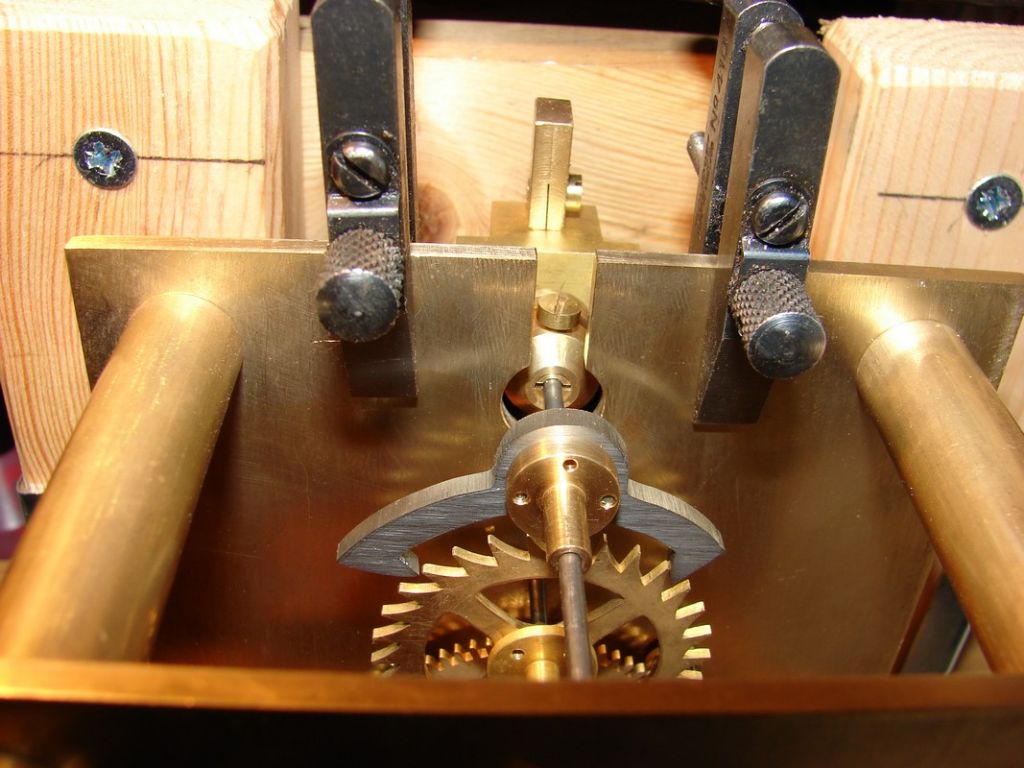

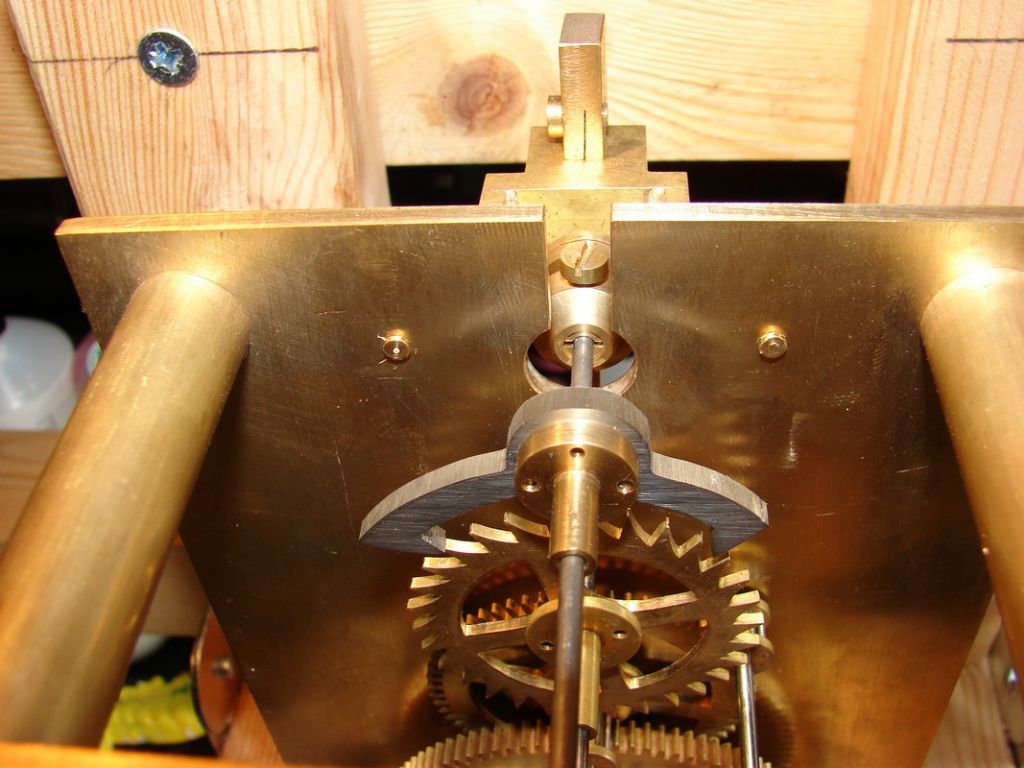

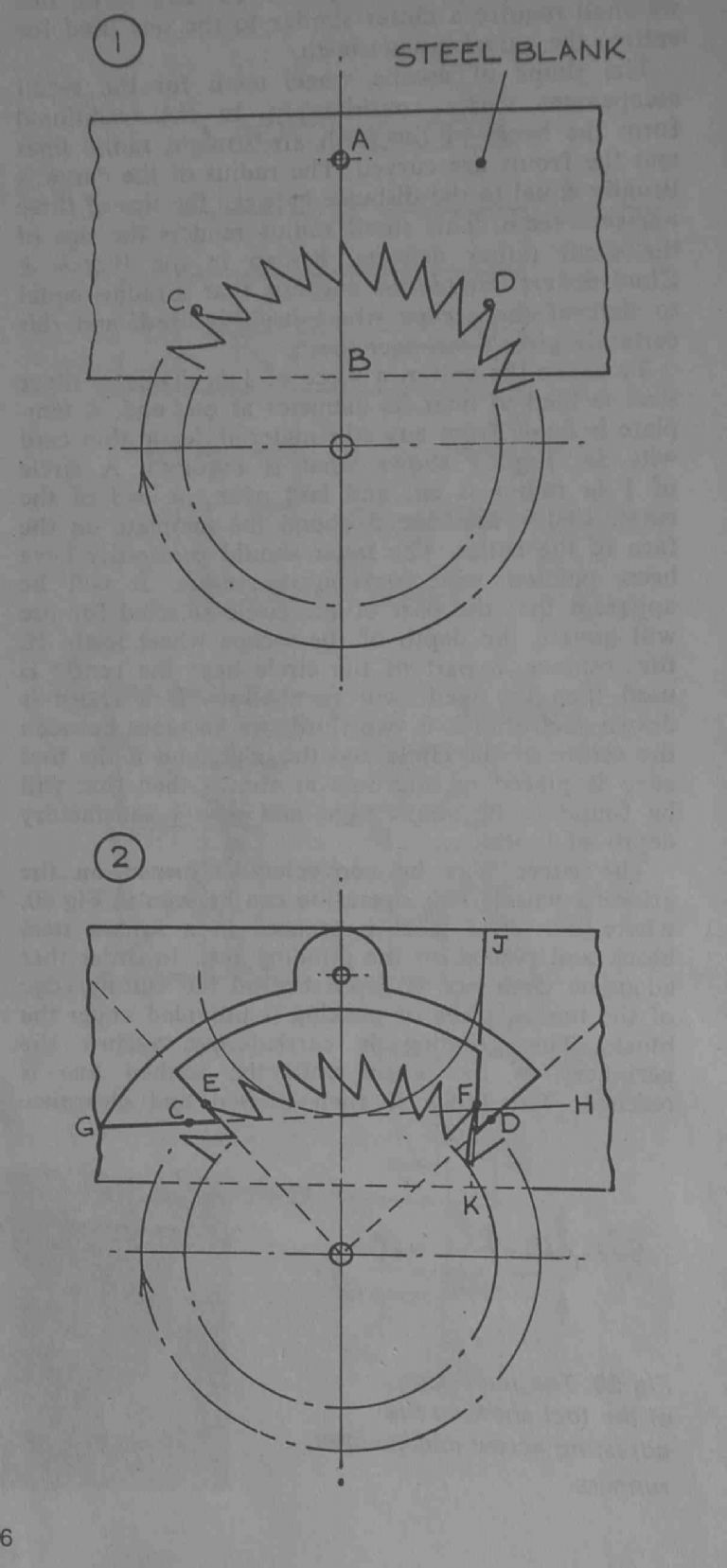

Alan, the drawing in photo 2 is to show how to generate the shape of the pallets, which are actually shown in mid position (pendulum mid swing (vibration) and the escape wheel is actually locked at that point, although there would in reality be a small degree of clearance between the wheel teeth and pallets at this point,

The pendulum (and hence the pallets) as it swings away from that central position will move one pallet face off a tooth and the other deeper into mesh, this will cause a small reversal of the escape wheel at that point and why it's also called a 'recoil' escapement as well as 'Anchor', the pallets 'rock' with the swing of the pendulum,

As the pendulum swings t'other way, it will move that deeper engaged pallet face out of and away from the locked tooth with the other pallet face moving towards the other tooth, at some point, the tooth that was engaged will be released and the tooth where the pallet is moving towards it will be caught by the pallet, the same happens when the pendulum swings back, but on the other tooth,

A bit of a clumsy description but hope it helps some,

You will need a depthing tool of some arrangement to set up the pallets to the escape wheel, because you need to get the pallet faces locking and unlocking the escape wheel as close to the teeth as possible without it actually locking up, otherwise the drop of each tooth before hit strikes the pallet face (and creates the 'tick' or 'tock' when the escape wheel is released may be too large and will waste power (as well as ticking Very loudly),

The animation in the link below may help you understand its action:

**LINK**

There are several animations listed and linked on the site if you go to the homepage,

John.

Edited to get rid of a smiley?

Edited By RJW on 12/02/2017 09:57:18

Zachary Rohrer.