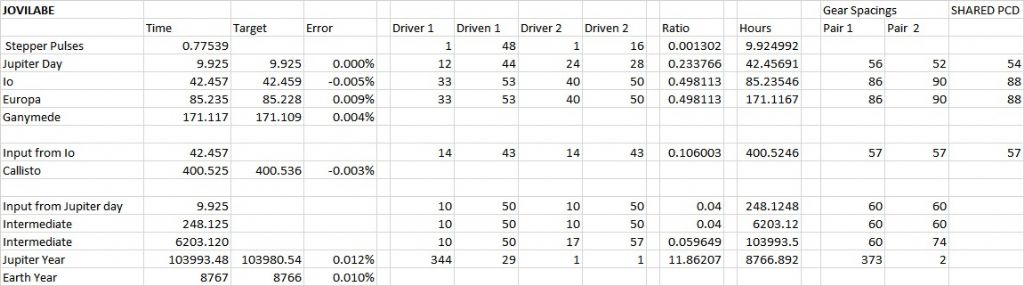

I've completed the basic calculations for a Jovilabe (an orrery that shows the motion of Jupiter's moons). This is just for the four Galilean moons, plus the Earth and Sun (at a different scale of course…)

Starting with Jupiter rotating once every 9.925 hours, the first pair of gears will sort out Io with negligible error. This can be used to predict when the red spot will appear.

Although the three inner moons have a 1:2:4 ratio, in reality their pattern lags slightly as the 'perijove' of Io precesses around the planet, but i have solved this in two ways and get the same figure of 1:2.007 between each pair of moons. I've decided to accept an error of about 2% in the moon's positions over five years.

Calisto could be geared to the central Jupiter drive or from the Io pipe, I have a gearing for the latter with negligible error.

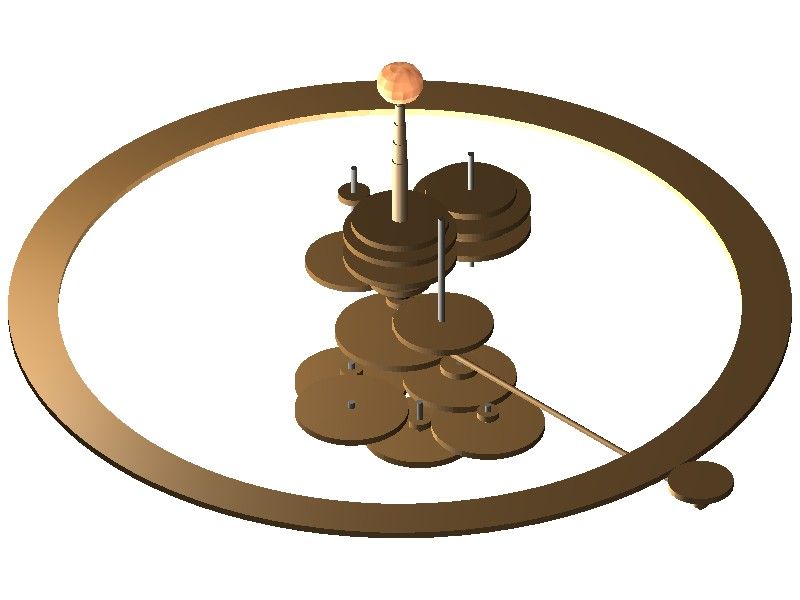

A bigger challenge was moving the Earth in relation to Jupiter as this determines the angle the moons are seen at. It get easier if you decide on a point to be the sun. The ratio is a massive 10477:1, and yes, 10477 is a prime! I found a simple train with five pairs of 5:1 ratio plus a single 57:17 gives 10477.9:1 so an error of less than 1 part in 10,000 every decade should be OK.

The ratio of Jupiter's year to the earthly year is incredibly close to 344:29.

A large stationary 344-tooth ring with a 29-tooth gear rolling around the outside of it at Jupiter's orbital speed will provide a pace for both the sun and the earth. Obviously this creates a 'joviocentric' perspective, I could fix the position of the sun, but I think that would look less interesting and take a lot more room for little benefit.

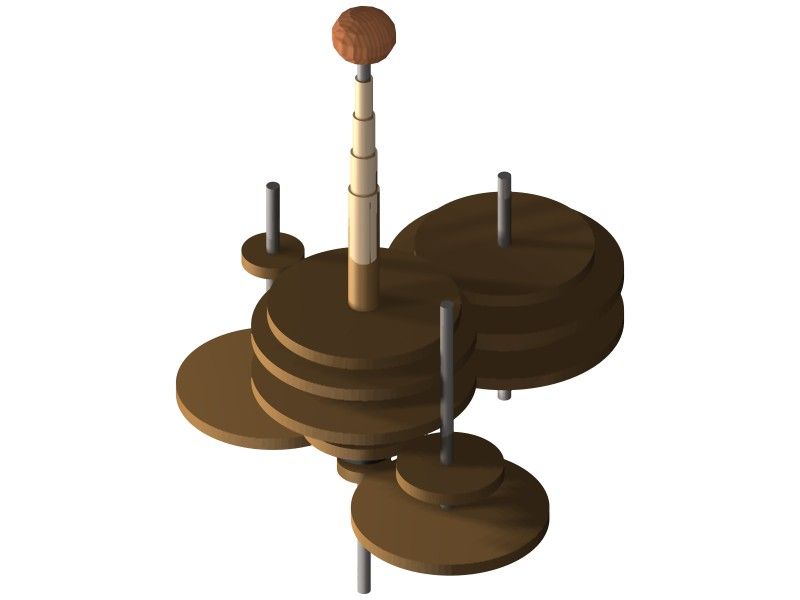

If I do embark on yet another unfinished project, this will require 28 gears, assuming the driving stepper motor is geared down once to give a smooth rotation to jupiter.

All this should fit into a 30cm diameter base, perhaps 10 cm thick.

Neil (boggled and buried under a large pile of scribbled-on A4).

Dave Goodchild.