Well, started a few days ago….

Started to work out how and where to install a belt-type vari-speed drive for my Denbigh H4 mill, and realised my best move is to fit the motor to the unit's original motor-plate. This needs new mounting-slots.

The plate is held to the rest of the machine by several cheese-head screws well stuck in their counterbores, so needed an impact-wrench driver to loosen them.

Cannot find anywhere the driver I have owned for years… Trip to Eurocarparts to order one.

Collected it yesterday morning; used the sunshine and trip out as the excuse to go for a walk on a stretch of coast path I had never previously explored (I've lived in this area only since 1959).

Started using it in the afternoon, and the screwdriver tip broke in about the third screw. It appeared sort of hardened but not tempered, and I was using only light hammer-blows. Luckily I completed the work with the second bit.

TODAY: Returned to the shop, receipt in hand, to order a new tip.

Too cold to inspire me but I made myself walk to my usual corner shop (exercise!), then go to the workshop in the early evening. Overalls, extra socks, fleece hat – and leather gloves to handle a lot of cold steel.

Moved the mill, only a little, but so it is now at right-angles to the wall, centred to one of the columns supporting the overhead-crane rails. The crane just – gingerly – took enough of the milling-machine's weight for me to move it that few inches. In fact, simply rotating it round one of its holding-down screws in the concrete floor.

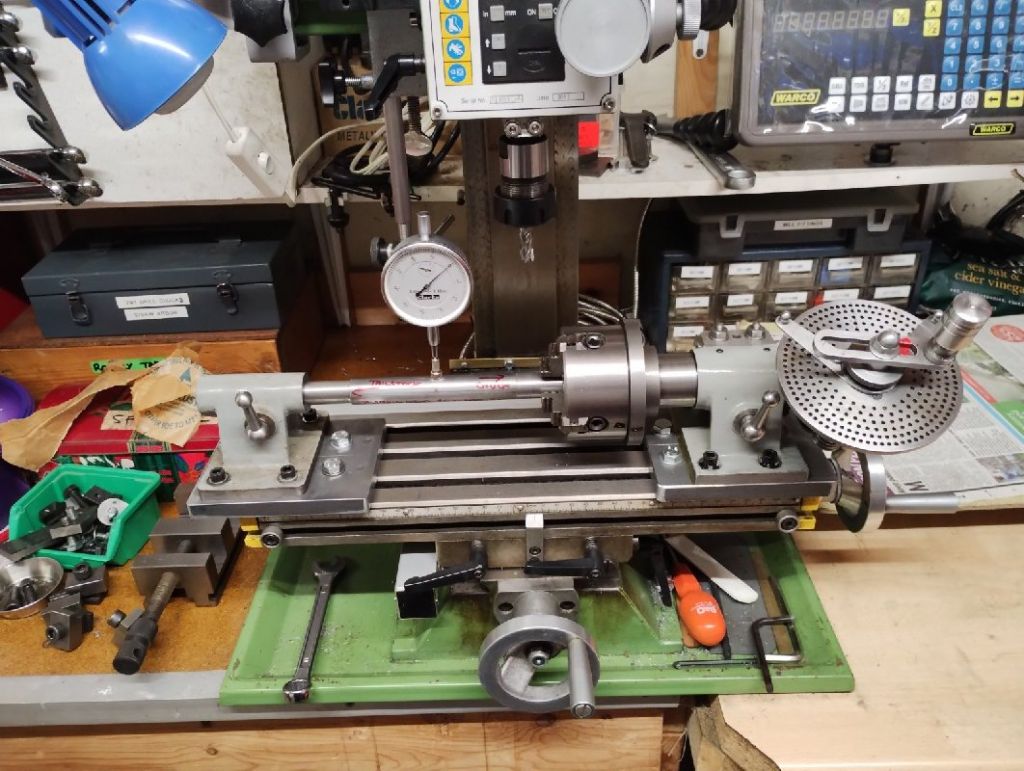

I had originally put it at an angle to the wall, parallel but rather close to the adjacent Myford vertical mill. This simple rotation does two things (apart from moving surrounding clutter to another heap):

– Greatly improves access to both mills with little conflict with the Harrison lathe opposite the Denbigh. I tested that by standing on the normal spot for using the lathe. If anything it will tend to stand me slightly further from the revolving chuck. The cranked handle for the mill's knee was jabbing me in the back so I turned it back to front, pointing inwards! If that seriously affects using it, I could make it readily removable.

– Greatly simplifies making the mounting frame for the Denbigh's overhead drive, as it is all now closely square to the wall, and I can use the crane-rail column within it.

Then time for tea.

Matt T.

of welding.

of welding.