Wow. Attitude much? It's a wonder you keep posting when things are that bad!

Criticism? Well, like such videos in general, 25 minutes of talking head waffling and tedious video of basic turning and drilling in the lathe and we get to the end and …. it's not finished yet! And we still don't know what the finished product looks like, and thus whether or not we might like to make one. "Wait for part two." You have got to be kidding. All this time invested — 25 minutes so far — to find out how you made a carriage stop, when the very simple concept could be grasped in 2.5 seconds via a photo or drawing of the finished item.

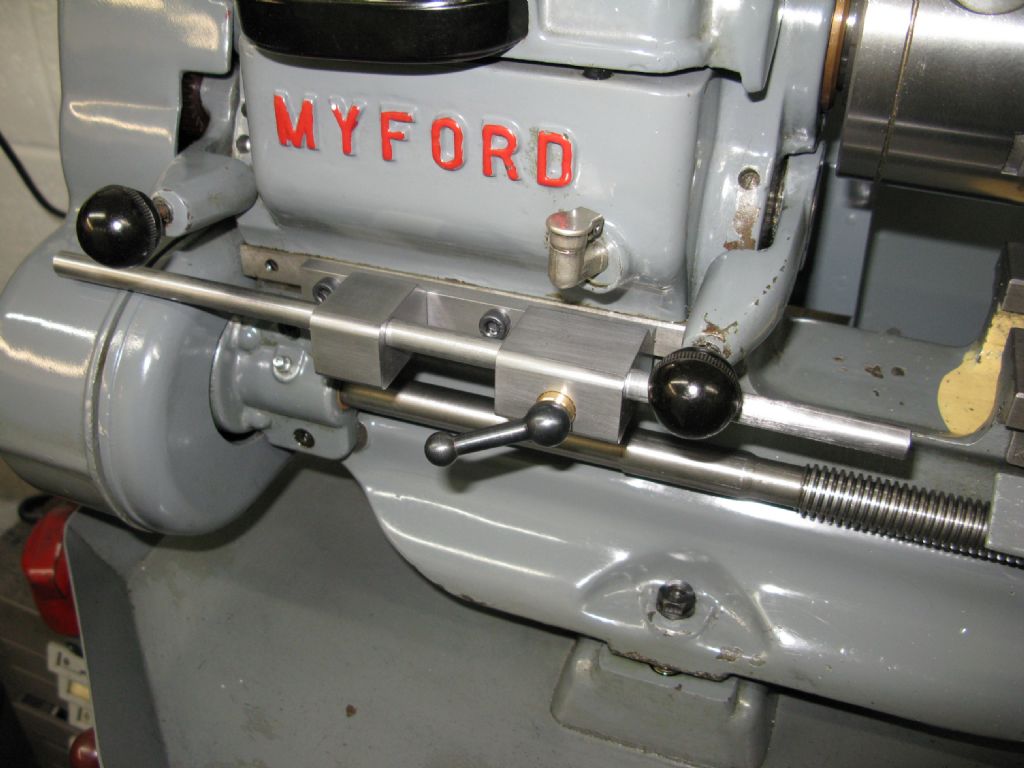

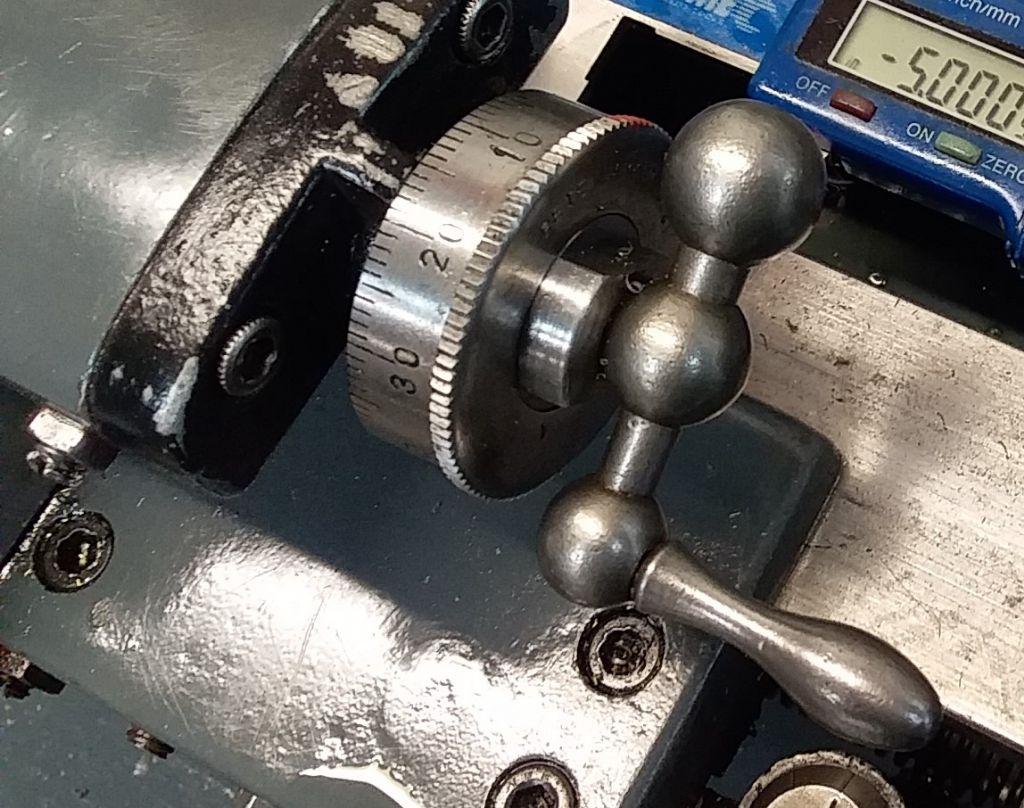

Here is the Myford carriage stop I made a few weeks ago, used for putting the calibration marks on a resettable cross slide dial I was making. The first pic of the basic "makings" showing the basic principle. Second photo showing the finished item after "tarting up". 2.5 seconds to grasp the basic principles and see how to make your own very simple version.

Technical details:

- Made from a bit of 20mm x 50mm flat bar about 75mm long. A 5/16" hole drilled lengthways for the piece of 5/16" threaded rod to pass through. Three nuts used to set position as shown.

- Two holes drilled and counterbored crossways to fit 1/4" BSF socket head cap screws. Screwed into one existing gearbox mount hole in the bed. Second hole spot drilled through the stop body and tapped 1/4 BSF to suit.

- Bit of brass hex bar turned and threaded to fit on the end so it's a bit kinder to the carriage where it hits.

- Shaped body on belt sander to make it look like an original casting.

- Painted with Bunning's cheapest Machinery Grey rattle can.

- Further extensions can be screwed on by replacing the brass hex with a builider's 5/16 joining nut, used to join two lenghts of threaded rod together when hanging suspended ceilings etc. Stop can be set all way to the left out of the way when not in use.

- End of.

Some basic story telling tips from a media professional that apply to making videos:

Start with a pic or video of the finished project so people know what we are talking about and where we are heading. A video of the piece in action is better than one of it just sitting there.

Keep talking head footage to an absolute minimum. Boring. Very, very briefly introduce yourself, then get the hell out of the way!

Stay on task. Have a prepared script and stick to it. No waffling on about stickers on the wall or side issues. Look at the way TV news reporters do their voice-overs, modulating their voice as they go and combining the voice with footage of the actual event/job going on.

Limit footage of mundane machining operations. We all know what it looks like to take a cut all the way along a 6" long piece of half inch bar, or to drill a hole all the way down the middle of it. It's the machining equivalent of watching paint dry. Instead, use editing software to show the start and basic set up of the machining and either show fast motion machining or cut straight to the end of the cut and show the finished result.

Do show details of any particularly unusual, special or tricky set ups and procedures, but again not going on and on in real time. Show the set up, the basic process, then cut to the end result.

Then at the end show it all being assembled and finally being used. Back to where you started in the opening scene of the finished item in use. In the trade, that is known as a "closer". Watch TV current affairs shows etc for this commonly used technique. It's ubiquitous.

We live in a fast paced world, and the net is even faster. Viewers want a quick take, not War and Peace.

Well, you did say you like criticism! And videos that take hours to convey minutes' worth of information are a pet peeve of mine. Apart from the fact that so many of them on machining are laughably wrong, made by relative beginners blissfully unaware of the clangers they are dropping. Here's a favourite of mine from the usually very good BlondieHacks. Have a look at the 6:30 minute mark involving a fixed steady and dial indicator, and you tell me what's wrong with that.

Edited By Hopper on 20/02/2022 04:15:13

Edited By Hopper on 20/02/2022 04:25:23

Edited By Hopper on 20/02/2022 04:30:42

Edited By Hopper on 20/02/2022 04:38:05

Hopper.