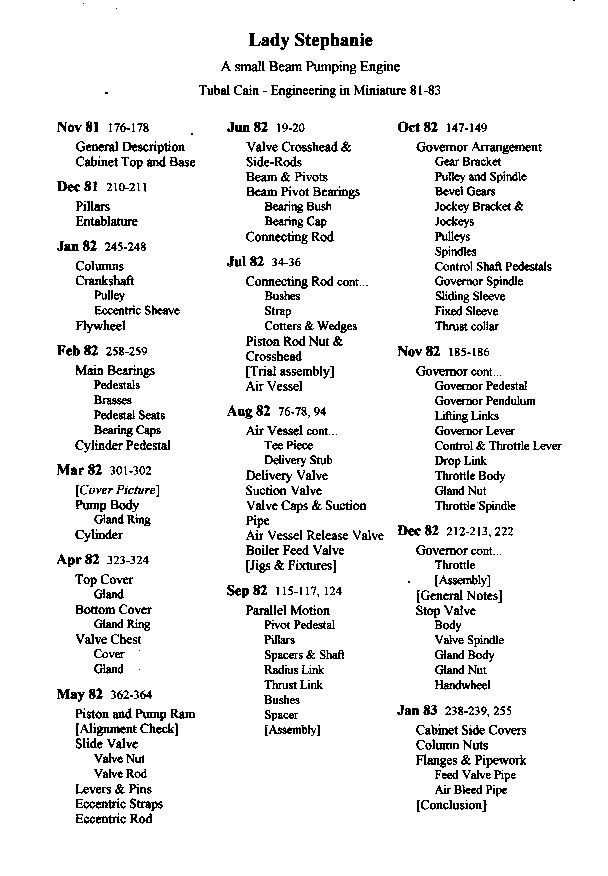

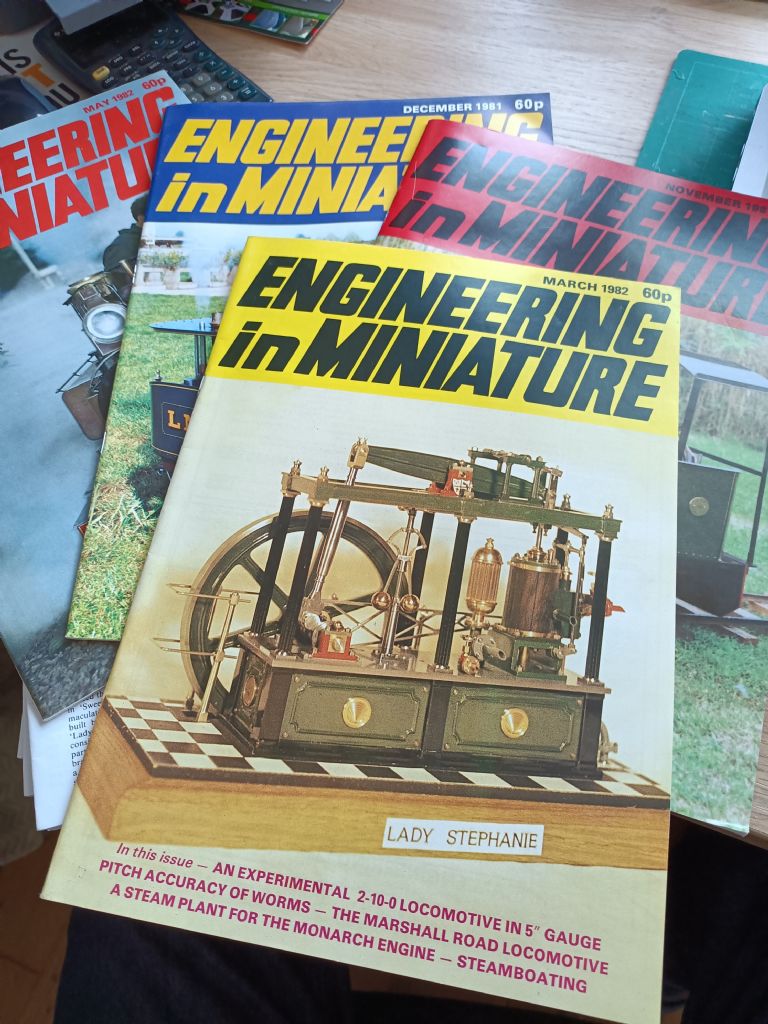

Having my workshop settled I need to build something. Well that's a lie, I started already during the Christmas holidays… But now I have no excuse.

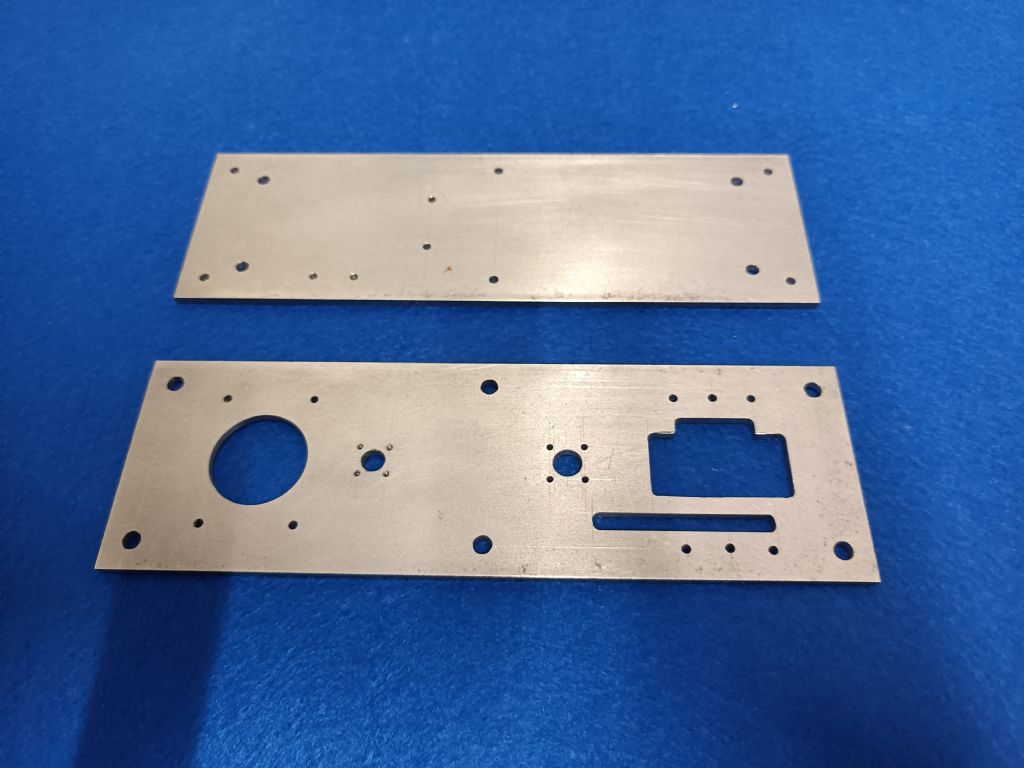

Unfortunately I do not have any building description, but the plans should do it. So I thought I start with the frame. I tried to get enough material to repeat every part minimum once. Good decision as we will see at the second picture.

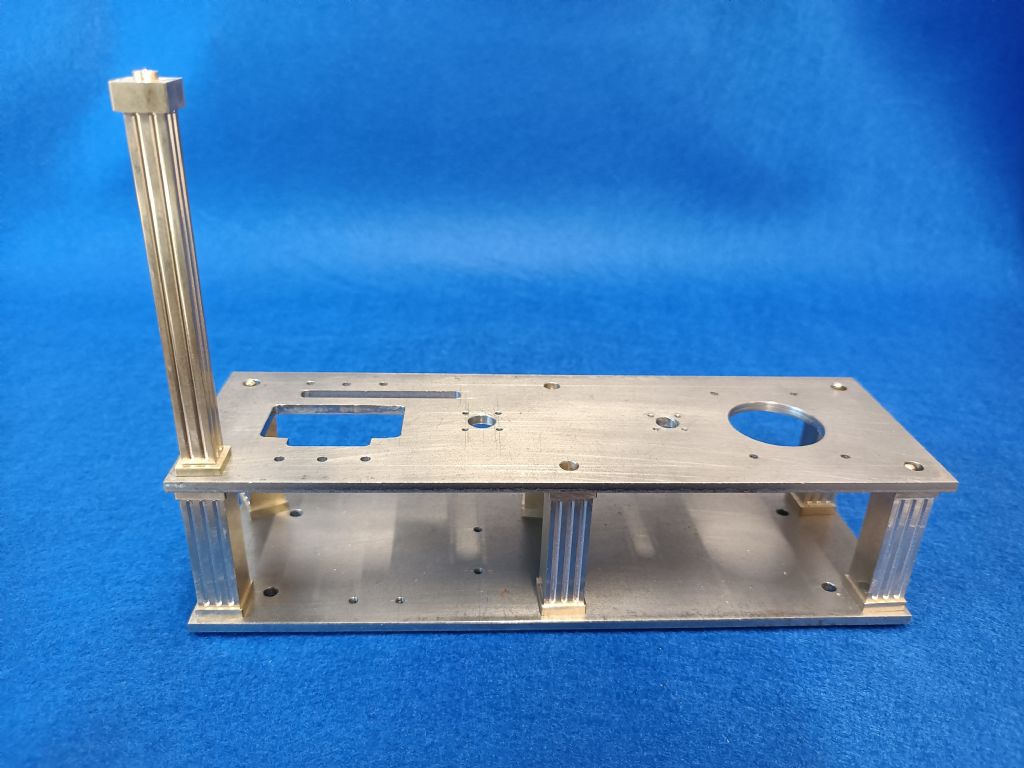

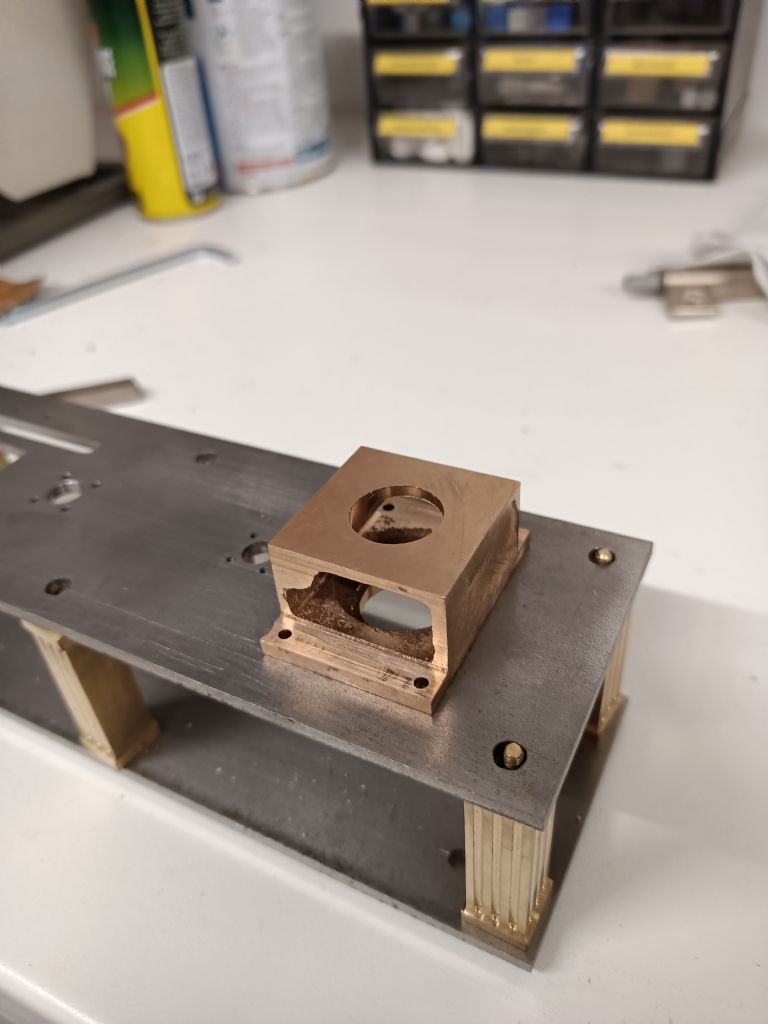

I was happy with the precision of the opening for the cylinder pedestal.

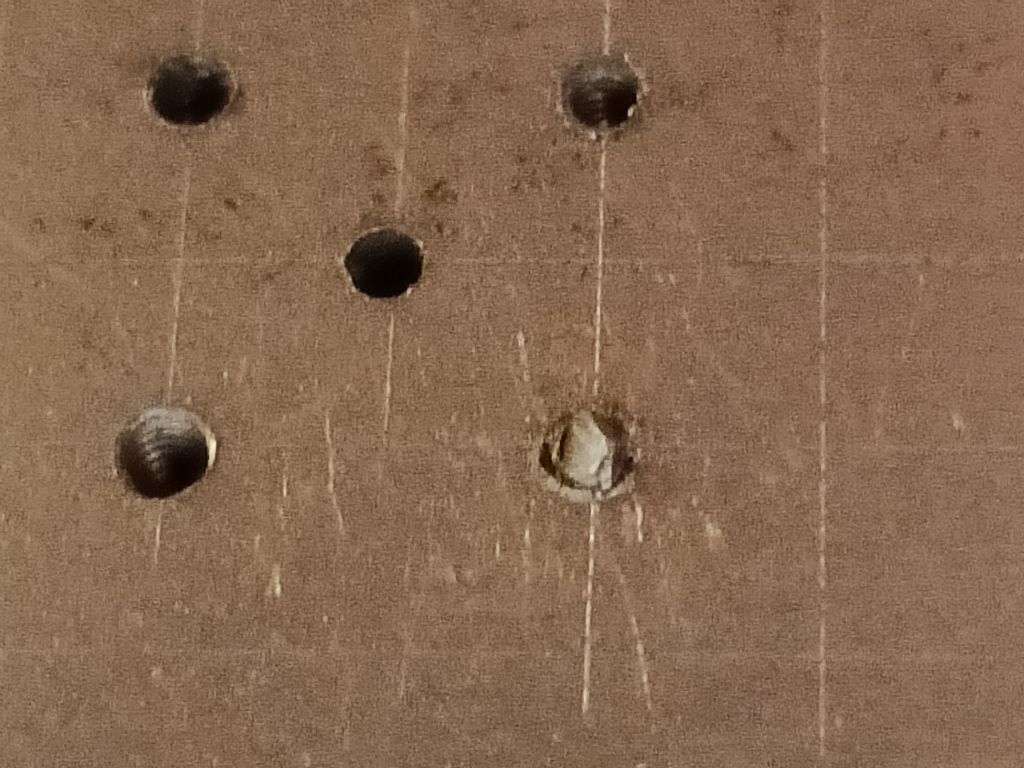

This didn't last long, it is quite tricky to cut small threads into thick mild steel.

Here we go, one tap less. And no chance to get it out… By the way it was M1.6, I have a good collection of metric taps and dies, so the lady will be a little bit 'metricized'. I hope she doesn't mind.

Anyway. Another go. This time right. Cabinet base and cabinet top done.

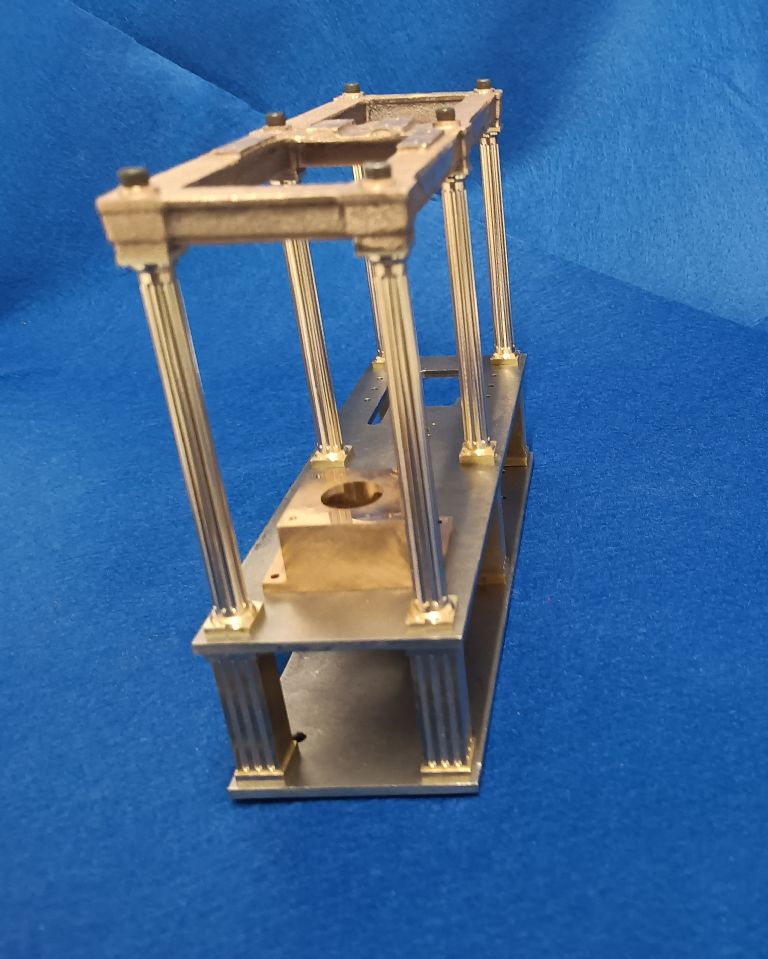

Now it is time for a bit of bling, lower columns.

Also here I was using the spare one, as I ruined the first one by cutting in the flutes. Because of the removal of my machines into my new garage workshop (good bye cold shed, now I have a massive radiator plumbed into the central heating which costs less than the shed heating and doesn't produce water vapour) I had to remove one of the DRO sensors – and I didn.t fix it properly. Means I got some play which ruined my flutes…

Finally I am playing now with the upper columns. I am not sure if I make them round and tapered or square. I started with the square one, as I still had the mill set up nicely for that from the work on the lower columns.

And in the next pictures you can see the outcome.

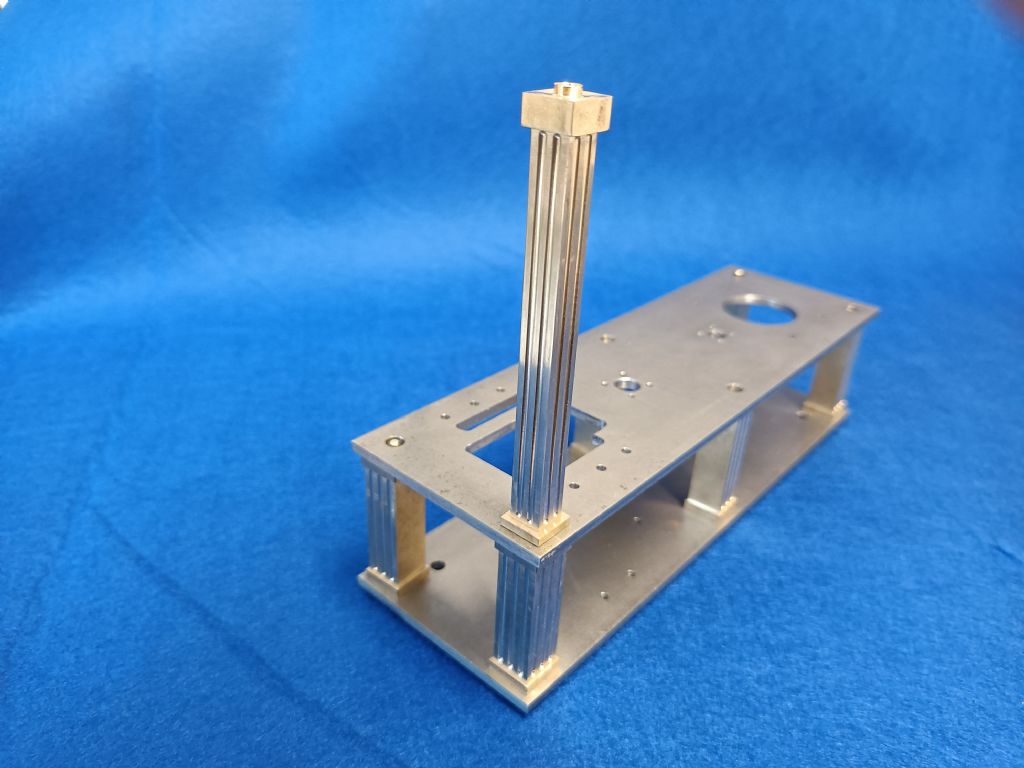

I think I tricked my phone with the blue background, as the columns are brass. in these photos they look rather like steel.

Yes – this is where I am at the moment, I will give you an update from time to time.

Happy modelling!

Edited By Gerhard Novak on 13/02/2022 16:13:20

alan ord 2.

alan ord 2.