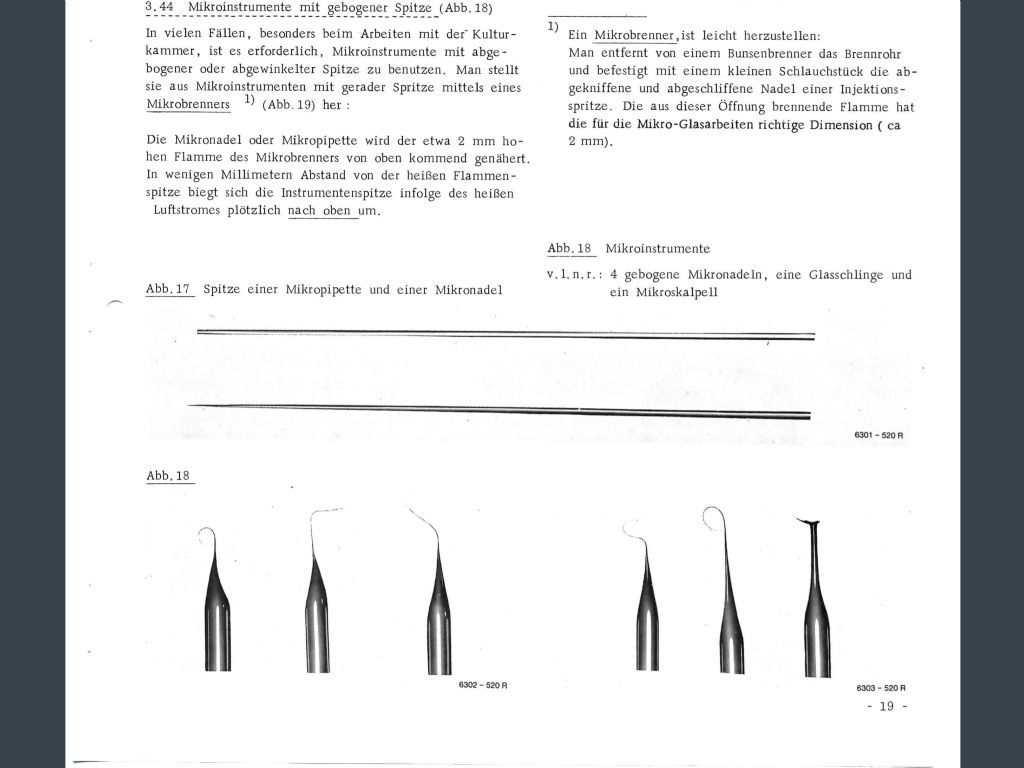

Posted by Martin Whittle on 23/08/2017 08:47:28:

I have some difficulty in seeing how an air inlet can be created.

In a bunsen burner, the jet is used to restrict the flow of gas and to create a jet of gas which sucks air into the airhole.

Without re-jetting the burner, the flow will be restricted by the needle, not the jet, Therefore the pressure lower down in the needle will be above atmospheric, and not below: therefore gas would escape via the 'airhole', rather than air coming in.

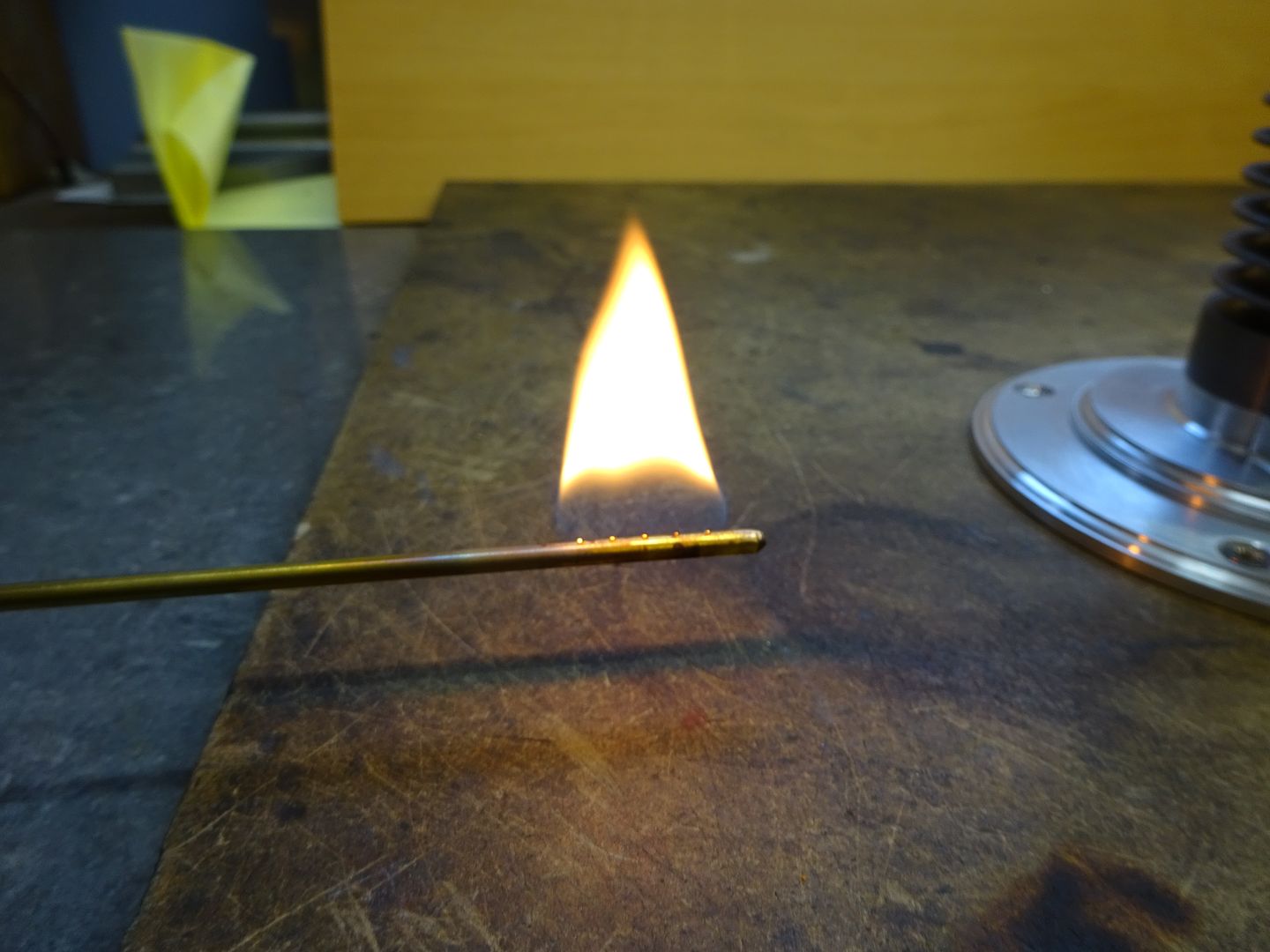

Maybe with a very small fast flame, it will burn efficiently without an airhole?

NB could be best to use a dispensing needle (not sharp and cut straight across the end), not a hypodermic needle, unless the taper of the needle end is beneficial in terms of mixing air into the gas – would abrading/reshaping the tip help?

Edited By Martin Whittle on 23/08/2017 08:48:04

I'd agree with that.

My own impression is that:

i) Google's algorithm looked for an existing translation first before trying to do it itself, and found one, and

ii) whoever wrote the original was guessing, and hadn't actually made the equipment.

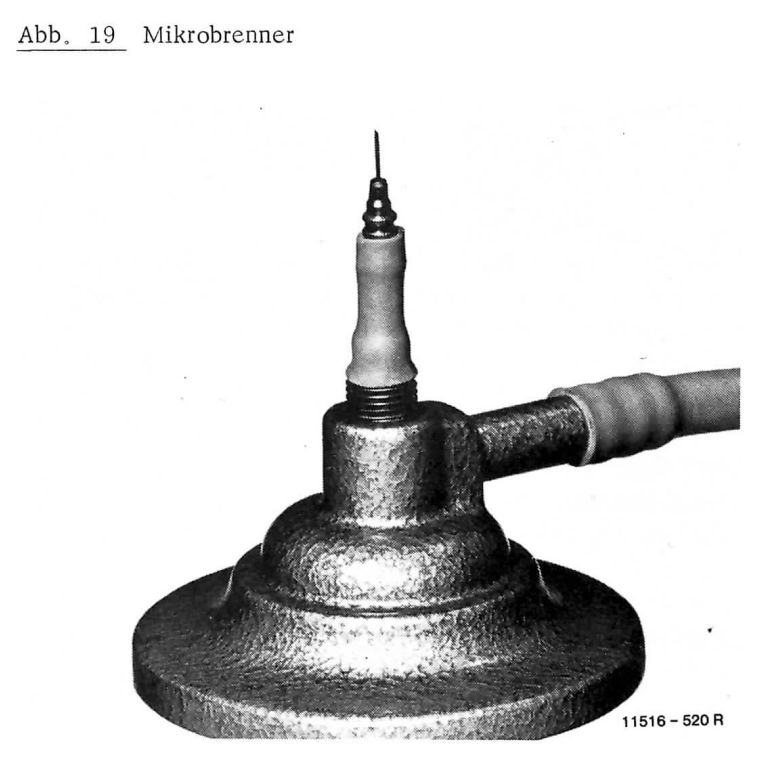

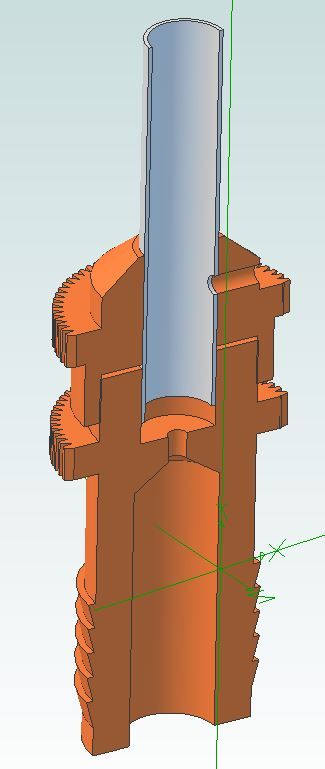

Mind you, I ain't done it neither – but what I'd suggest is using the needle tube from an inkjet-cartridge refilling syringe (or suchlike) as the mixing/burner tube, with part of a fine hypodermic needle as the jet. Then make a sleeve with an airhole to fit over the burner tube. I think there'd be a fair bit of watchmaker-fine engineering to do to fit this lot together, with a number of different possible solutions, but in principle it's a miniaturised Bunsen.

A Google search for micro bunsen produces a few options, but most look a bit too big or otherwise iffy for a 2mm flame.

Edited By Mick B1 on 23/08/2017 09:38:42

Michael Gilligan.

Michael Gilligan.

or just pop down to local agri feed/general supplies merchant who sells them in small numbers.

or just pop down to local agri feed/general supplies merchant who sells them in small numbers.