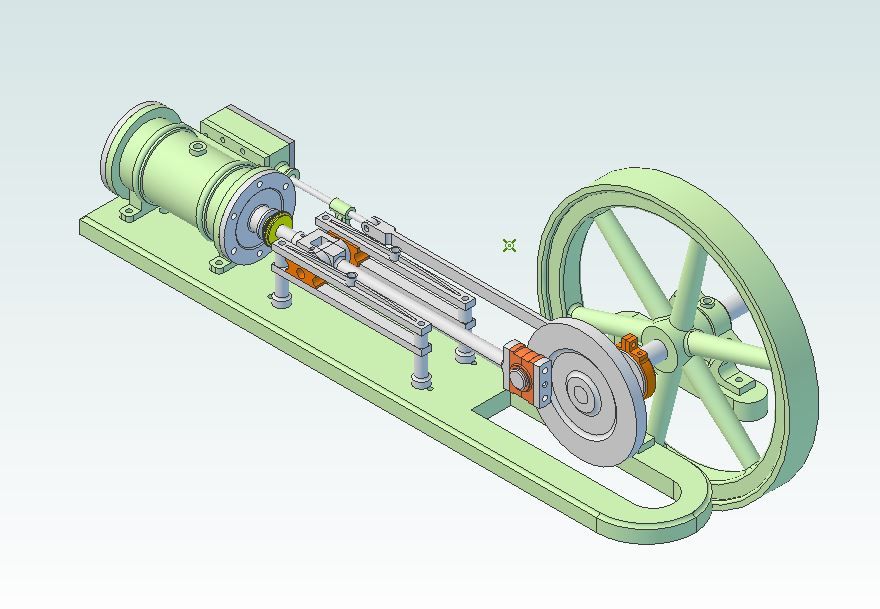

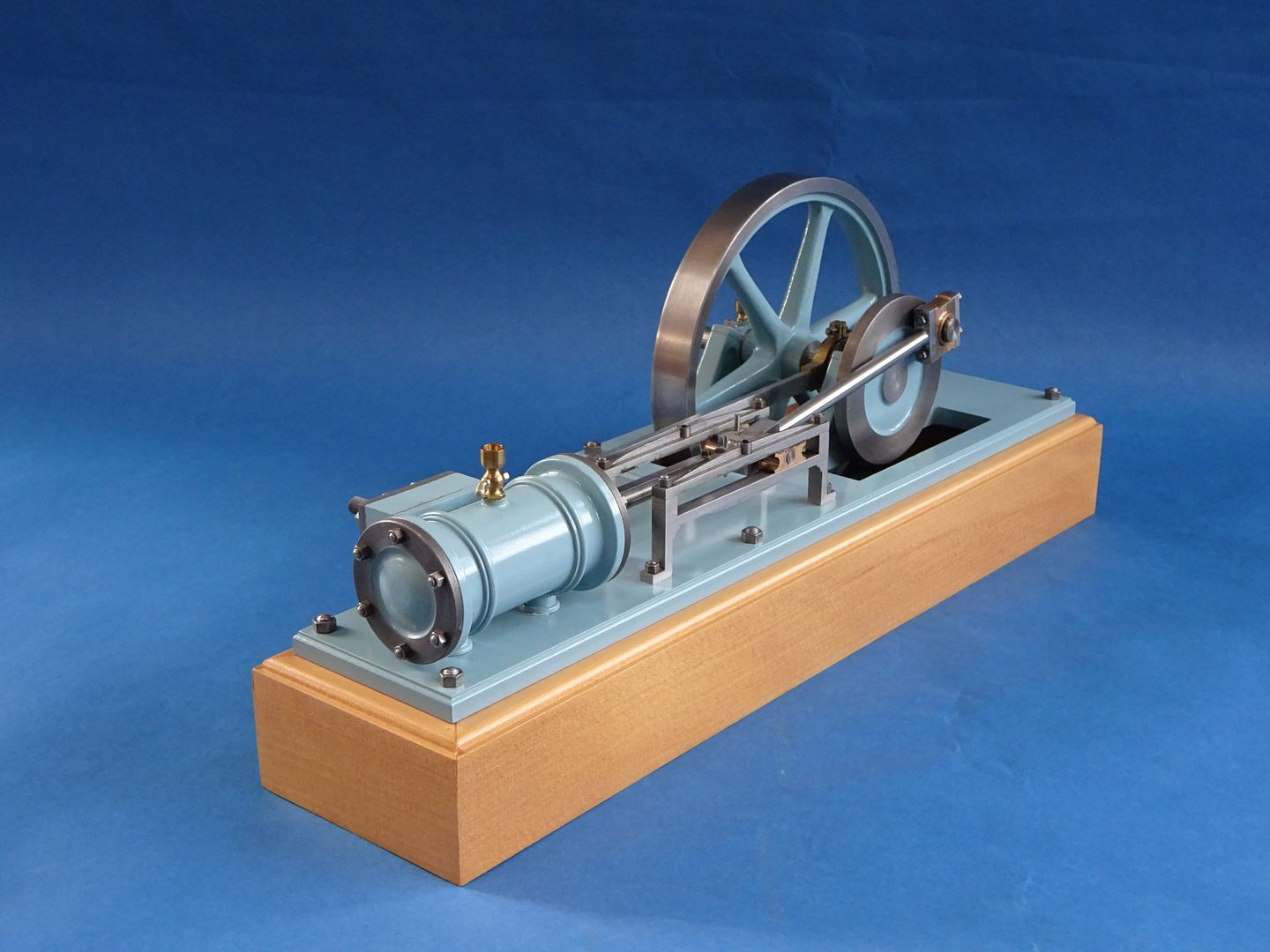

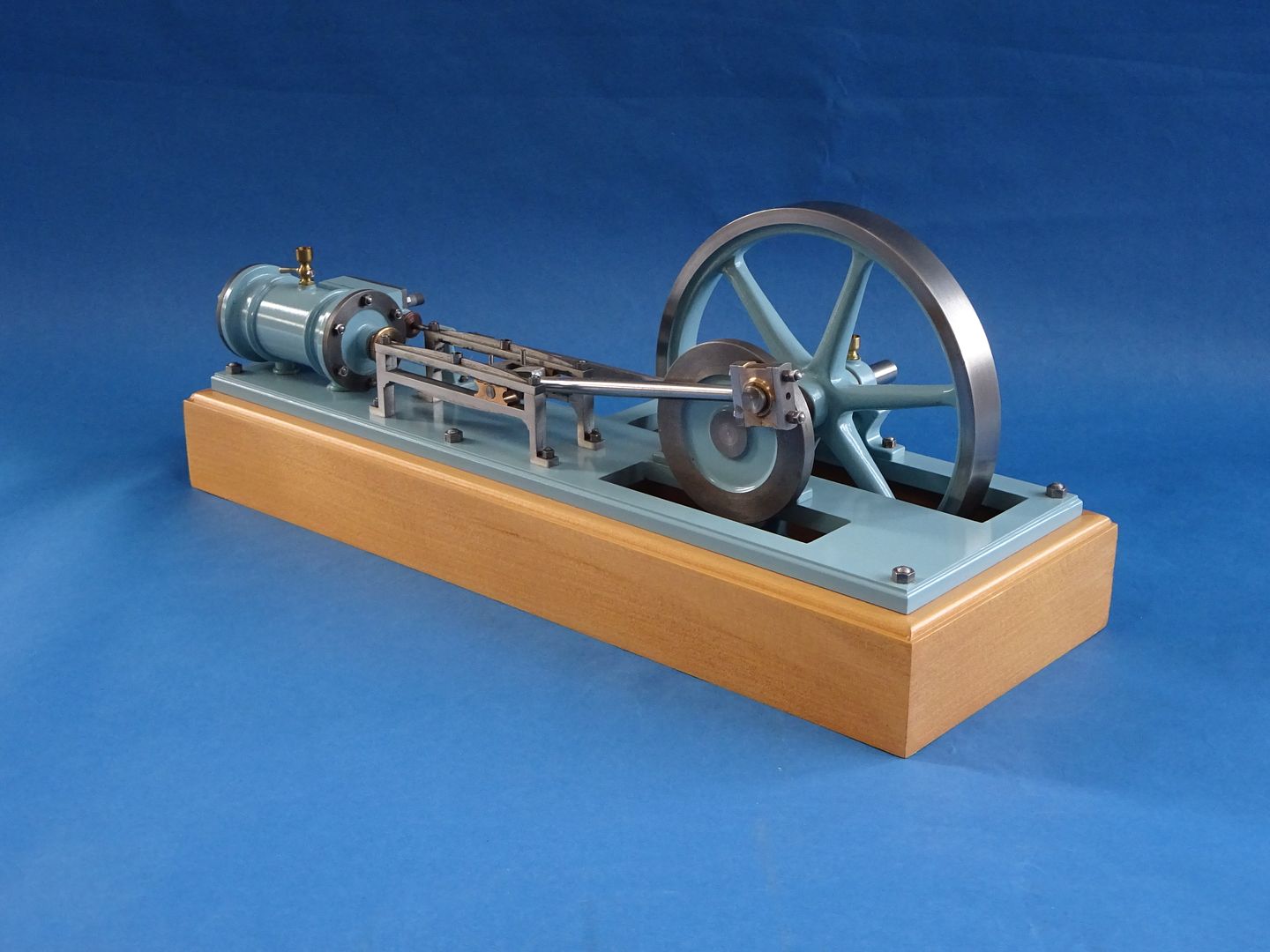

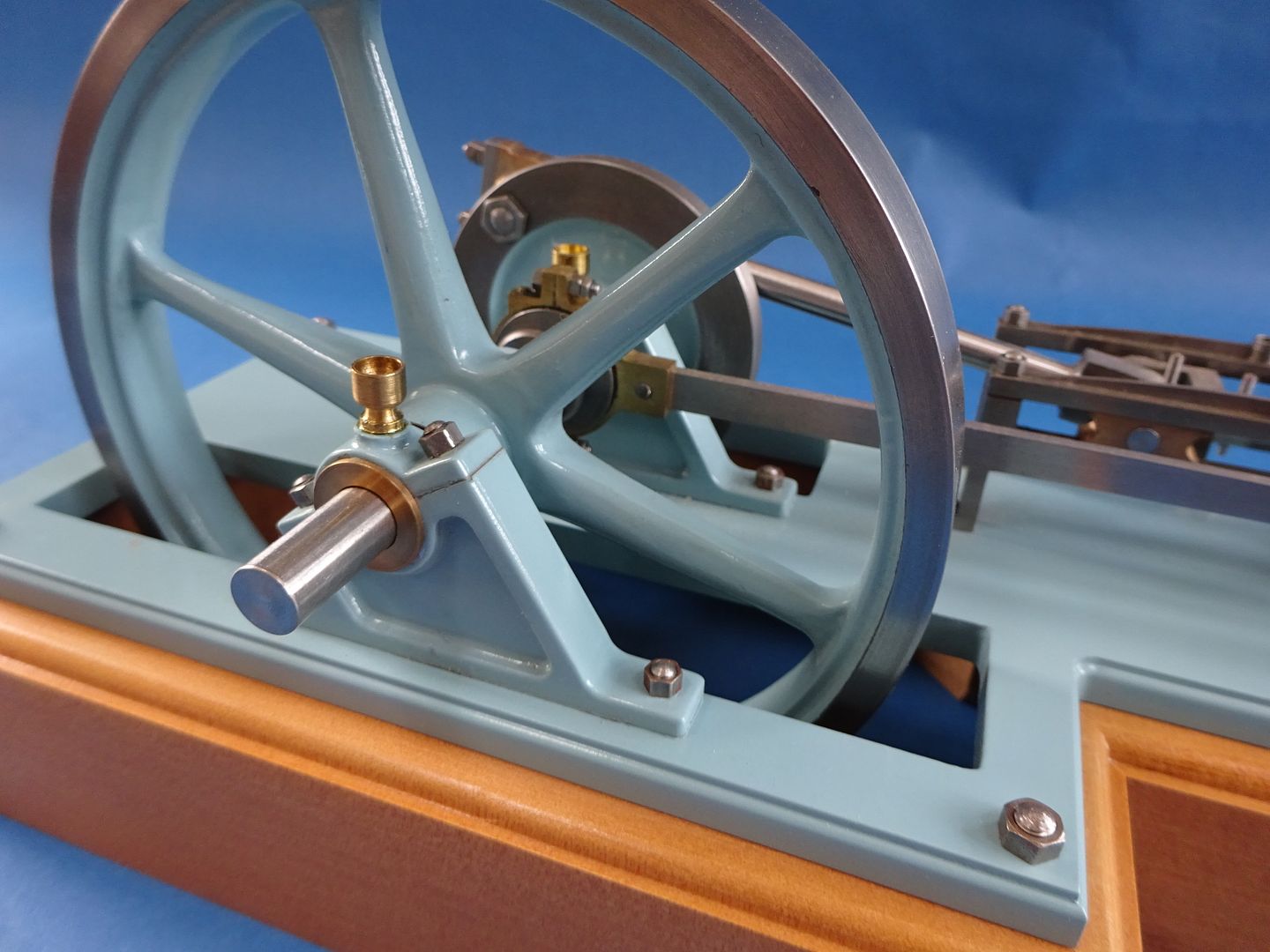

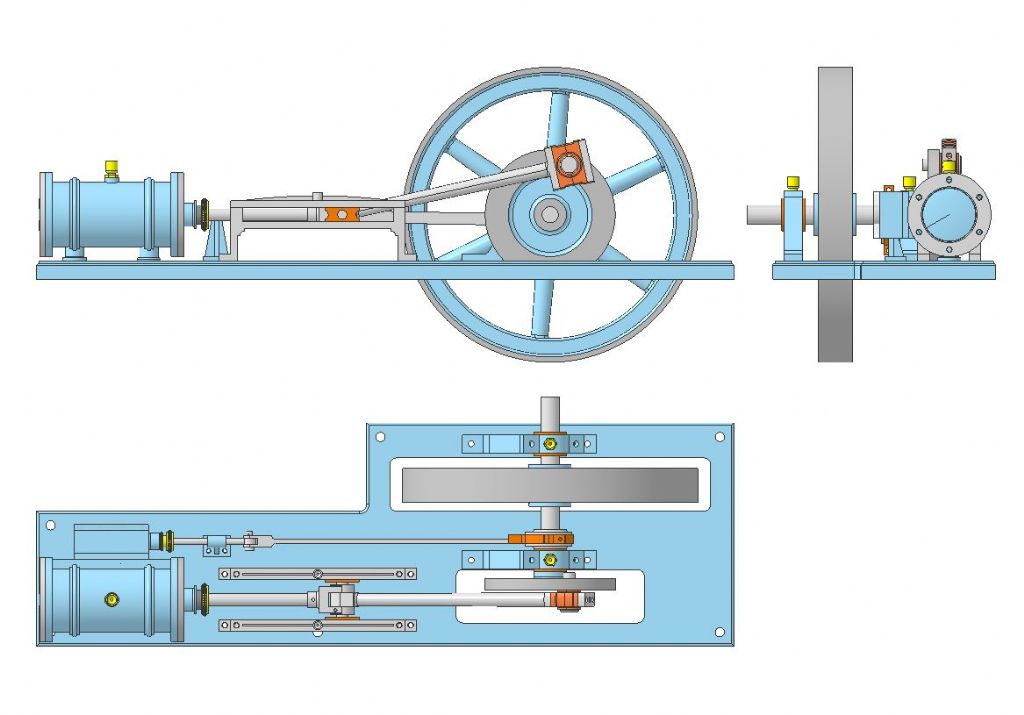

A handsome engine!

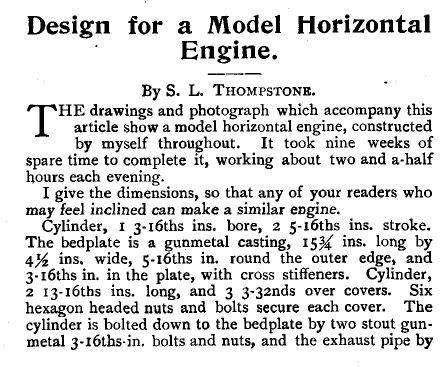

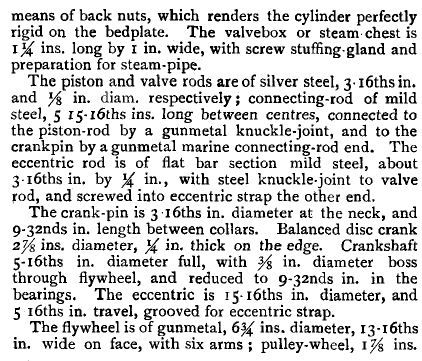

Paul – though freelance this design is very much in the spirit of any number of small horizontal and vertical engines produced by any number of companies in the late-19 – early 20C; ranging in power down to about 1HP.

Though often called "mill-engines" they were the ubiquitous industrial prime-movers of their day, for all manner of applications. Some of the small ones were portable power-packs, combining an inverted-vertical (cylinder at the top) engine with a vertical boiler, on a rather crude horse- or man- pulled trolley. Their buyers were typically farmers, builders, timber-merchants, quarriers and the like.

A horizontal stationary-engine of the genre, probably around 10NHP rating and built by Hindley for driving water-supply pumps, is preserved in running order in the waterworks museum at Sherborne, N. Dorset; open on some Summer weekends. Other examples in different forms are to be seen at Weston Zoyland [fenland] Pumping Station.

'

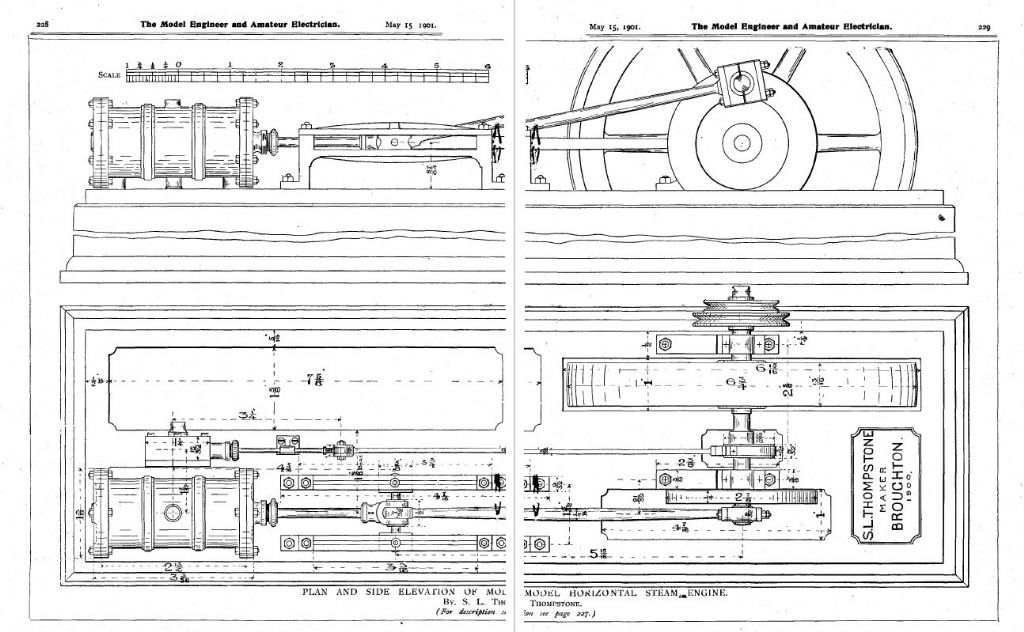

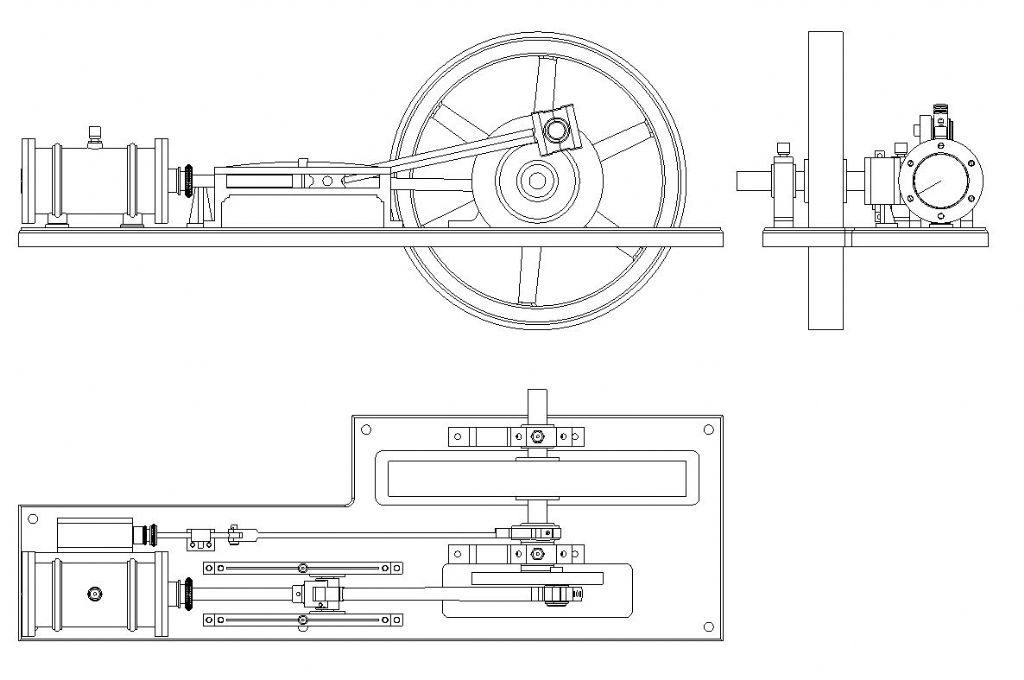

Ron's query: Bore : Stroke = almost 1 : 2. Thompstone had it right, typical for such horizontal and vertical engines, according to a book I have published in 1911. The table is for "Strong" engines from 3 to 30 Nominal Horsepower.

By the same table, a short-stroke "Light" version (1.5 – 16 NHP) was commonly over-square, about 1 : 0.8 . I am not sure what the adjectives meant in this context!

'

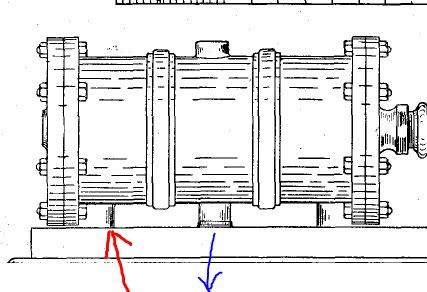

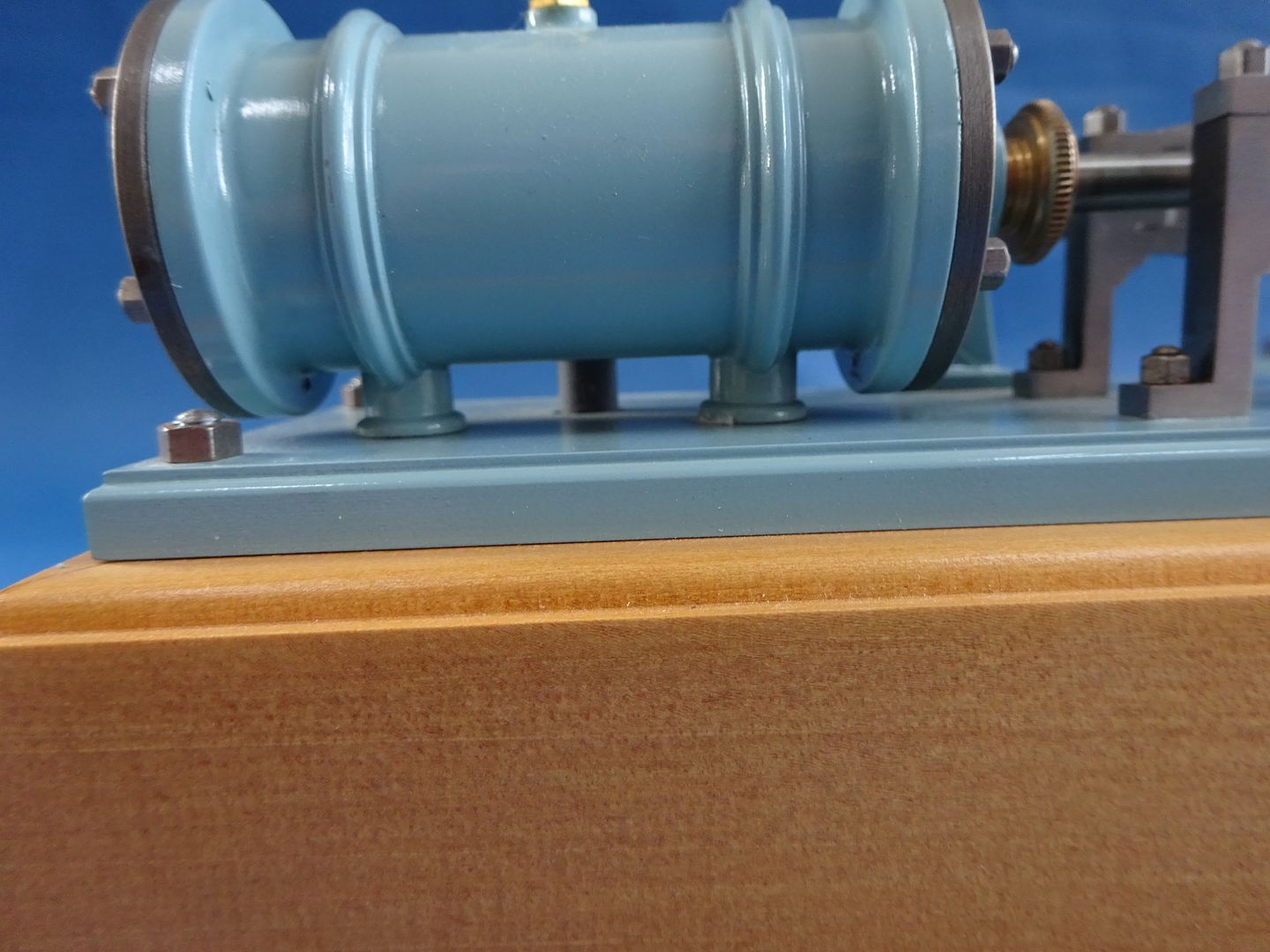

My query – The rings round the cylinder were common practice so look right here, but I wonder if they were purely "ornamental" or also functional in some way – reinforcing perhaps, to support cladding where fitted, or to prevent cracking from the contraction stresses in cooling.

(The curly spokes on some cast wheels was not prettiness but that anti-cracking precaution.)

Some engines were quite highly ornamented – think of the giant beam-engines at Kew for example- but that would have added to the manufacturing cost. Still, places like Kew Bridge Pumping Station were among the prestige public-service projects of their day, so designers reflected that. Would it have been done for more modest machines though, more impressive in looks than are electric motors, but doing essentially the same thing?

Anyway, it's a very elegant design, good to see revived.

Edited By Nigel Graham 2 on 17/04/2021 11:41:28

paul rayner.

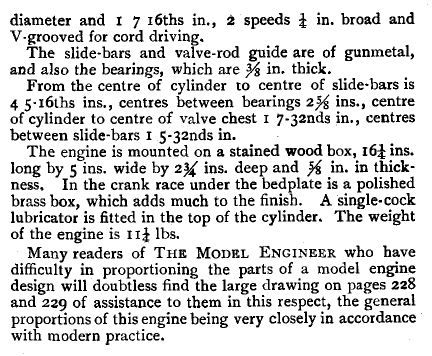

![20210407_141447[1].jpg 20210407_141447[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/892023.jpg)