Posted by not done it yet on 16/02/2023 22:37:05:

300V Would be my guess. These are to suppress sperks – and you don’g get sparks like these at low voltage, as it is the induced back-emf from the coil windings.

It's the sort of question that hurts my brain. If the capacitor is left out, the back-emf rises rapidly and the coil generates a voltage spike – certainly hundreds of volts. The energy is wasted because it sparks across the distributor contacts rather than where it's needed at the spark plug, and it soon erodes the contacts. Not having a capacitor is bad!

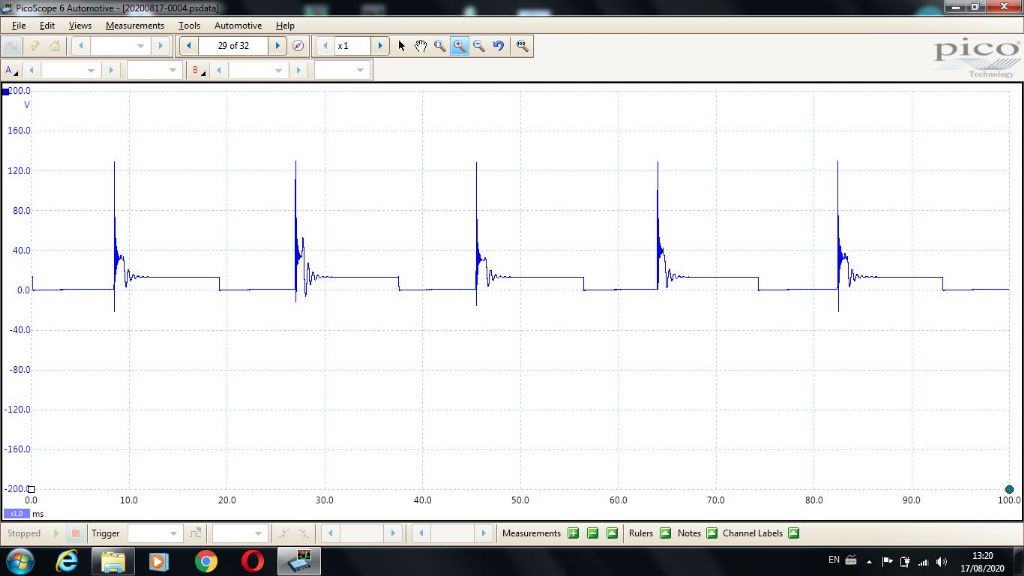

However, when a capacitor is fitted, it absorbs the back-emf by charging up and prevents the voltage rising anywhere near spark voltage level. To a voltage spike, the capacitor looks like a dead short. How high the voltage rises as the capacitor charges when the breaker opens is beyond my understanding, but I guess it's closer to 12V than 120V. *** Edit: Posted before Maurice's reply above, where his oscilloscope shows a 120V peak on the capacitor. The capacitor has to be rated to take that, so I now say 200V.*** If the capacitor is too small, the voltage will rise higher, causing sparks and risking popping the capacitor. If the capacitor is too big, it will smooth out contact breaker action so much that the coil won't fire.

In a common sense way the action of a capacitor is simple: one of roughly the right size, about 0.1uF, makes the engine go better, the contacts last longer, and you can hear the radio! Seems simple to us but it took about 30 years of research early in the last century to get right.

How a capacitor really works is more difficult in this application because the designer has to size it to compensate for several rate of change effects: how fast the engine is turning, how quickly the contact breaker opens, how long it takes the ignition coil to charge and discharge, and how stiff the power supply is.

The chosen value is a compromise, one that allows the engine to perform reasonably well between, say, 800 and 3000rpm. Unfortunately, no matter how well made, an ignition system combining condenser, distributor, contact breaker, and coil is never optimum. For that reason modern cars now use electronic systems that can vary timing on the fly and have no contact breaker, distributor or capacitor. The deliver better starting, fuel-economy, performance, and less pollution. An engine management unit replaces the vacuum adjuster and provides timing accurately tuned to rpm and load as they change on the road. Much more reliable too. On the downside, they're far harder to understand and fix. No skilful mechanics adjusting the breaker with a bit of fag paper, the garage has to connect the car to a diagnostic unit…

Dave

Edited By SillyOldDuffer on 17/02/2023 10:15:18

Edited By SillyOldDuffer on 17/02/2023 10:22:47

SillyOldDuffer.