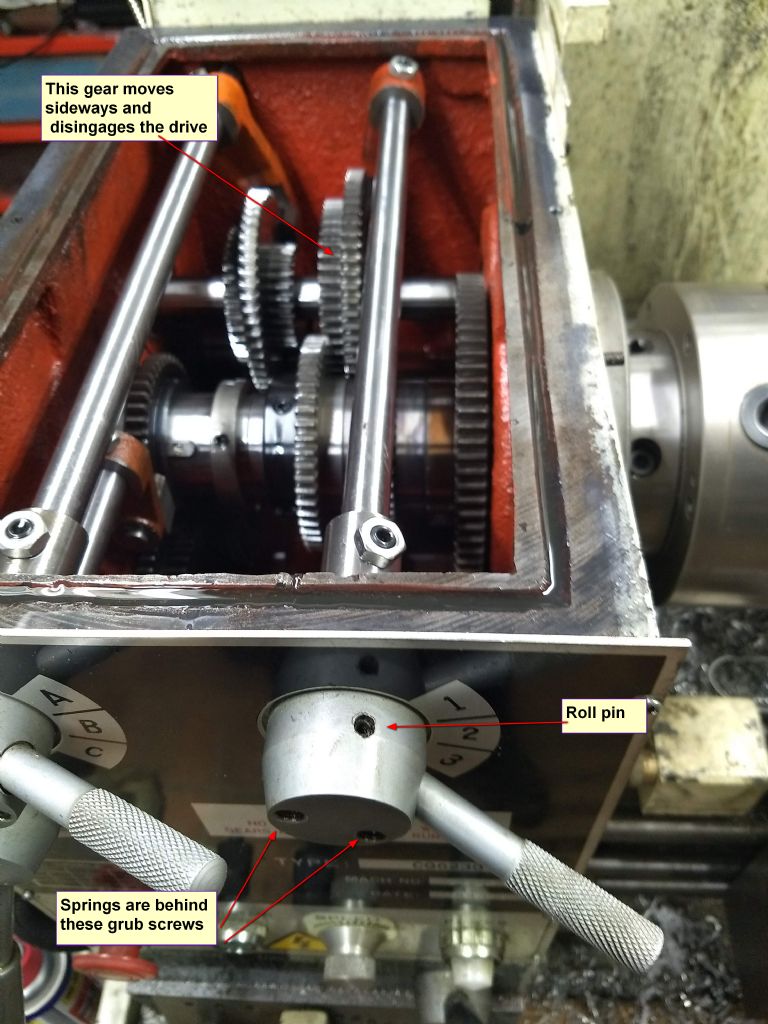

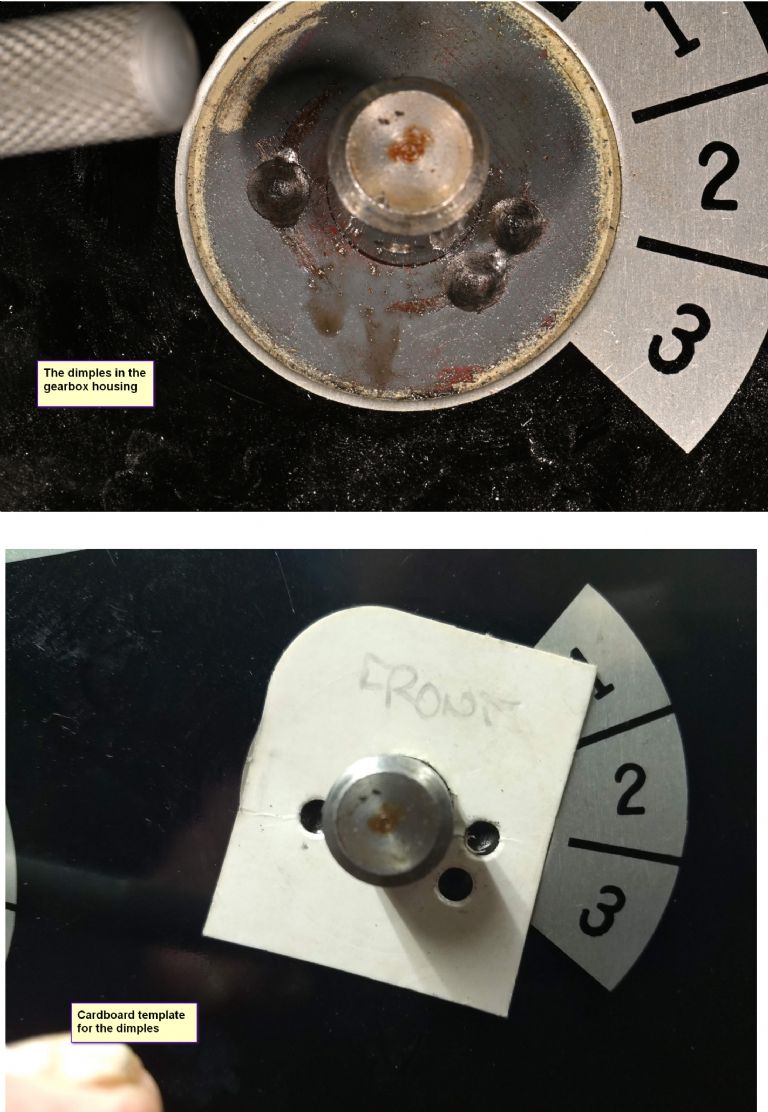

I've investigated much closer. I removed the grub-screws, springs, and balls from the selector knob and removed the knob from the shaft. Neither the springs nor the balls showed any signs of damage or wear. The detents in the gear housing also looked fine. I made a cardboard template that fitted on the selector shaft and contained holes that revealed the detents in the housing. The following photos shows the detents and the cardboard template.

I also took a photo of the selector knob showing the positions of the holes for the two spring loaded balls.

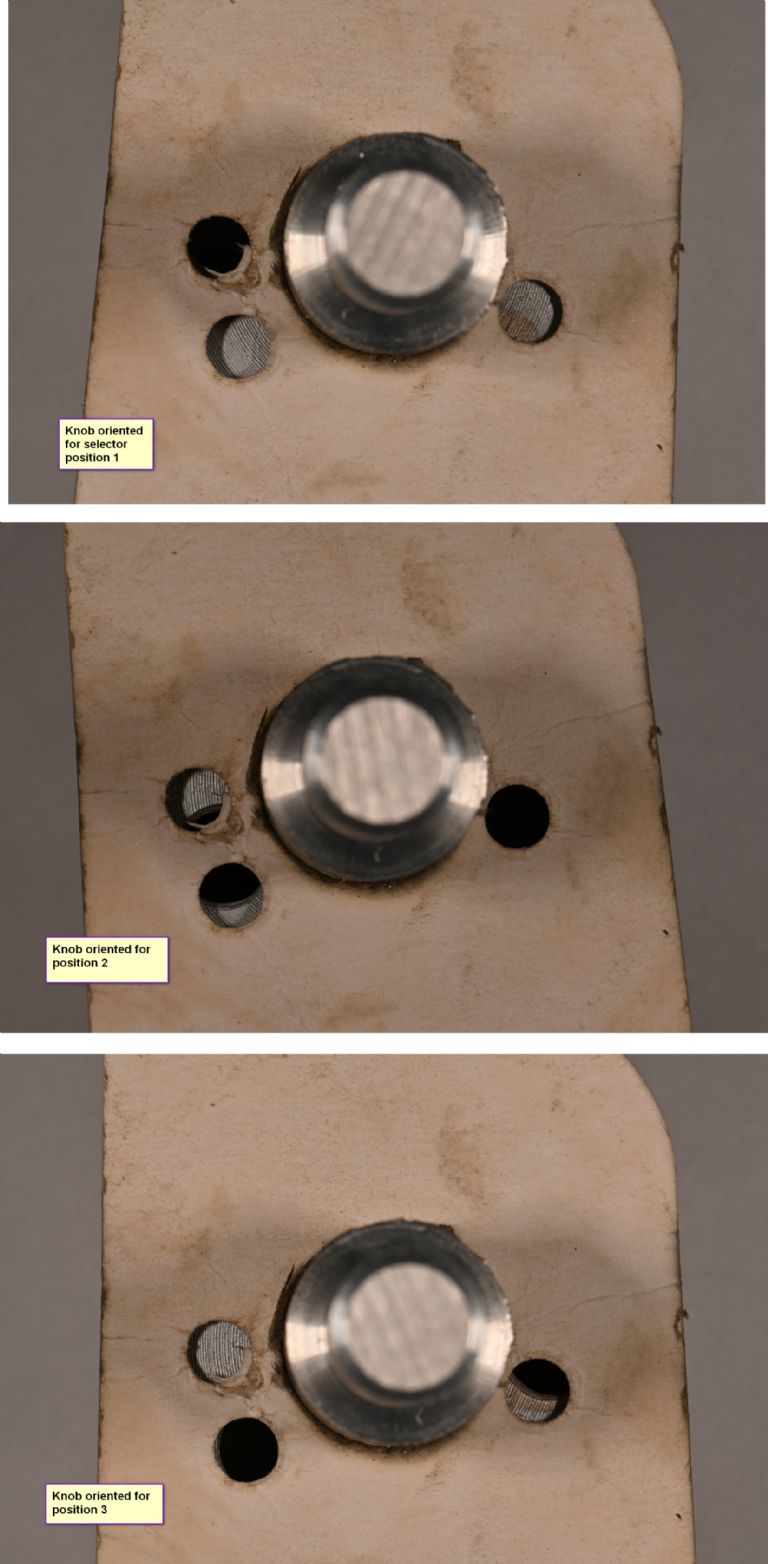

I then found a short length of bar that fitted into the rear of the selector knob, and positioned the cardboard template on it to give a view as if looking from within the gearbox, outwards to the rear of the in-place selector knob. The three holes in the template representing the the three detents. I was then able to see how the detents aligned with the balls when the knob was rotated in its three positions.

I position 1, the detent at 9 o'clock lines up nicely with the hole in the knob. In position 2, the detent at 3 o'clock lines up nicely, but in position 3, when the detent at 8 o'clock is aligned with the knob hole, the 3 o'clock detent is nearly aligned with the other knob hole, which has the effect of both detents trying to align the shaft.

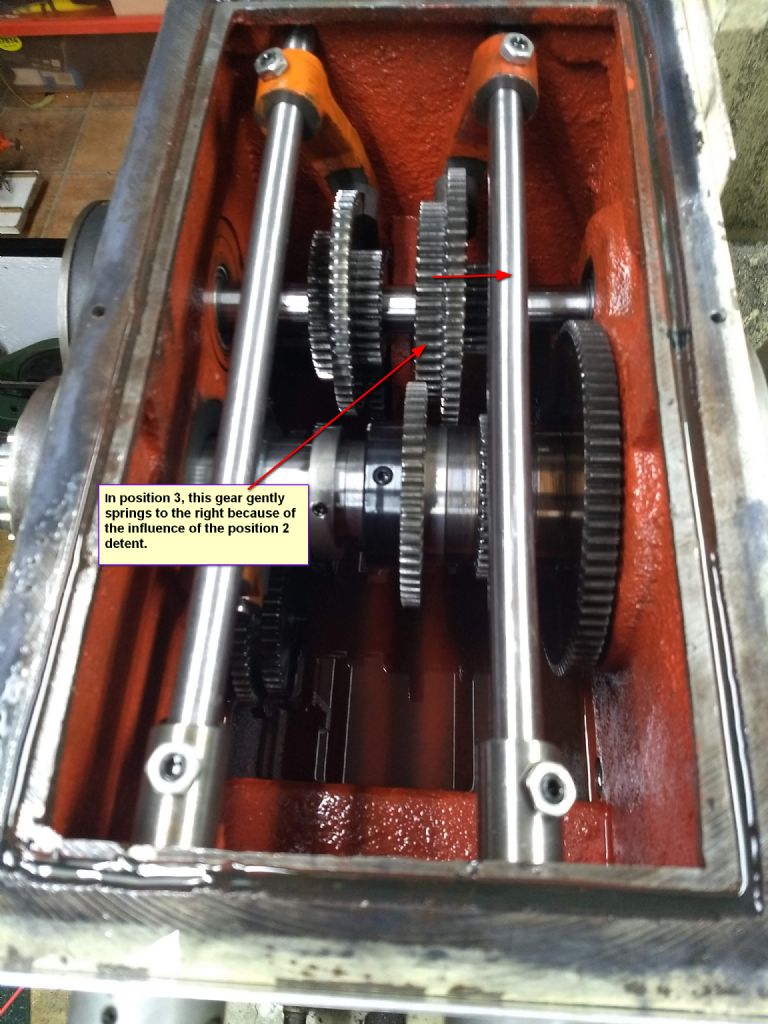

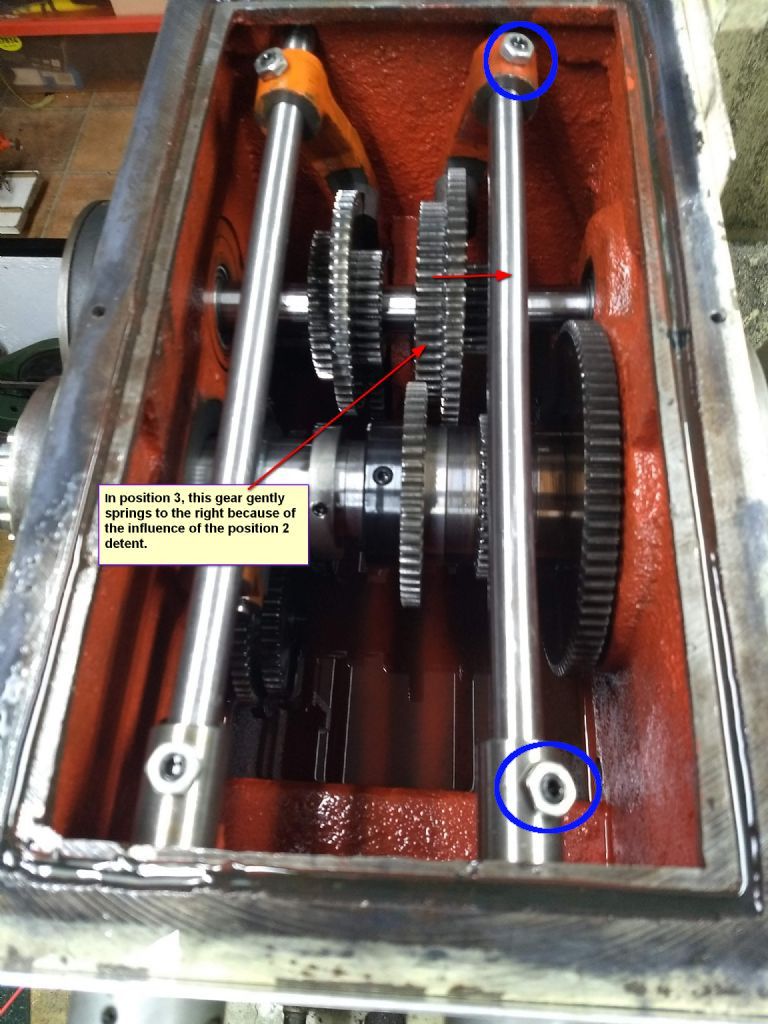

Because of this slight misalignment, the gear in the following picture gently drifts to the right.

Seems like a manufacturing fault to me. In the meantime I intend to adjust the fork to the best compromised position. Any ideas about a solution?

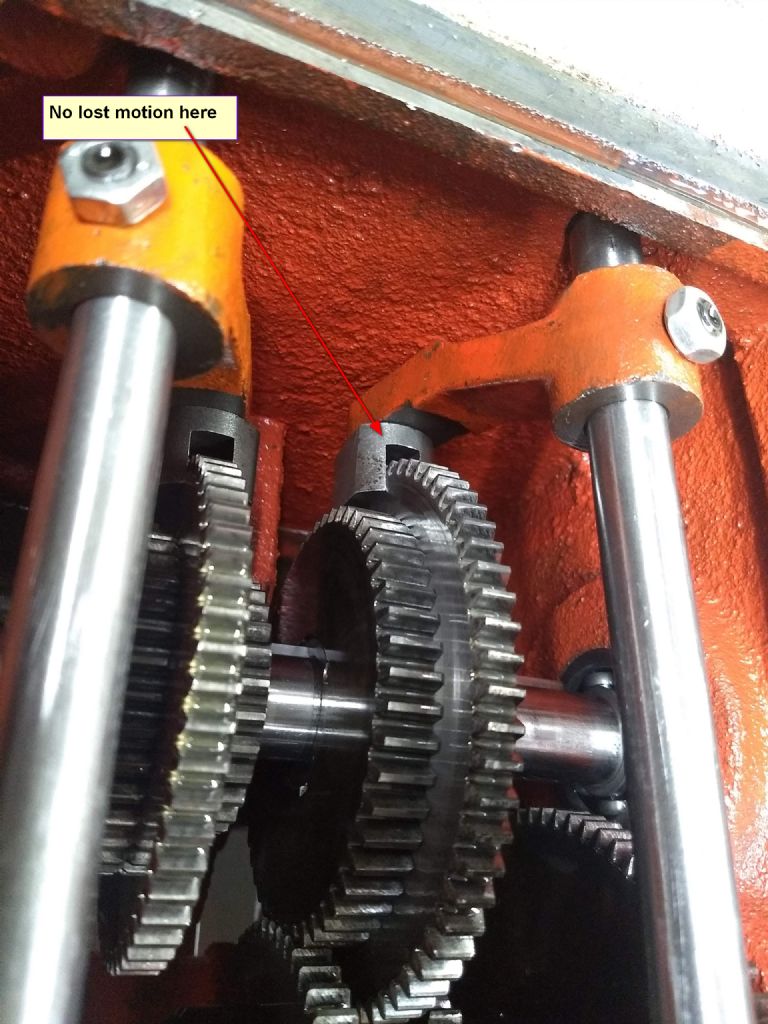

***EDIT*** There was no noticeable wear on the fork.

Edited By Gary Wooding on 29/12/2022 12:15:08

Bazyle.

Bazyle.