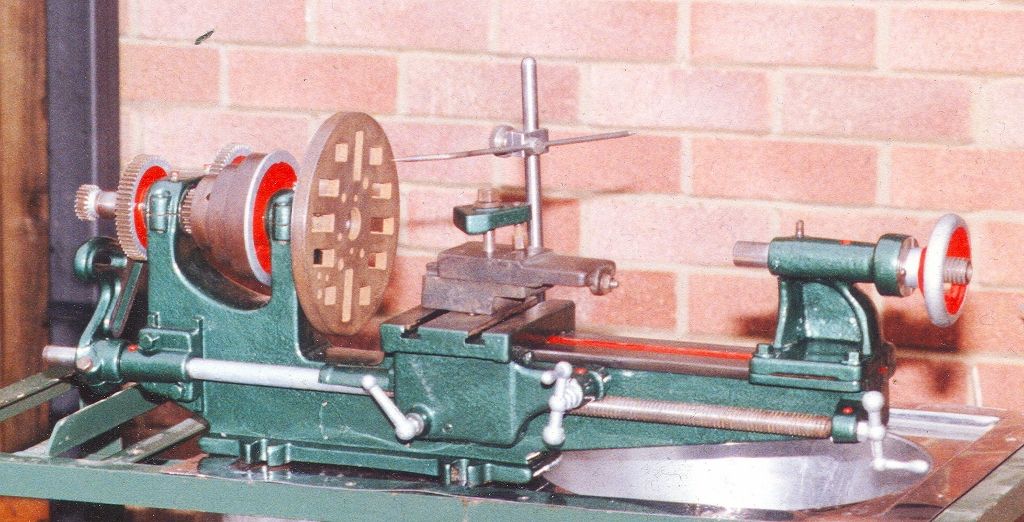

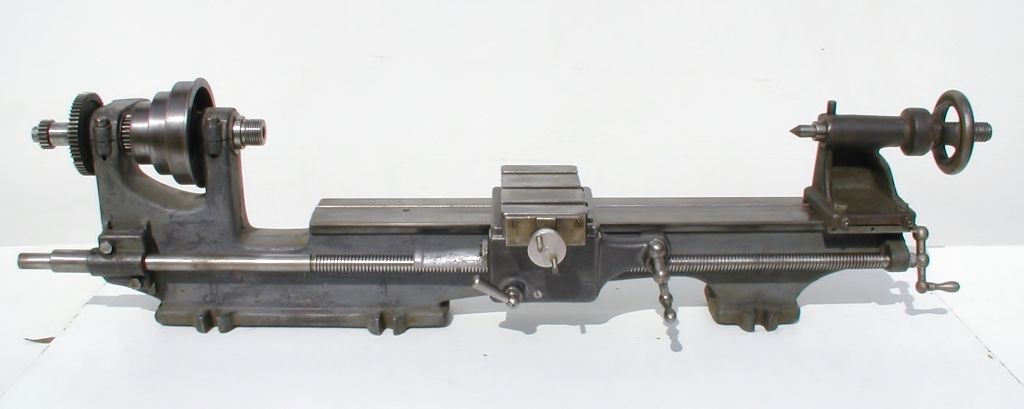

Hi Reggie, as it happens, I still have my fathers RandA model B lathe as shown below, when i gave it a strip down, clean and a repaint, about 28 years ago, which looks the same as what you have.

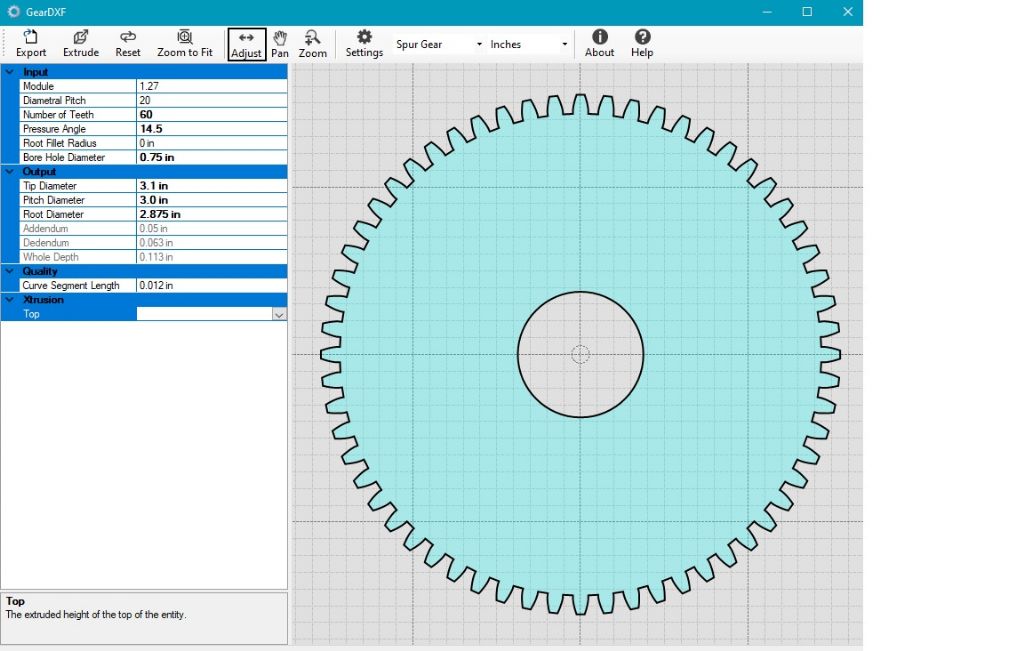

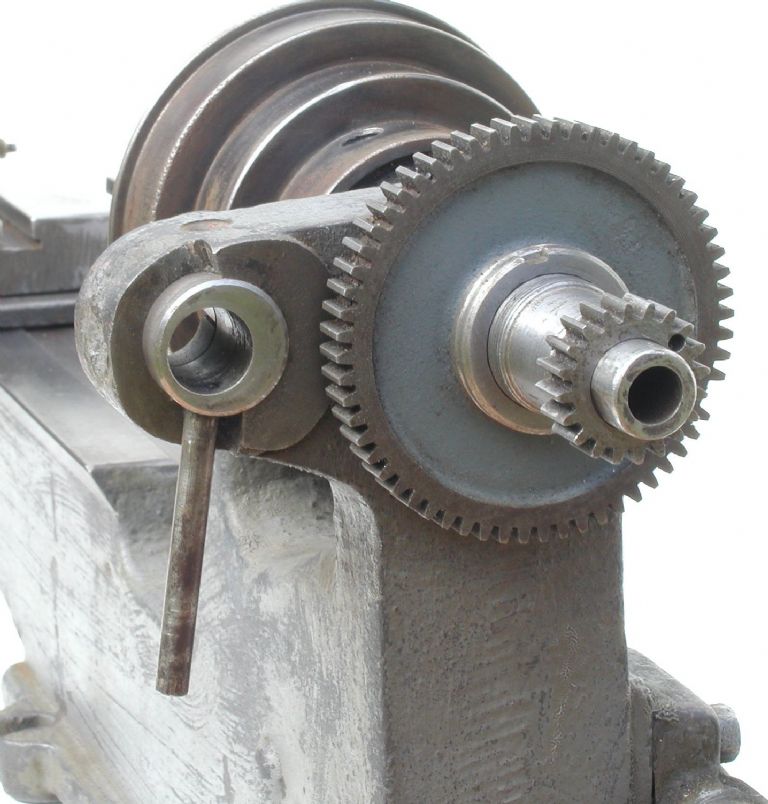

You will be very lucky to find a gear that you have missing, so you will probably have to make one or get one made by somebody. Although the gear wheel is a 60 tooth 20 DP with a 14-1/2 degree pressure angle, it will probably be slightly larger O/D than your 60 tooth change wheel, assuming you have one of those, but it should be the same O/D as the one on the back end of the spindle.

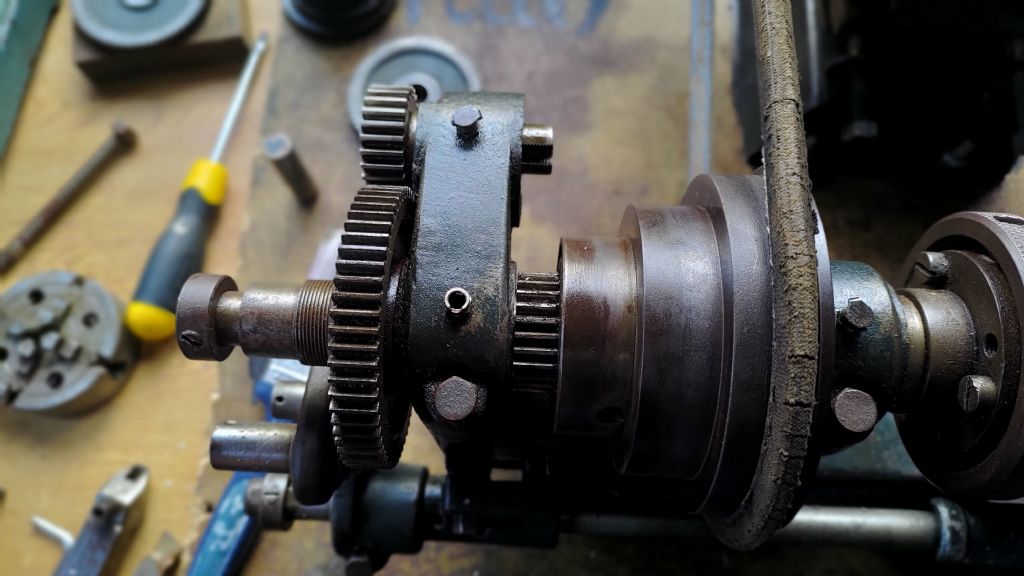

I have measured the one on my lathe and the O/D is 3.184" (80.9mm or there about) and the width on the teeth is 0.409" (10.4mm), but the boss portion is about 0.482" (12.25mm) but flush with the teeth side at the back.

If you would like a photo or two of it, let my know.

Regards Nick.

Bazyle.

Bazyle.