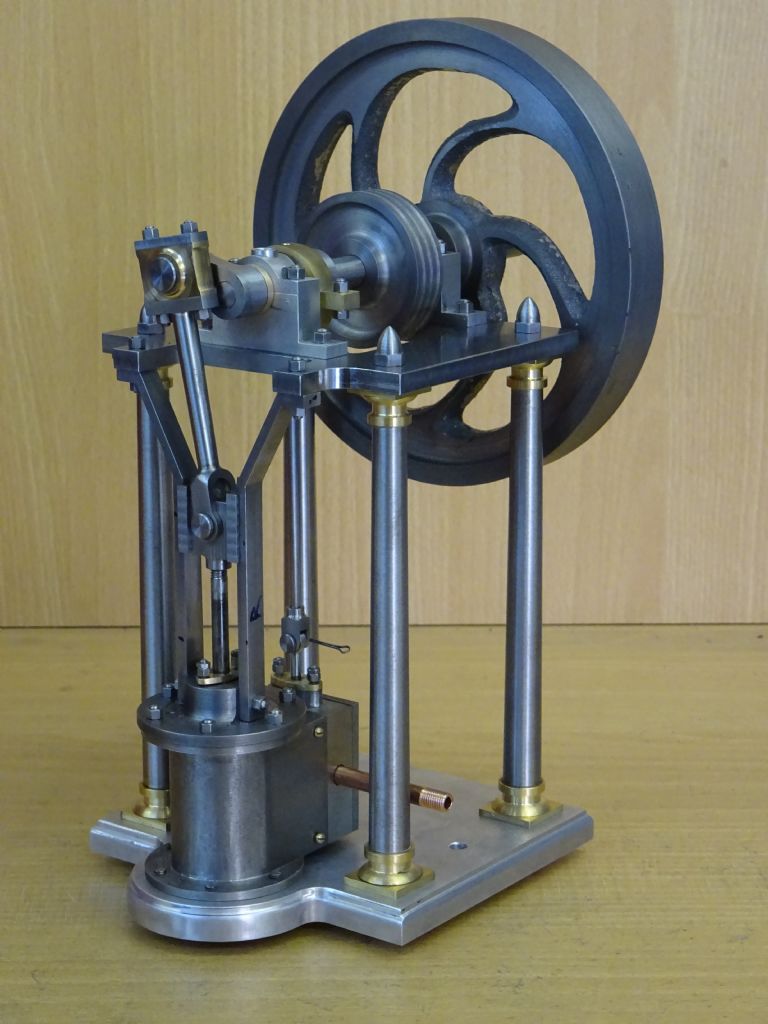

Posted by Colin Heseltine on 30/07/2019 21:05:38:

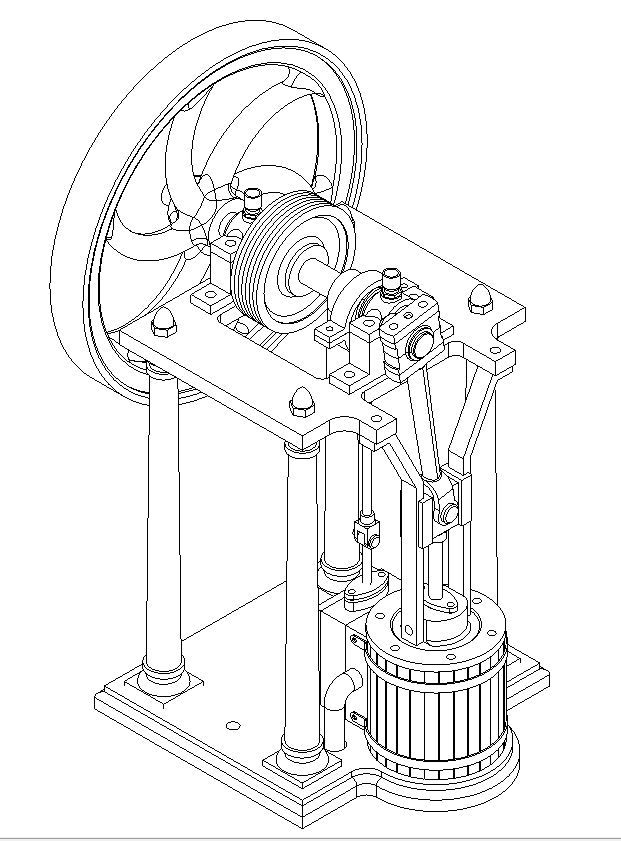

Do you have any video showing how you produced the radius around the cylinder mounting on the base plate and then changed from external radius to internal radius's and achieved it all nicely flowing from one radius to the next.

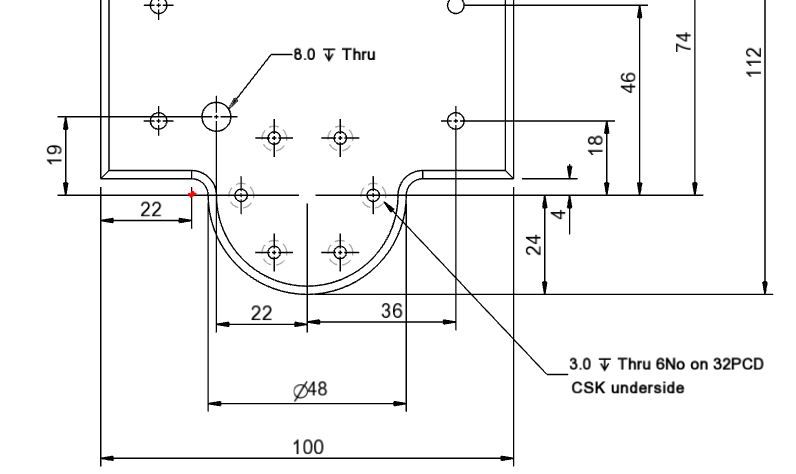

Looking at the drawing at the bottom left of the base is a dimension of 22mm in from the edge to the ctr of the internal corner radius which I have marked in red which gives a distance from the cylinder Ctr datum point of 28mm (half base width less 22mm) in the X-axis and zero in the Y-axis. As the front edge of the base is 4mm from this point an 8mm cutter can be used as per the text.

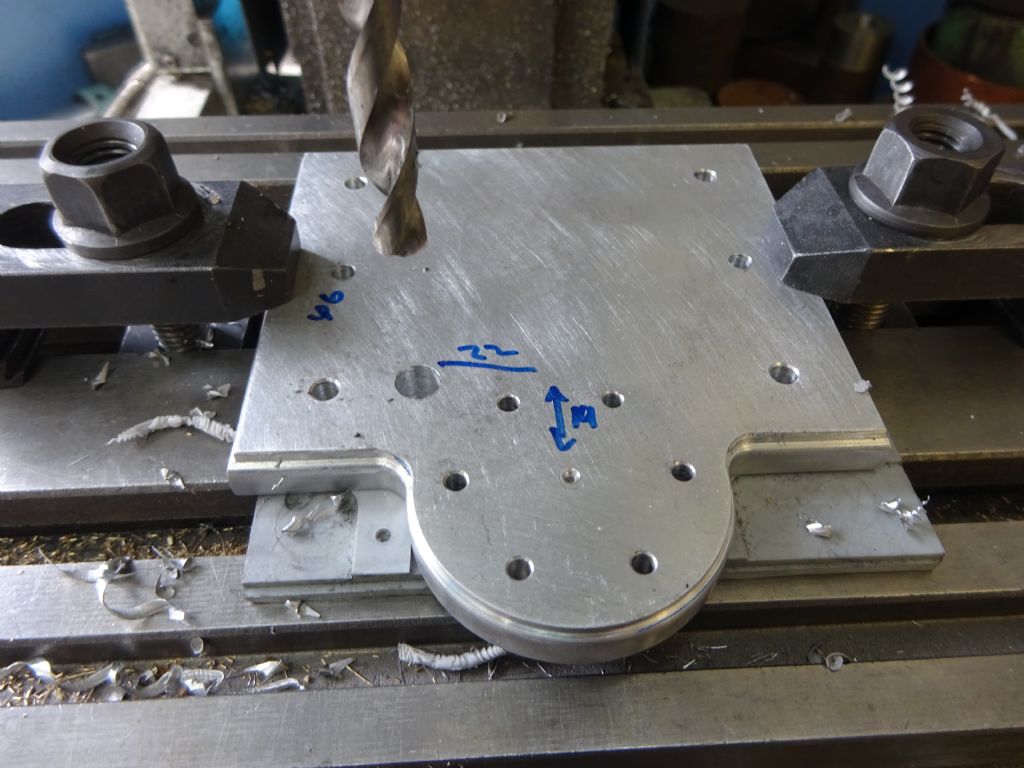

First thing to do is set the rotary table up on the mill with it's axis directly below that of the mill and zero your handwheel dials or DRO. Then turn the table until the scale reads zero and clamp the work to the table with some packing between and make sure it is square to the lathes axis and the ctr of the cylinder is lined up to the mill spindle.

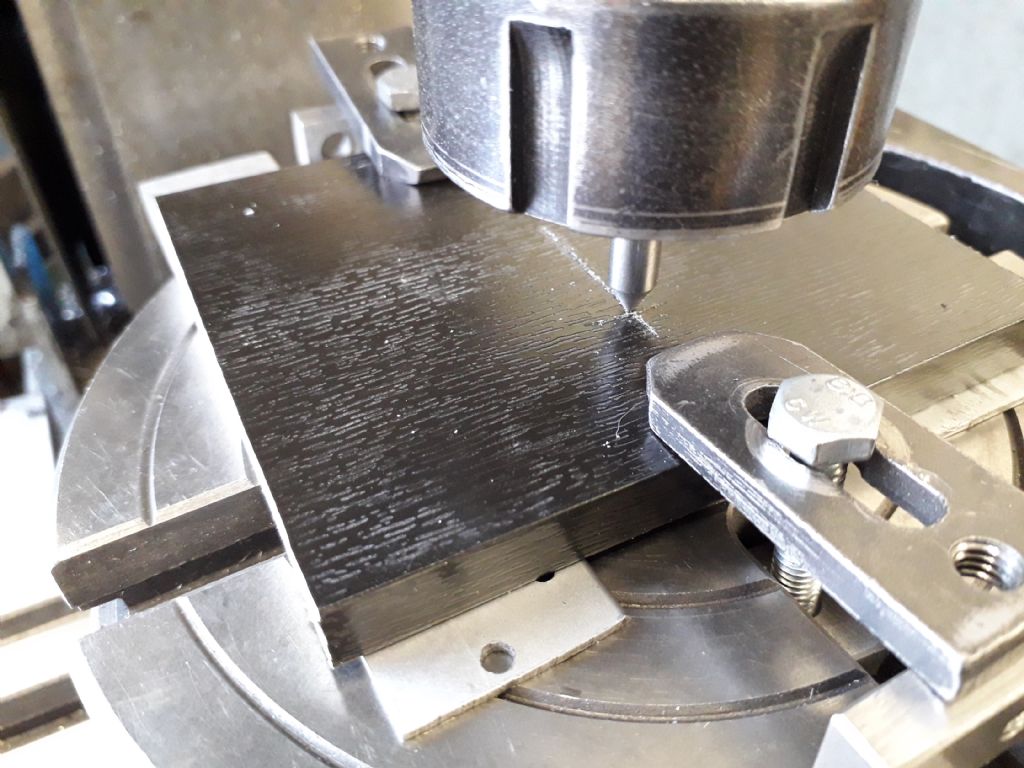

Pop an 8mm cutter in your holder of choice, lock the Y-axis at zero and then cut in from each edge to 28mm from the cylinder ctr. Assuming a bench top mill then something like 1mm deep per pass will do or more if you have sawn away most of the waste before milling. You should then end up with two slots like this.

Reposition the clamps to the sides and you can now also lock the X axis at -28, 0 and bring the cutter back down to take your first cut around the curve which will start from zero degrees and end at 180deg, repeat this until you have cut ring through and hopefully have a shape like this. before rushing to admire your work run the decorative moulding around the curve and front edges while the work is correctly located.

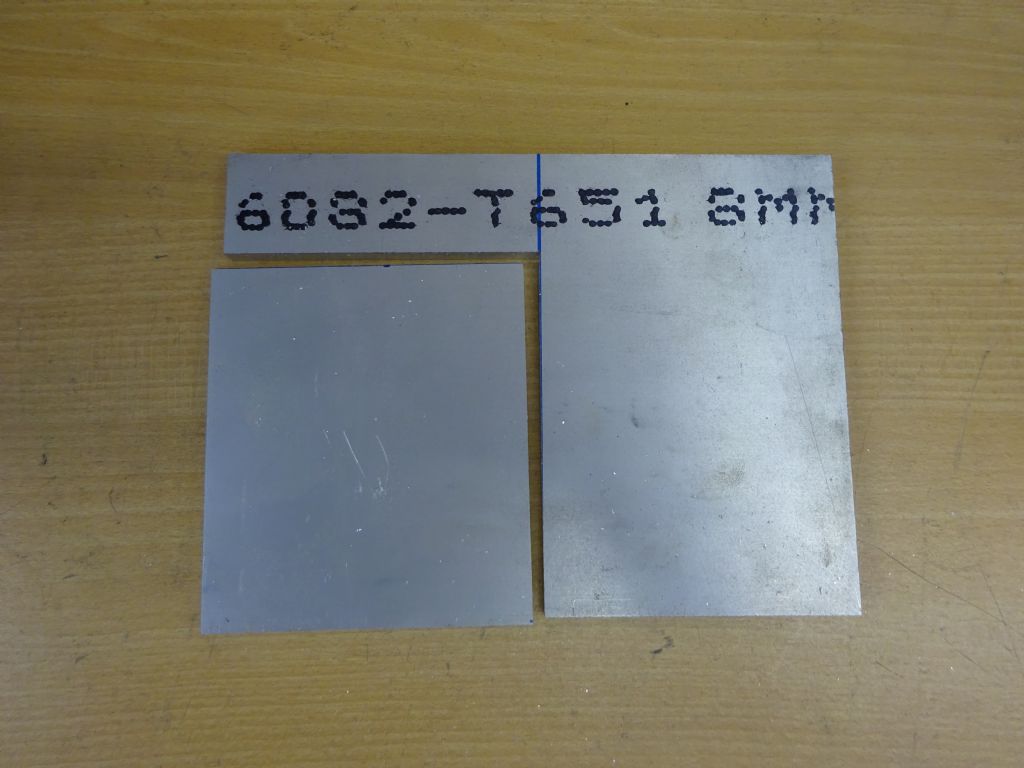

Do not dispair if you don't have a rotary table, just mill the two slots and then saw and file the half circle. If you take this approach it would be better to build up the base from a piece of 6mm plate that can then have the 2mm moulding filed onto it and then add a 2mm thick plate ontop that is 2mm smaller all round to produce the quirk.

JasonB.

JasonB.