I've now made almost all the piece parts, but I'm stuck for a method to make the slot through the piston rod end for the key and wedge that hold on the bigend strap.

In the bigend strap, I could cut the 1/16 x 5/32 slot using the pilot of a centre drill, which cuts on the flutes as well as the lips. The strap is U-shaped and thin, so the pilot was long enough.

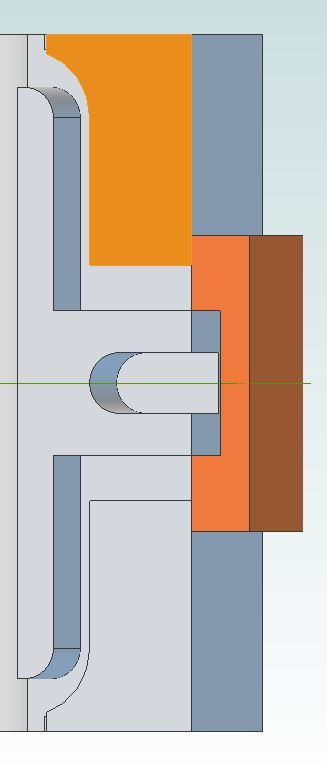

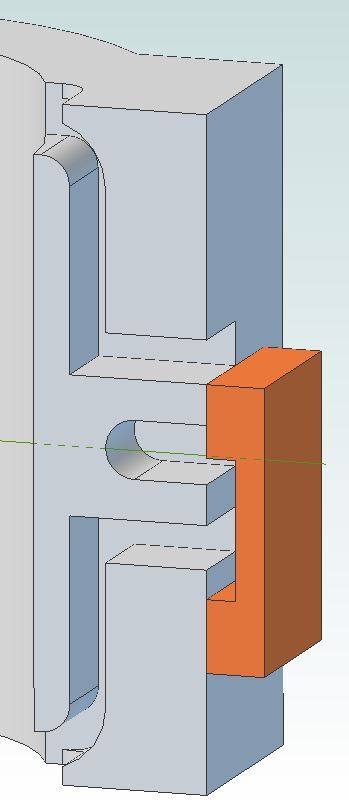

But the piston rod end has a concave radius to fit the lower half of the split-bush bearing, and another 1/16 wide x 5/32 long slot right through the 1/4" thick flat, and the little centre drill pilots are nothing like 1/8 long so won't do.

I haven't any spark-erosion kit. I'm wondering about drilling a line of contiguous 1/16 through holes, milling between them as much as I can from both sides with the centre drill pilot, then grind up some sort of punch with an angled face to try to chisel/scrape/broach away the hole segments the pilot can't get at in the middle.

But that has every prospect of ending up looking like it was carved from an old potato by a drunken sailor.

Anybody know of a simple way to do this?

I'd post a scrap view of the drawing, but have seen that Anthony Mount posts on here and don't want to provoke any copyright issues…

Edited By Mick B1 on 14/05/2018 19:55:07

Jon Lawes.

Jon Lawes.