Dear All,

Dear All,

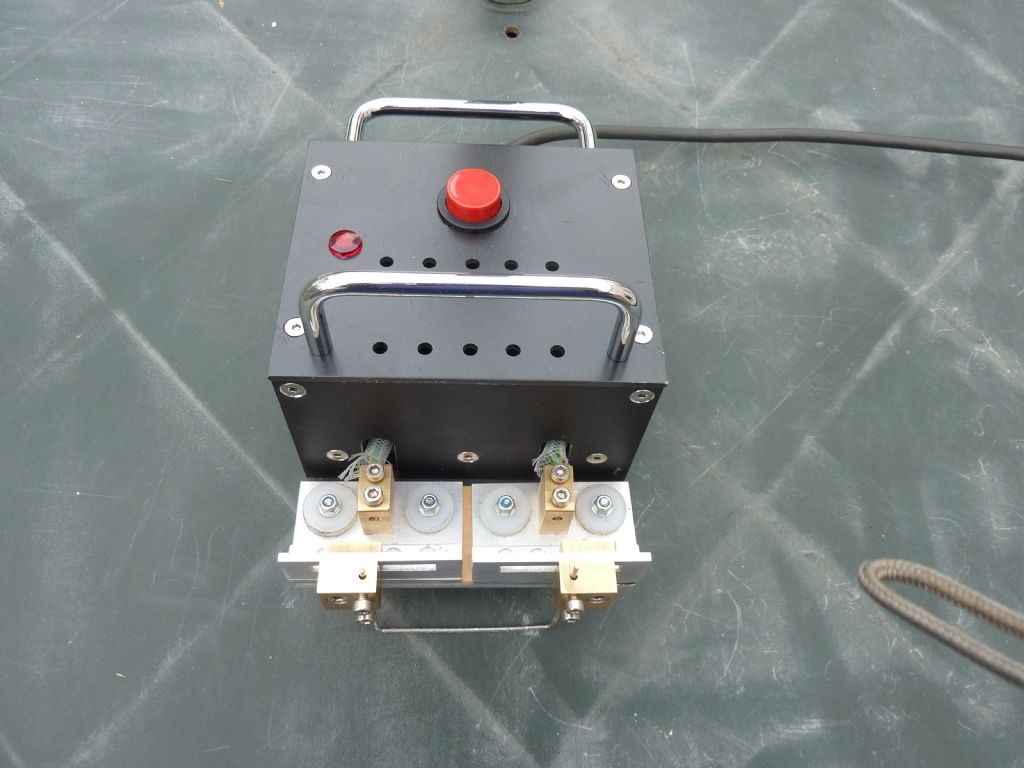

I have finished my Polystyrene cutter and tested it on some scrap pieces, The building extension has been postponed until the spring of 2018 so it has not done any proper jobs as yet.

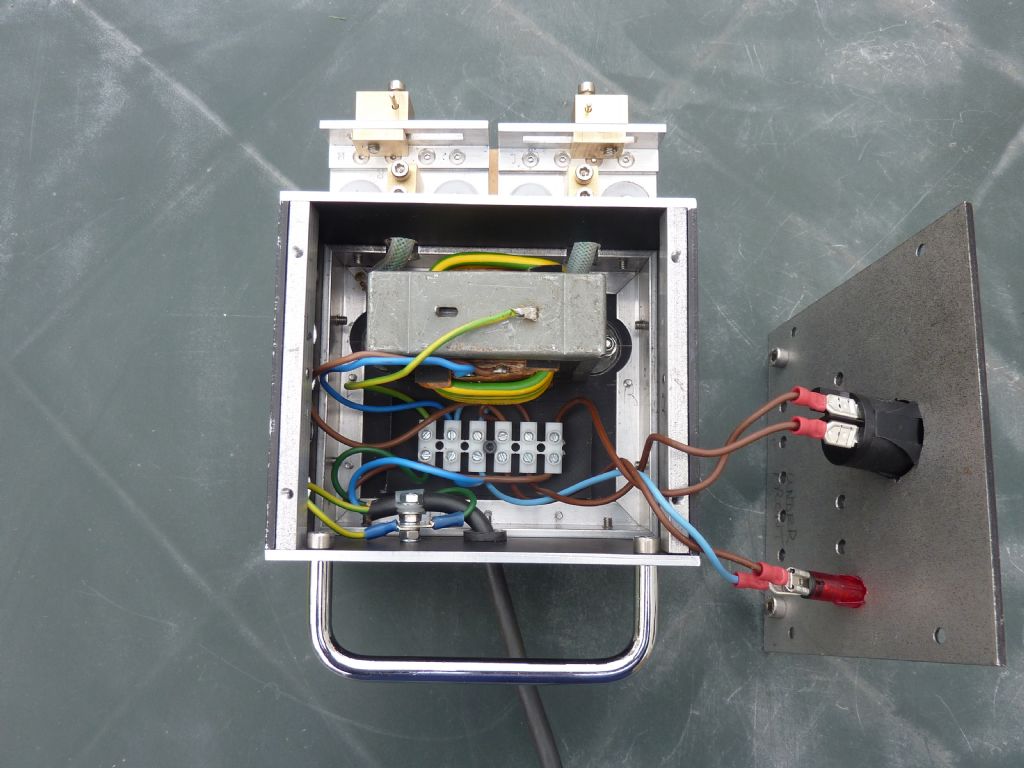

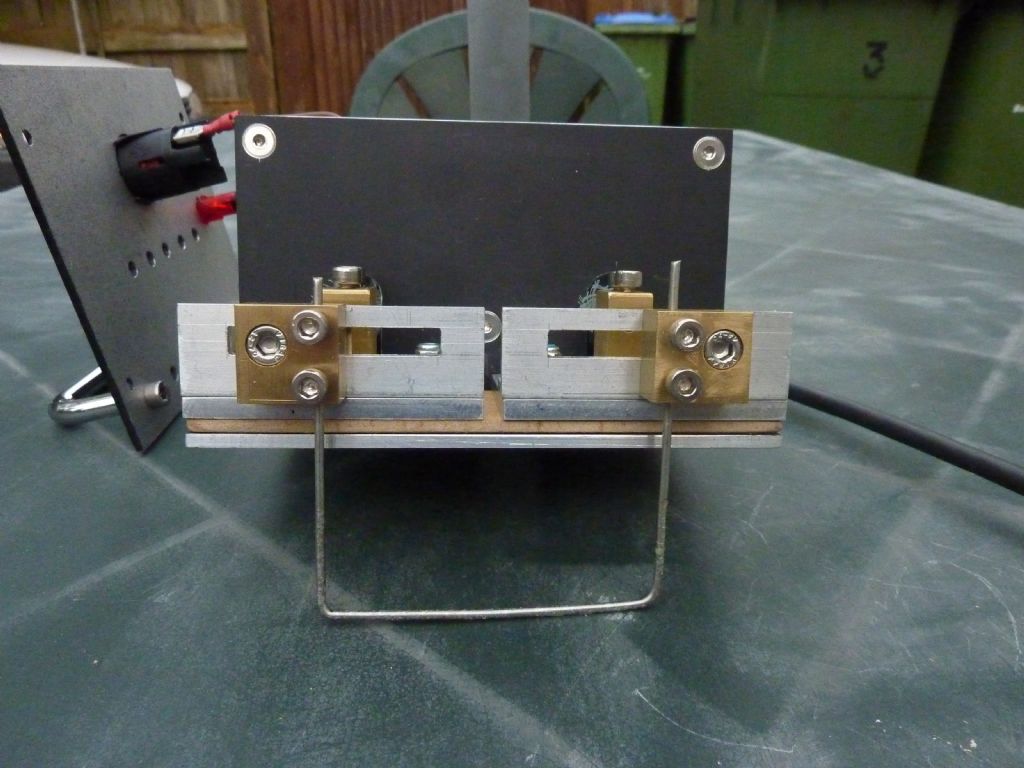

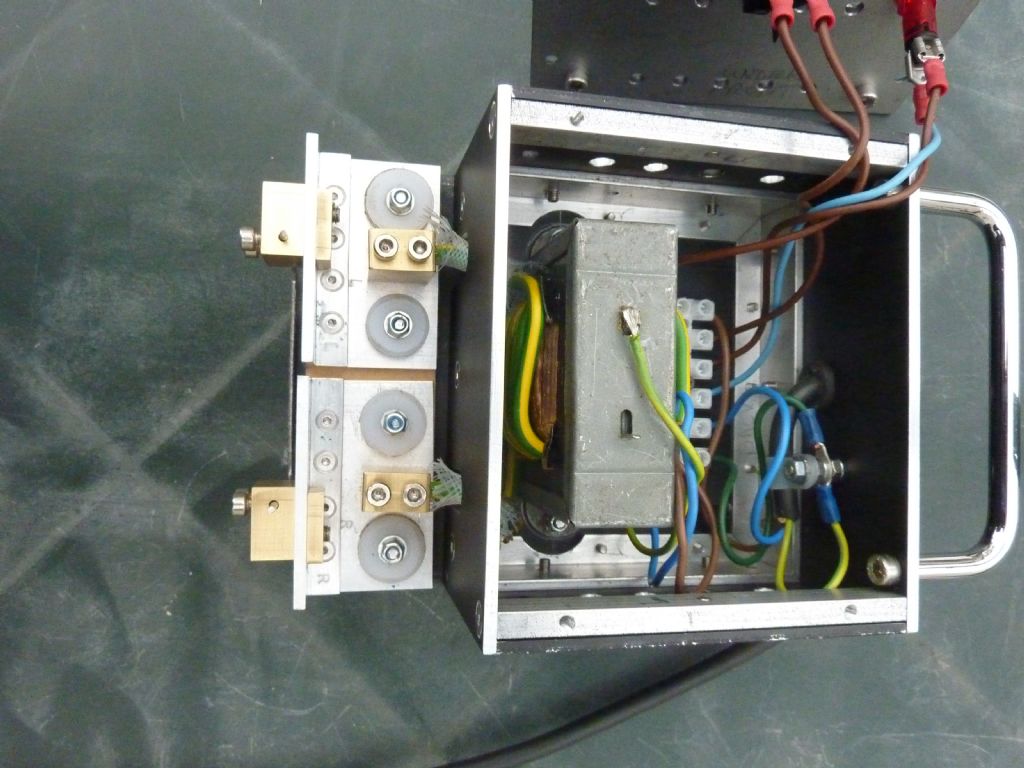

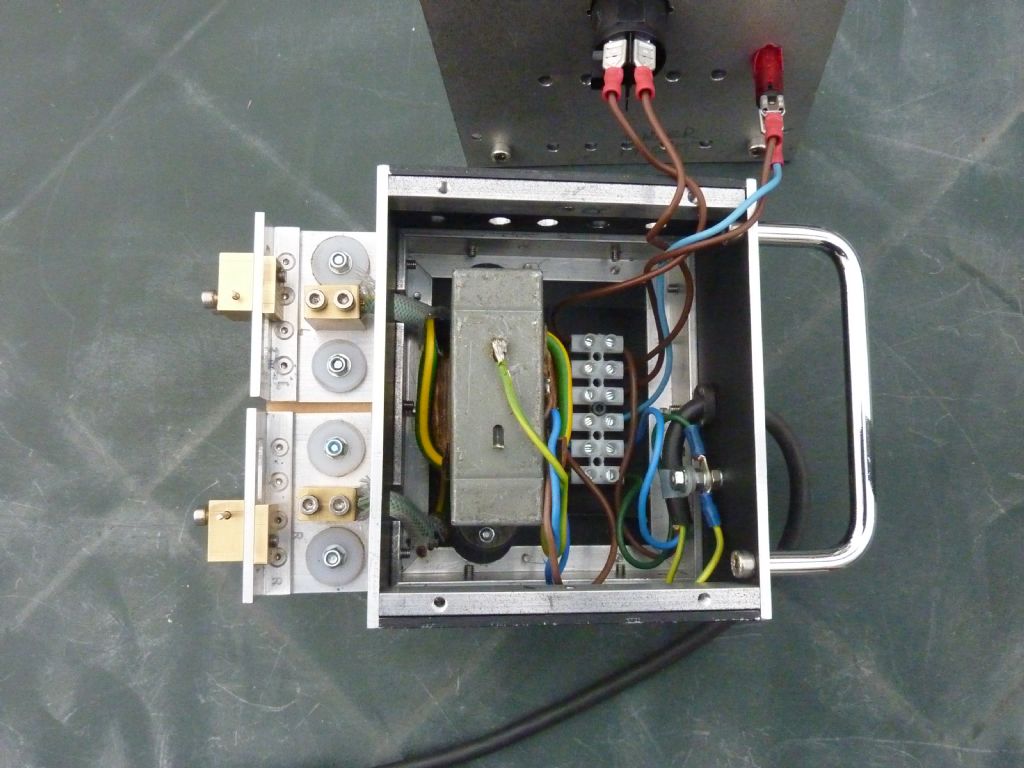

It has two handed operation to ensure accuracy of cuts and arm fatigue, the thumb of either hand can hold down the ON button, it heats and cools very quickly, there is a red neon to show when it is heating, the width and depth of cut is adjustable, it has two cutting wires one for the fitting of conduit and the other for the box for the sockets.

The Voltage output is 1.4 volts, the cutting wire is 14 guage Ni-Chrome, I found this the best for cleaning after using, the residue scraped off with a finger nail, other metals required the use of a tool. The secondry winding was eventually 7 turns of 60mm square wire that is normally used as earth cabling ie green/yellow.

A Tip is that after dismantling the original TX secondry windings and reassembled the laminations it is possible to feed and wrap the new wire round the former, this makes it easy to experiment with different turns and you can get more on.

Hopefully some pictures will now appear!

paul sims.