Single to 3 phase inverter problem

I converted my Bridgeport to 240v in 2005. I ripped out most of the electrics in the control box and replaced the contractors . The inverter was purchased on eBay

The motor was wired up as on the plate for low speed, which at the time I took to be 240 v (Probably not correct). The machine ran so I didn’t try any other connections. I used the varispeed on the 2JB head and ran the inverter at 50 Hz. The motor is two speed when running on 440 v 3phase and it has 9 wires.

The inverter failed in 2009 and was replaced, but when purchasing the new one I was informed the old one could be repaired, at a cost of £20 a capacitor was replaced by them and it worked! The engineer commented that it was a very old inverter. I sold it.

Now the 2009 inverter has failed Of course it was in the middle of an important job! All the ancillary electrics work ok

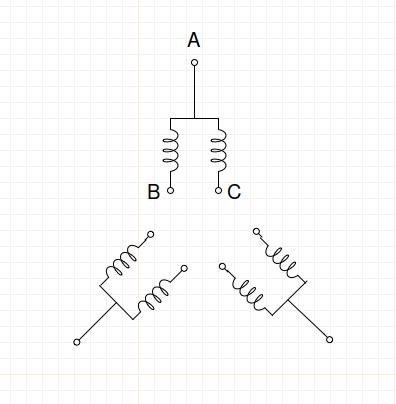

So some investigation was needed. It seems I wired the motor to a choc block as in fig. 1 from the motor plate as shown in fig.2. It seems that this connection as shown in Wikipedia is a modified star as shown in fig 3. As the motor should have been wired in delta as in fig 4 it should not have run at all!..

But here is the conundrum, this diagram shows 6 coils so there should be 12 wires not 9. Some must be connected internally, or is it that I just don’t understand the workings of the two speed motor.

fig 5 shows the coil resistance at 2.4 ohms for all but 7-9 and 7-8 @ 4.1 ohms

I have tried unsuccessfully to sort out the diagram to account for this and the grey matter is spinning! I do not know what the colour coding means on the 9 motor wires

It is the inverter which has failed , I connected it to my drill motor ( 3 phase as well) and it just jigged back and forward even with u,v &w interchanged

I will probably get an upto date vector inverter rather than a straight VFD which will cost considerably more.

In February this year, I had to replace a part in the head and made the mistake of switching the rotary switsc from forward to reverse on initial testing. This I know is a big Nono the machine worked ok, but it was noticeable that for a while the motor seemed a bit hesitant to start but it has been worked hard during lockdown.

I don’t want to cook another inverter , so can anybody help with the connections please . I have viewed a lot of manuals and wiring diagrams, but none seem to match my setup.

Thanks.

Thanks.

Edited By Zan on 10/10/2020 16:07:00

Martin Bryars.