This was how I did my Wyvern flywheels:

File off all the flash and and any lumps on the faces of the rim.

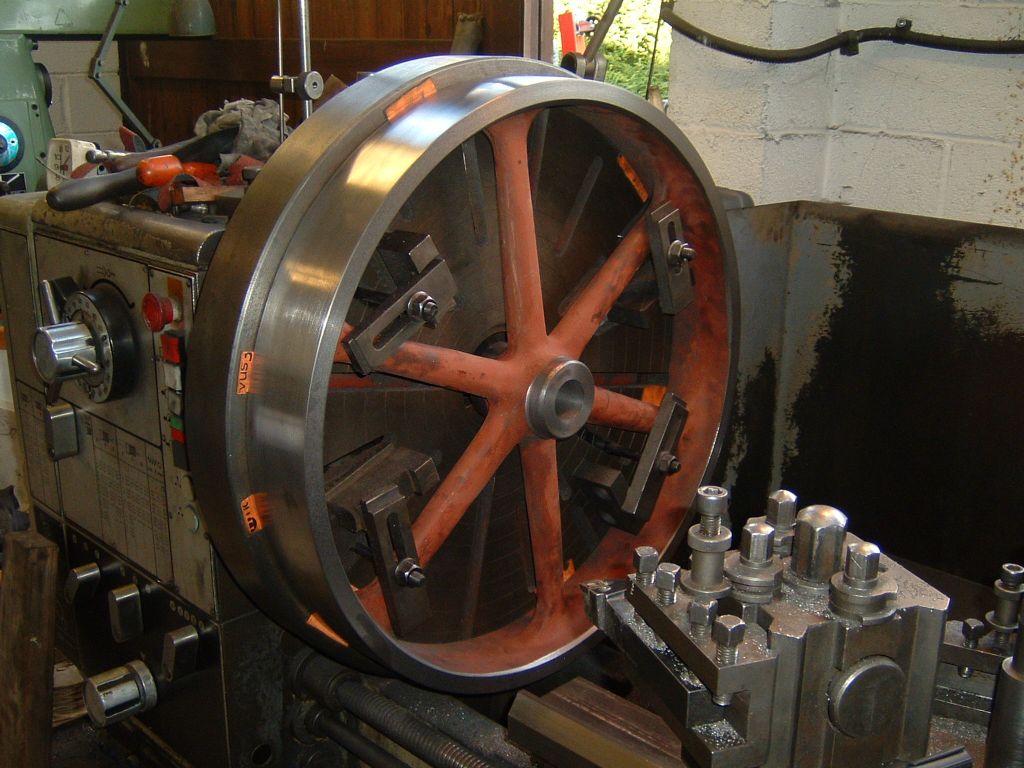

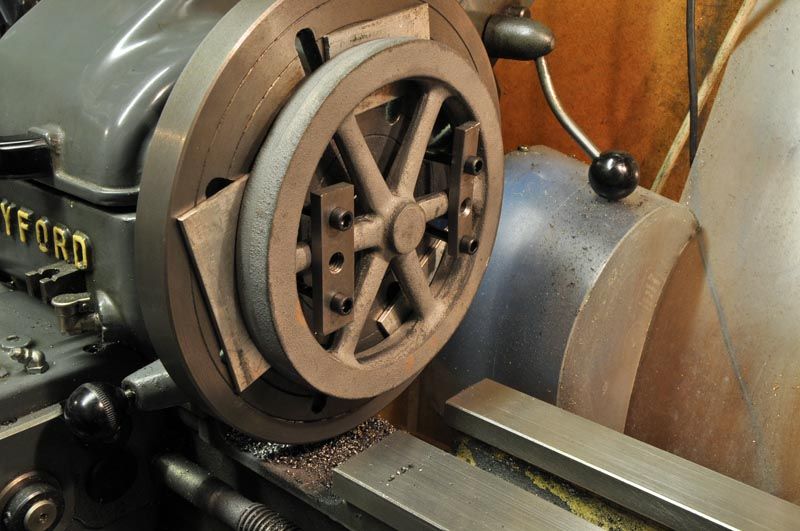

Most flywheels are cast with a split pattern so registration between the 2 halves may not be perfect. Choose a side to be the "outside" i.e. the side that the engine will be mostly viewed from. Mount this side out on the faceplate with 3 sacrificial pads (ally in this case). Try to get the inside of the rim running as true as possible. Take a cut across the face of the rim and the circumference.

Now reverse the flywheel and centre on the faceplate using a DTI on the rim circumference

The sacrificial pads allow you to take a cut across the whole of the rim circumference

The video shows a mis-registration problem. The "good" side of the rim was fine but you can see the eccentricity on the reverse side. Not too bad for the Wyvern since this has twin flywheels so both of them can be mounted with the good side on the outside – less easy to hide on a single flywheel steam engine.

Hope this helps,

Rod

Edited By Roderick Jenkins on 19/05/2014 19:42:15

mechman48.