Id previously came across someone else who had problems with low resolution printer tape while trying to use it for a linear scale so left that one alone. I also recently came across an ic which read magnetic tape but decided that would need a quite a lot of development to make it into a working linear encoder?

The common ebay Chinese rotary encoders appear quite well made and seem to come in a few different specs with pulse per revs ranging from 360, 400 and 600 with a great lack of manufactures info in the traditional manner. However some listing have snippets of info, like

Pulses: 600 p/r (Single-phase 600 pulses /R,Two phase 4 frequency doubling to 2400 pulses)

Output :AB 2phase output rectangular orthogonal pulse circuit, the output for the NPN open collector output type

So it looks like a 600ppr one is capable of 2400 pulses/rev quad? Assuming that, from a quick stab at a calc I make the drum dia around 0.75” to give 1 thou resolution with 0.5mm stainless wire? I’m sure someone will correct me but it seems a starting point to try when the encoder arrives and I can rig something up to try it on the mill with the leadscrew sensor as a standard as suggested.

Also the outputs appear to use open collector npn transistors which need a load resistor (1k etc to +5v) to give out the correct waveform?

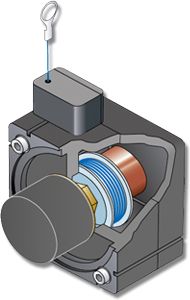

Agree a draw wire sensor not ideal but its not terribly expensive to give it a bash and I used the BW electronics one successfully for years.

Peter

Michael Gilligan.

Michael Gilligan.

, then take off the wire diameter. 3200 edges is 800 slots, it isn't clear to me how many slots your encoder has.

, then take off the wire diameter. 3200 edges is 800 slots, it isn't clear to me how many slots your encoder has.