Let's do some simple arithmetic.

Original requirement was to provide RSU with about 3 volts, it would draw approx. 10 amps. So absorbed power is 30 watts. Possibly a bit light but it feels in the right ball park. Think of a 30 watt soldering iron – would this cut the mustard? Note the phrase " of the order of 10 amps" – properly this only says the current is somewhere between 1 amp and 100 amps! Need to nail this down a bit to do some meaningful calculations, so take the nominal values for the time being.

Equivalent resistance of the RSU is then 0.3 ohms (ish).

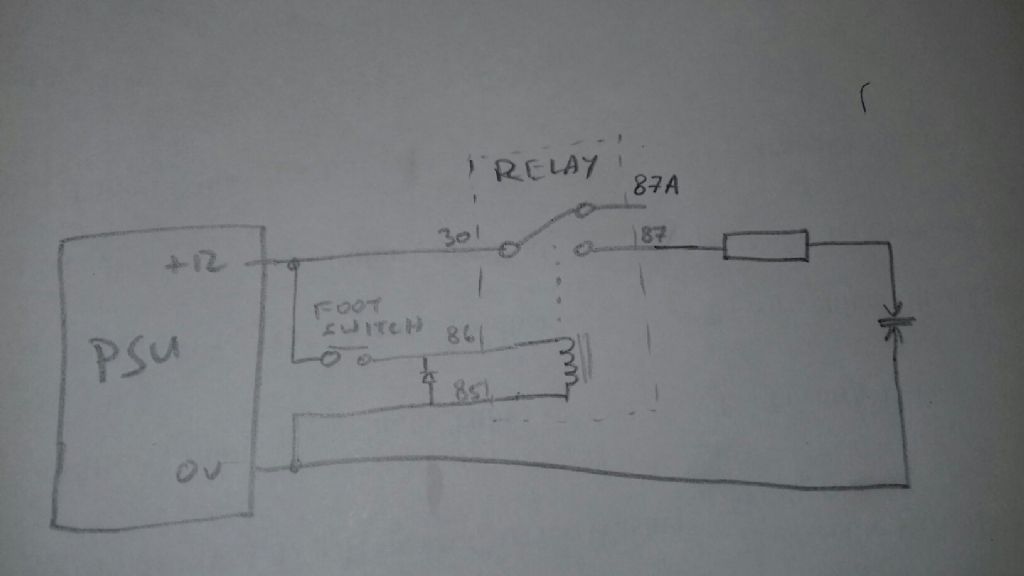

So we want to supply the RSU from a nominal 12 volt source. PSU needs to see 1.2 ohms total load for the load to draw 10 amps.

RSU accounts for about 0.3 ohms, so we need an additional 0.9 ohms in series with the RSU to end up with a circuit drawing 10 amps when supplied with 12 volts.

0.9 ohms isn't a preferred (standard, purchasable) value, so stick with 1.0 ohms as series ballast resistor for the time being. Moderates the load current to 9.2 amps.

Power dissipated by 1.0 ohm ballast resistor is 85 watts (I squared R), but only for the duration of the current flow. Suggest that the current flow will be less than 50% of the time, so average power dissipation is say 40 to about 50 watts. That said, the ballast resistor needs to have sufficient thermal mass that it doesn't reach its melt-down temperature during the time the current is flowing.

Suggest the ballast resistor needs to be one of those aluminium bodied plate mounted things, if you are going to buy one then stick with 100 watts dissipation, mount it on a moderate sized heat sink, try it and see. Remember that by adding a second resistor in parallel you reduce the overall value of the resistance, (product over sum rule for parallel resistances) and adding a resistance of 10 ohms in parallel will give you an effective resistance of (near enough) 0.9 ohms. The parallel trimmer resistance dissipates much less power – approx. 10 watts – so this "trimmer" resistor can be of a smaller power dissipation.

Putting two 1.0 ohm resistances in parallel halves the effective resistance i.e. 0.5 ohms, plus 0.3 ohms inside the RSU makes the load 0.8 ohms, supplied by 12 volts draws 15 amps, heading towards the max output of your fancy PSU. Dissipated power in EACH resistor is now 7.5 (volts) squared over 1.0 (ohms) equals 56 watts, but RSU terminal voltage rises to 4.5 volts. RSU absorbed power now 4.5 (volts) times 15 (amps) equals 68 watts, i.e more than doubled.

I've used the nominal 12 volts value of the input voltage so you can use the voltage adjustment of your "decent bench power supply" to fine tune the heat input.

Lots more arithmetic possible if we know the terminal characteristics of the RSU more accurately.

Hope this helps Simon

choochoo_baloo.