This is mainly for beginners who may be faced with a repetitive job and how a simple drill jig can help.

Faced with drilling a few hundred 6 mm holes in some 30 x 6mm steel rail, I made a simple drilling jig. The object was to have a jig mounted on the Mill/Drill and not move the jig, just the rail section. Each end of the rail needed two 6mm holes so that sections could be "fish plated" together. In addition, the same jig would be used to make the fish plates and also used to put holes into the sleeper ends.

Back to the rails.

The first photo shows a rail section in the jig waiting to be drilled. It is pushed up against a removable dowel pin on the right.

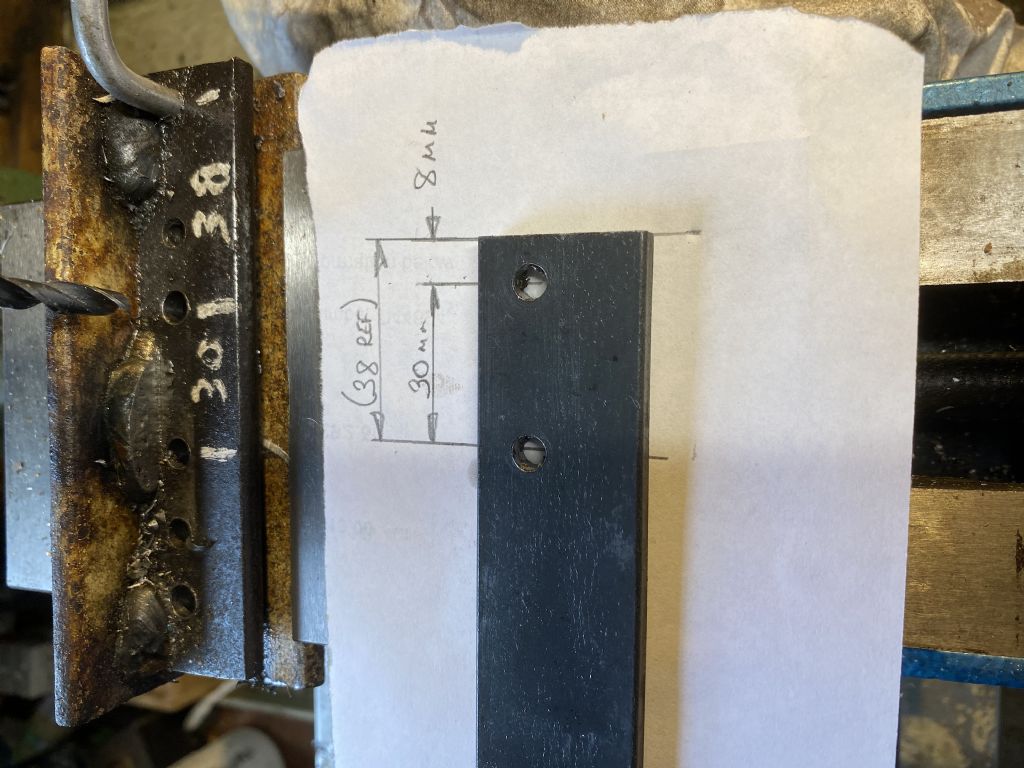

The next shot shows the measurements of where the holes are required

The next shot shows the measurements of where the holes are required

This one shows the first hole being drilled 38mm from the end of the rail. The rail is hard up against the dowel pin.

The last shot shows the rail moved to the left and a second dowel pin located into the first drilled hole (38mm from the end of the rail) ready for the second hole to be drilled 30 mm from the first hole.

All that is left is to turn the rail about (remembering that the holes are offset to the bottom edge of the rail !!).

Now off to weld the sleepers to the rail using another jig to space the sleepers in their correct position and space the rails the correct distance apart. A simple jig made of wood which is sacrificial and may get a few weld burns !

Peter Cook 6.