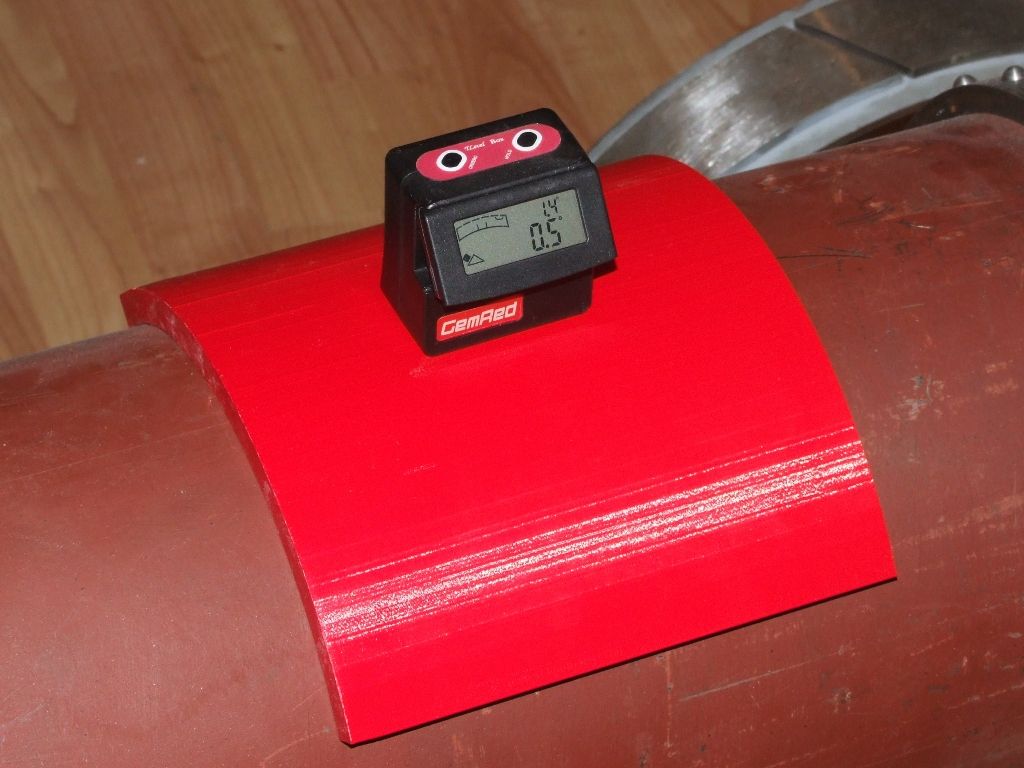

You can design in any scale you want and then scale to final size in CAD. Having said that I normally design to the finished size of the part. An exception is gears that are going to be machined on the CNC mill. In that case I design as 1DP and then scale accordingly. Personally I do any such scaling in the CAD system. When scaling a 3D print for shrinkage I use the slicing software for the 3D printer. One problem is that the shrinkage of the printed part is anisotropic and also varies with part size, shape and layer thickness. I've recently 3D printed a trial cylinder flange for my traction engine to check fit on the boiler:

I scaled this by 0.5%, which turned out to be generous, as the length of the flange is about 0.2% too long. I think that the shrinkage of parts created from liquid resin is smaller than parts printed from filament, if only because heat isn't involved.

I think you'll find that shrinkage in a casting is more complex than a scalar value. It will depend upon how the casting cools. Once part of the casting has cooled it isn't going to shrink any more, even if other parts of the casting around it are still shrinking – look up hot tears. The shrinkage will also depend upon any cores and how they fit within the casting.

Of course it all depends what sort of accuracy you hope to achieve, but it isn't always simply a case of applying an overall scale factor. For reference the flange above was about 14 thou oversize in 7 inches.

Andrew

lee webster.