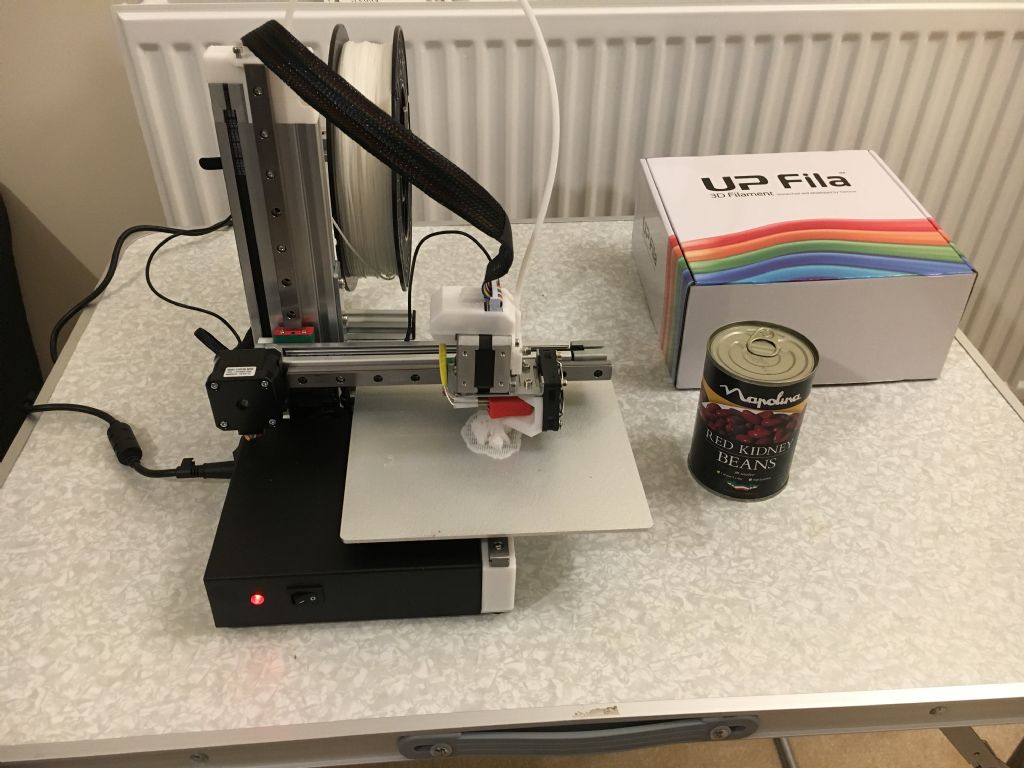

I was grateful to receive a Prusa 3D printer from my Son when he moved onto another design.

It performed ok but what annoyed me was the poor engineering :

1. Threaded rod and plastic parts to form the base for the bed.

2. Linear bearings held in place with cable ties (later models used U bolts on the bed bearings but that was not much better IMO.

3. Printing surface mounted on springs so that it could be adjusted to make it level. I accept that levelling adjustment is needed, particularly as the bed base plate cannot be relied on to be flat, but this introduces instability and side to side movement.

4. Stepper motors coupled to Acme lead screws with simple joints using grub screws (no flats on either as well).

5. The vertical frame was not braced in the original design.

6. The bed runs on 8mm dia rails that can only be supported at each end. This is not as rigid as it could be.

I accept that some of these issues have been addressed in later models but my mods so far include:

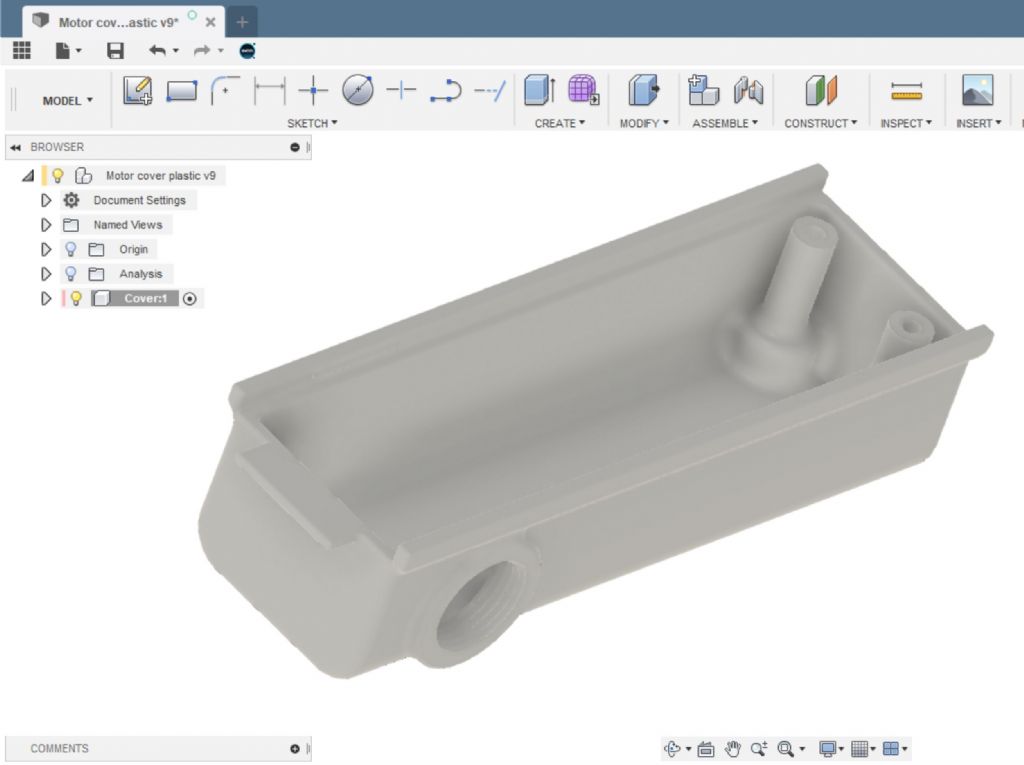

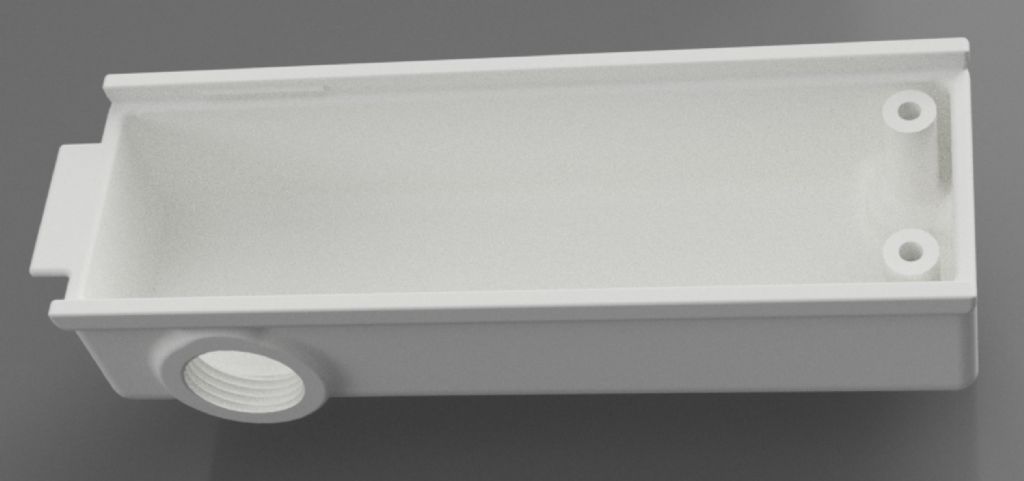

1. New base using 30 x 30 extrusion and aluminium end plates for the base.

2. Replaced all linear bearings with ones enclosed in housings that have mounting holes and made an aluminium X carriage to replace the plastic one.

3. Printing surface mounted with silicone spacers to give some adjustment, but with much reduced side to side movement.

4. Used Flexible Plum Couplings with a clamping action rather than grub screws to connect stepper motors to lead screws.

5. Braced the frame using aluminium supports.

6. I am about to replace the round rods and bearings on the bed with flat linear rails that can be supported along their entire length.

There are several other minor mods including those to wiring, belt fixings and tension adjustment etc. and I do get prints I am satisfied with.

I suppose my point is that a cheap printer is just a kit of parts as a base for development, like some of the cheaper Chinese machine tools judging by the number of modifications that appear in MEW etc.

John

I.M. OUTAHERE.