I have a CEL Robox – the reviews just don't do it justice.

It comes with proprietary software "Automaker" which is ultra ultra polished – smooth as a babies bum and super easy and intuitive to use. The interface is so simple its basically fool proof but behind it, it is just as configurable as any 3D printer and uses standard slicers to write the machine instruction which are a modified form of gcode (Cura is the default slicer). This software is just a simple installation, no setup required – take the printer out ofthe box, install the software (before you….) plug in the printer, load the fillament (poke it in a hole, and it detects it, and takes it off you, and feeds itself) – and then find a 3D model, and press print – wait, enjoy.

It also uses proprietary fillament spools, which come with the material data written on it (print speed, temps, bed temps, layer cooldown, everything – absolutely everything) – HOWEVER it's totally open, you can use whatever material you like, and Automaker even includes a module that lets you write and re-write the spools EEPROM and they give you their complete library of material print properties which they've researched and fine tuned.

The bed doesn't require any sort of preparation, you don't even have to clean it (although I give it a wipe with alcohol between ABS prints as it leaves a residue), parts stick first time, every time, I've only ever had 1 or 2 parts come unstuck. This applies to PLA, ABS, Polycabonate, all sorts.

The print heads are quick release, dual nozzle units with needle valves to control flow. The heads are either "quick fill" or "Dual Material" the quick fill has a fine 0.3 nozzle, and a wide 0.8mm, it does the outer detail in 0.3, and then quickly fills out the inner with the big 0.8 – saving time, which is the biggest enemy – a single large part can take a day or more, easily!!!

The hot end can hit 240c in just 1 minute from cold, and the heated bed will hit 130 in 4 minutes – this is roughly 1/3rd of the time of anything else ive seen. Further more, the nozzle will reach 280c max, and the bed will hit 150c which would actually melt most parts back down – however, its future proof!

Print quality exceeds that of the £30,000 professional solutions.

It's a very, very, very neat piece of kit – and the customer support is unbelievable, UK born machine, UK based customer support – I have a pre-production beta 3+ years old and it's just about to go back for a standard £100 full service, which will include any and all updates – even though it doesn't need anything it will get an new updated extruder and other tweaks and enhancements, plus anything it needs.

I could keep going on, if it exploded into a thousand pieces tomorrow – I'd go straight out, and buy another!

Edited By Russ B on 24/10/2017 20:52:34

Neil Wyatt.

Neil Wyatt.

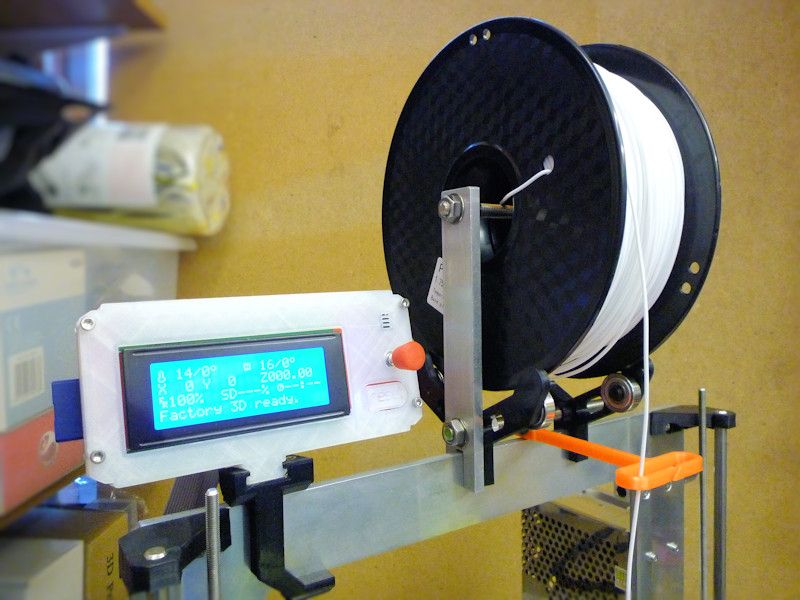

I will add an M5 hole to the frame for a securing screw, one day…

I will add an M5 hole to the frame for a securing screw, one day…