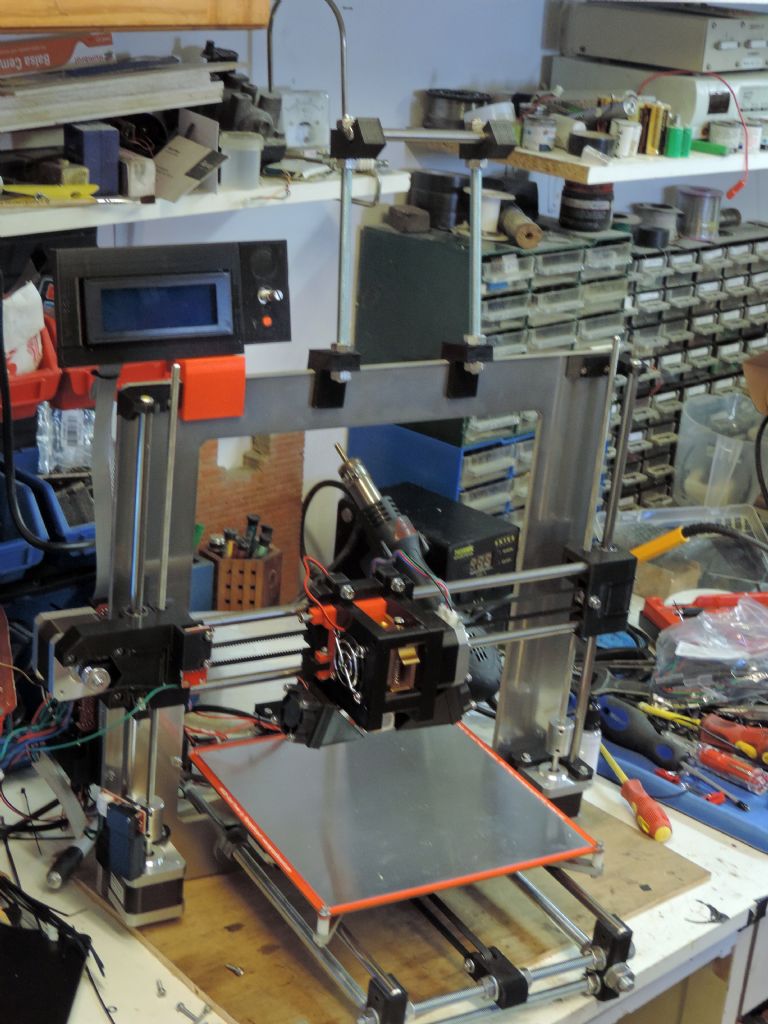

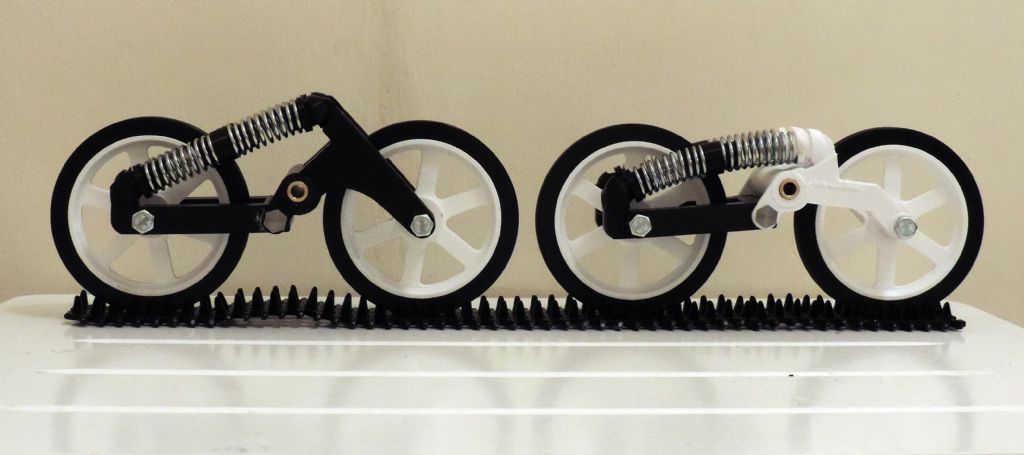

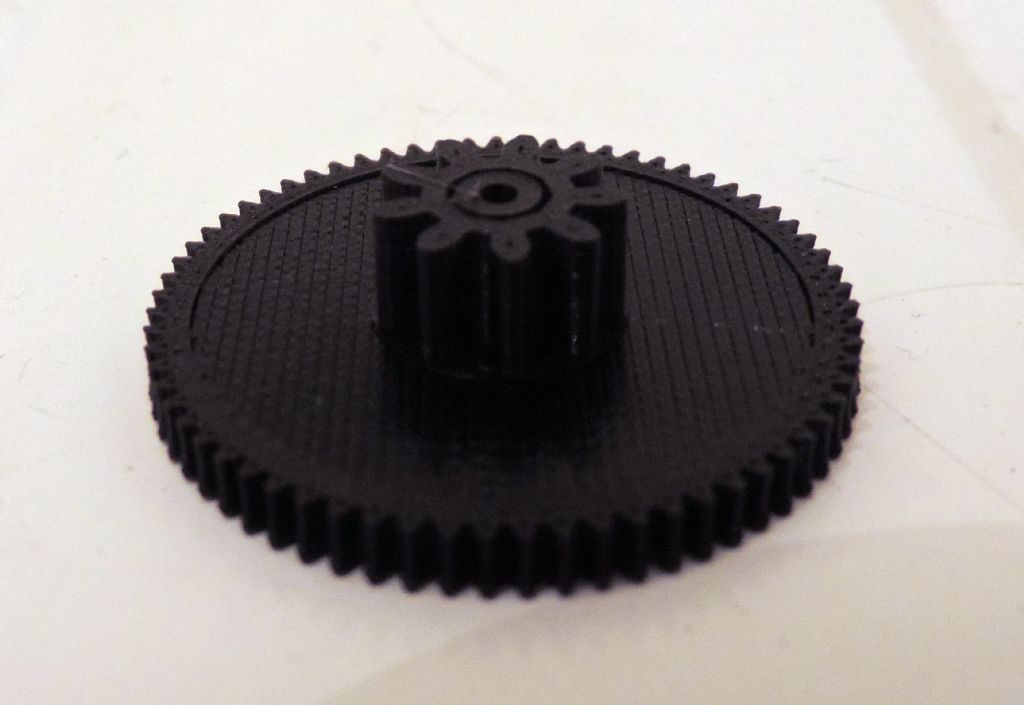

I redesigned my i3 and swapped the orientation of the X axis stepper to allow me to use shorter belts.

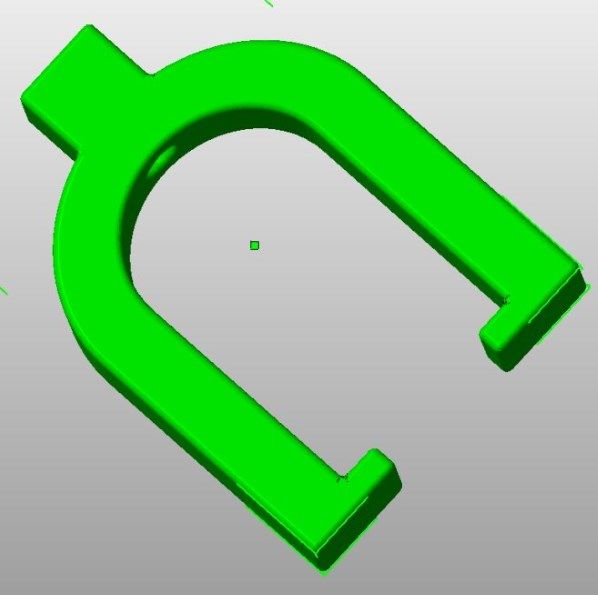

I have only ever used nylon tubing for my Z axis couplings and apart from one of them unscrewing itself on one occasion I have never had any issues with the Z axis.

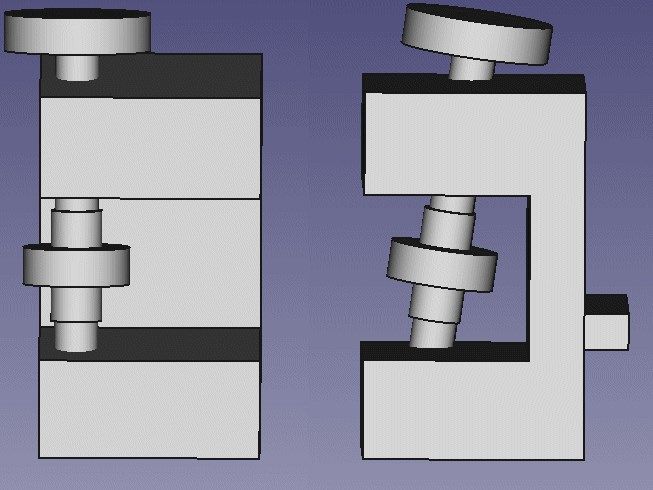

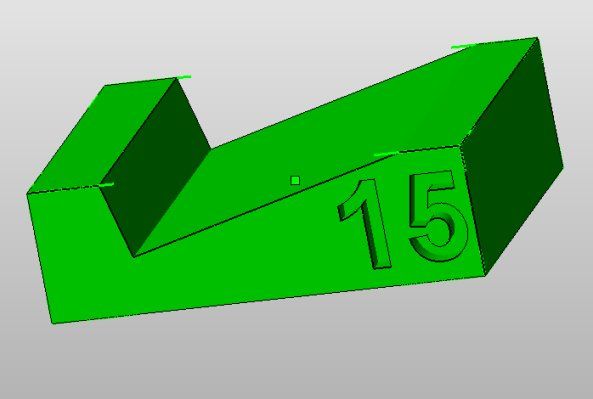

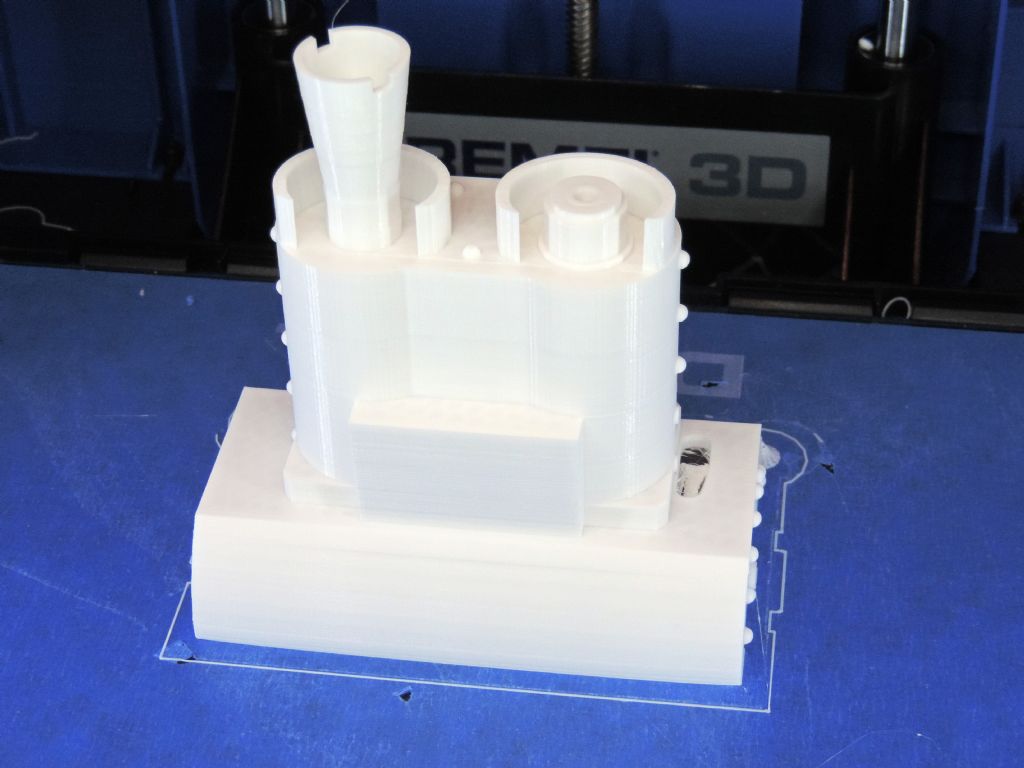

I added a tensioner to the X axis belt, as this was not easy to adjust as standard. I also switched to a Wades extruder from the bowden setup shown above.

By far my biggest issue is with back EMF from the relay that switches my heated bed on and off, causing the X axis stepper to miss steps every so often. I use a Sanguinololu board (because they are dirt cheap) but they do not really have suitable traces for running a 10A heated bed, so I took the control off board.

I use an Xbox 360 PSU for all power, I could probably resolve the issue if I split off the heated bed power from the stepper power with a separate PSU, but I can't be bothered at present, so I live with the issue.

Edited By Zebethyal on 19/04/2017 10:25:39

Paul Lousick.

ome people fit a toothed belt across the top and lose one stepper.

ome people fit a toothed belt across the top and lose one stepper.