The Fobco is built very solidly, out of substantial castings, and uses a very rigid spindle design, which includes a pair of angular contact bearings preloaded against each other, which is not unlike the arrangements used in many modern "hobby" milling machines.

Compared to a more modern drill press, that definitely qualifies as being over-built (as in the design and materials of construction significantly exceed the minimum required to do an acceptable job).

My experience using Fobco drills is also that the fit and finish of the quill and the bore it slides in is also unusually high by modern standards, as is the inclusion of a quill lock of the highly rigid split casting type.

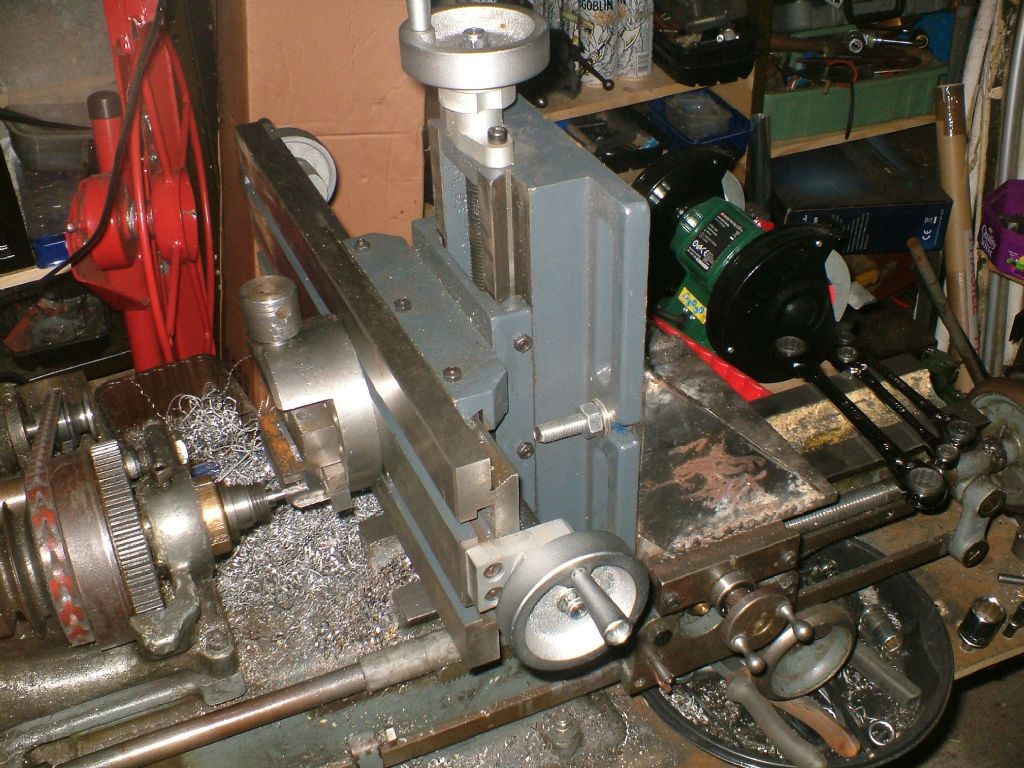

As such it is actually uniquely suitable to be re-engineered as a lightweight milling machine, in a way that very few drill presses actually are.

My big drill press is an early '90s Sealey with an MT3 spindle, and is far more capable as a drill than a Fobco star is, as well as seeming like a far more substantial machine…

But in reality it's internals have been heavily value-engineered to give maximum drilling for minimum money, so it would rapidly shake itself to bits if used for milling.

OP needs to be aware that not all drills are made equal, and if he wants to go down that route he needs to examine parts diagrams or sectional drawings to understand if the construction of the spindle is suited to conversion to milling.

Edited By Jelly on 11/02/2023 20:13:03

Andy_G.

Andy_G.